SIMULATION

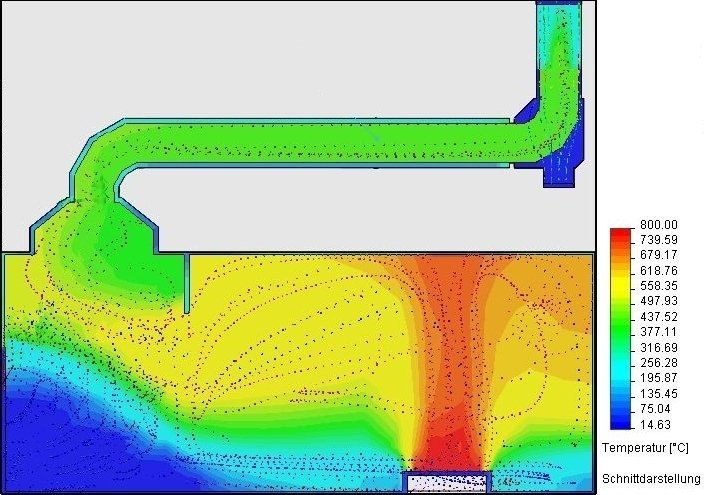

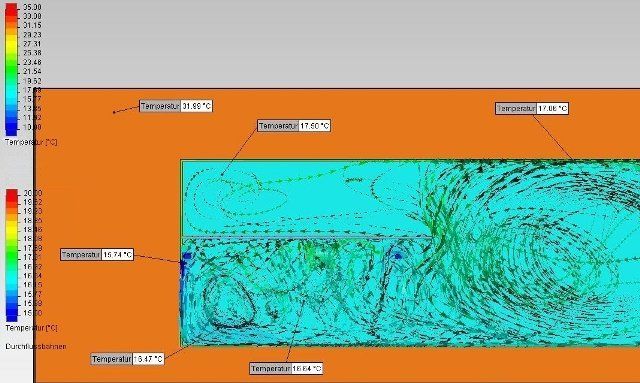

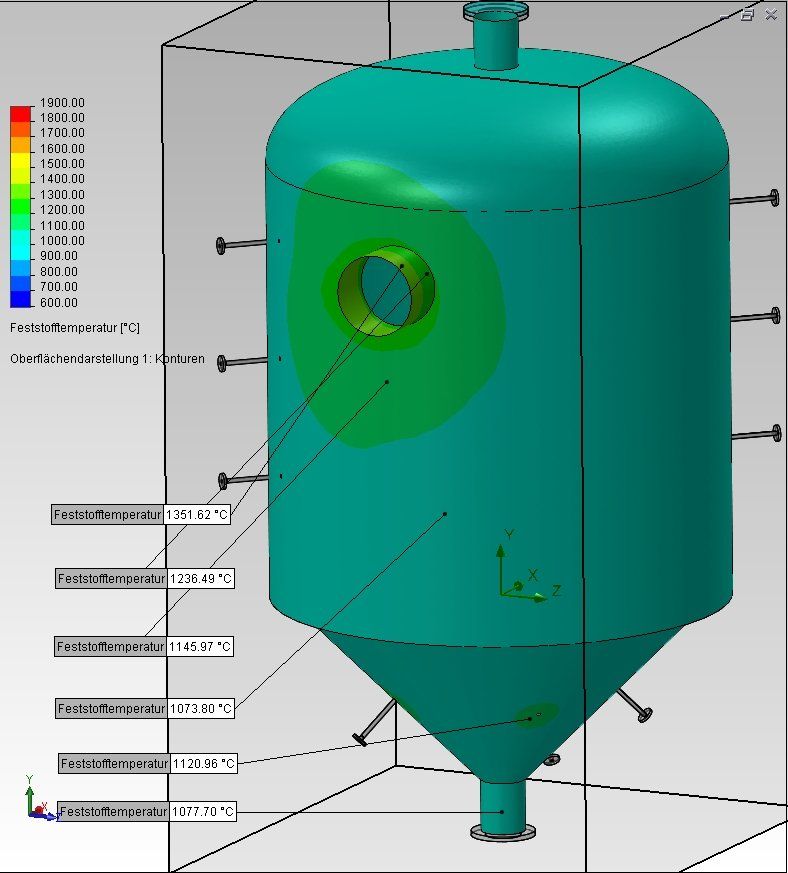

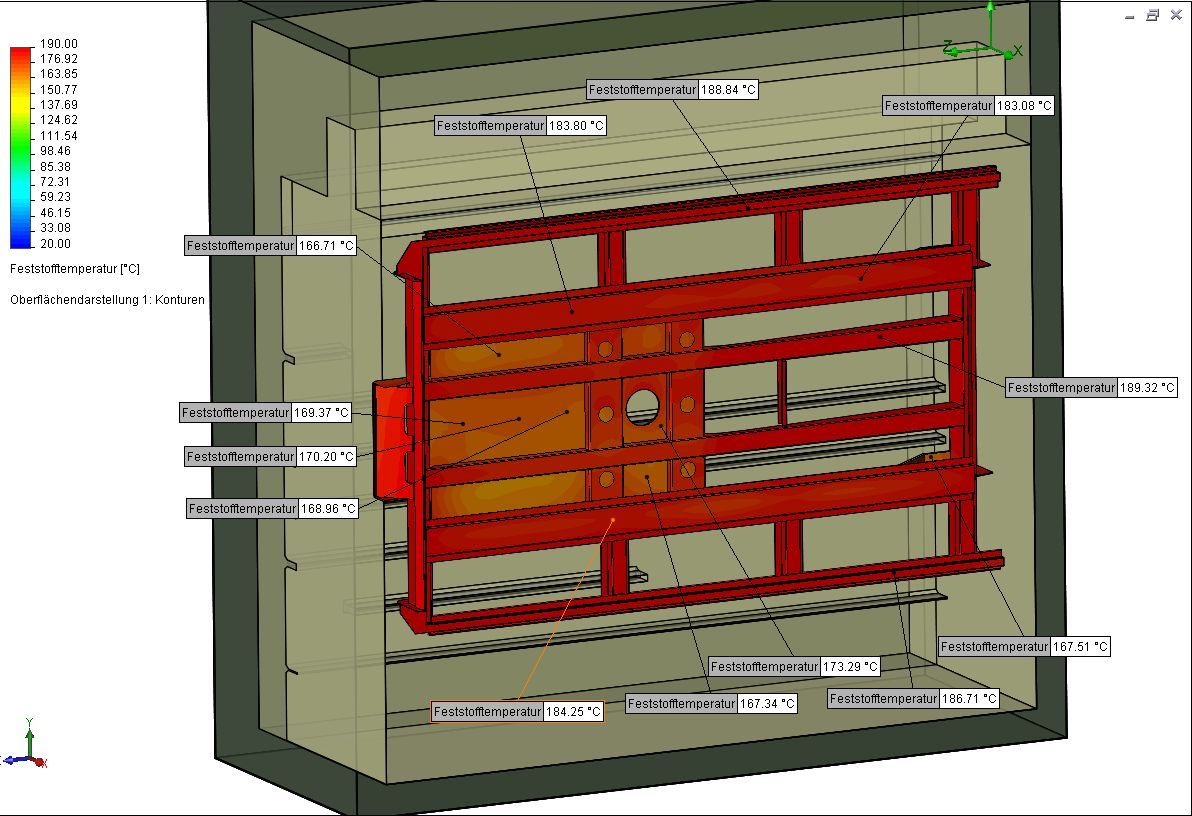

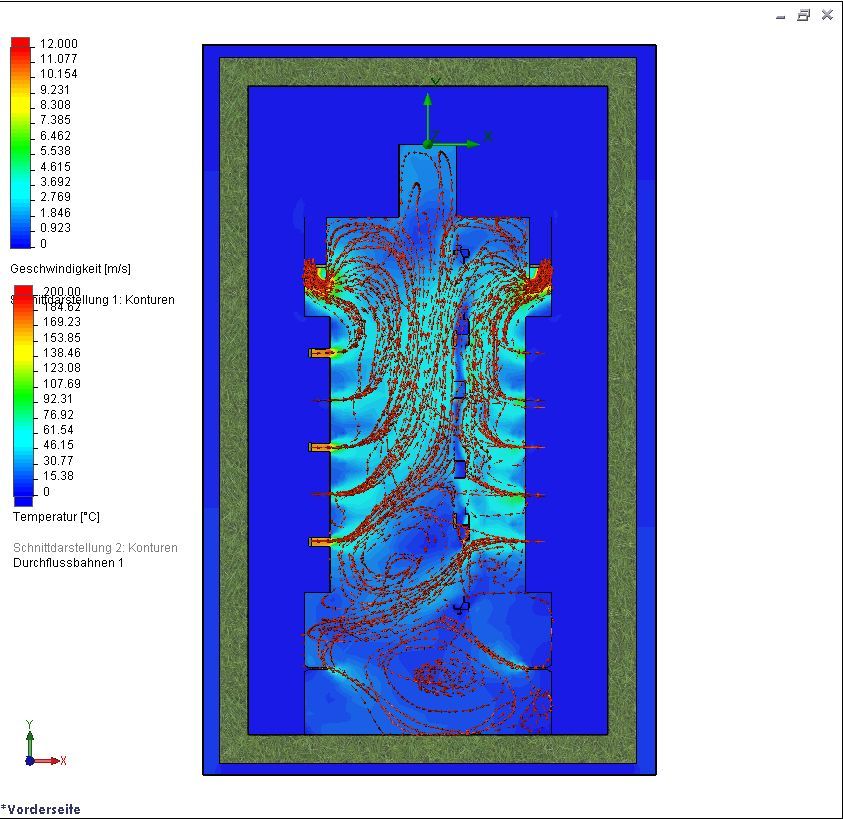

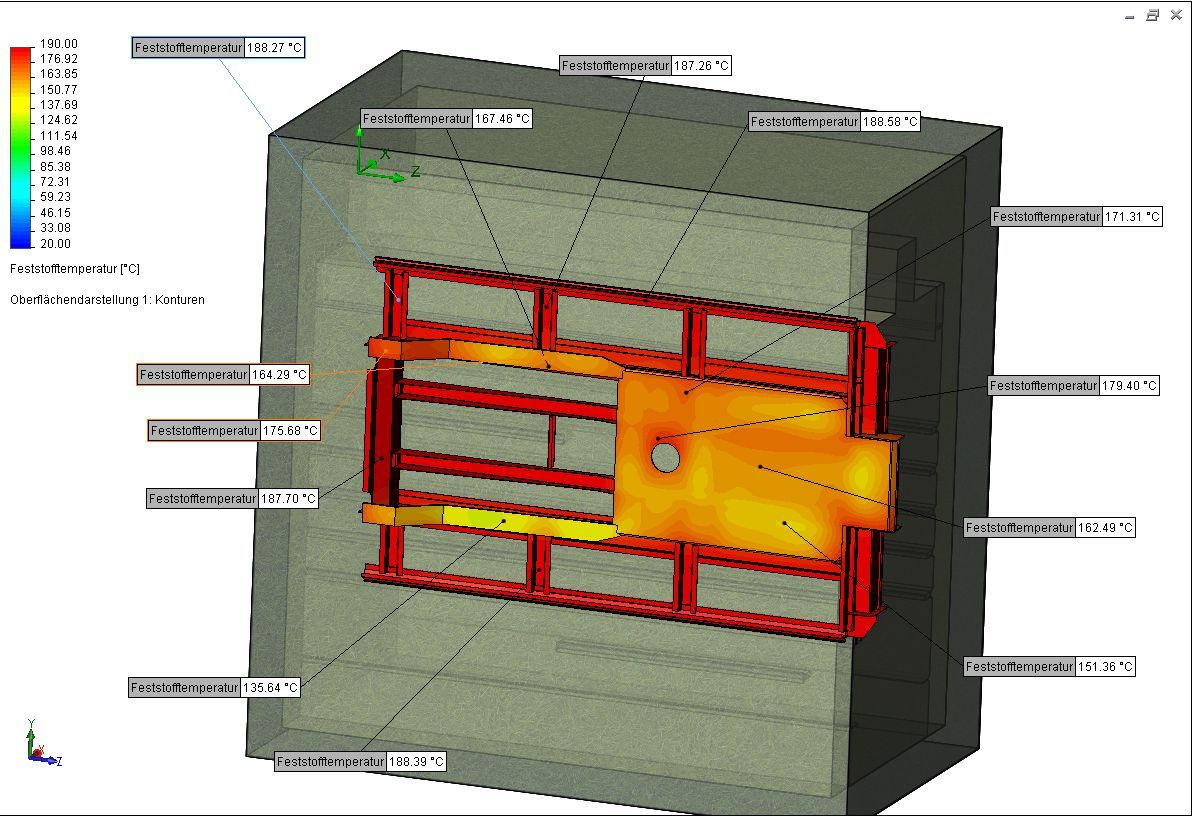

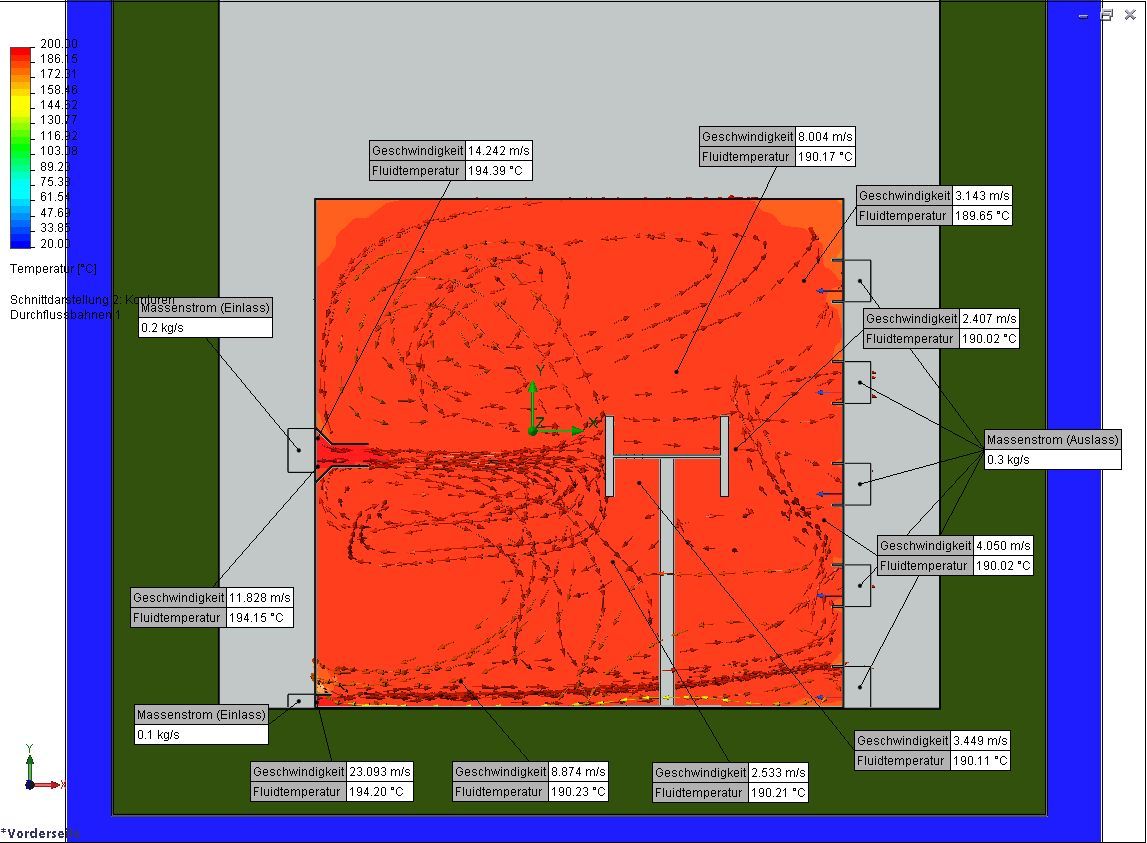

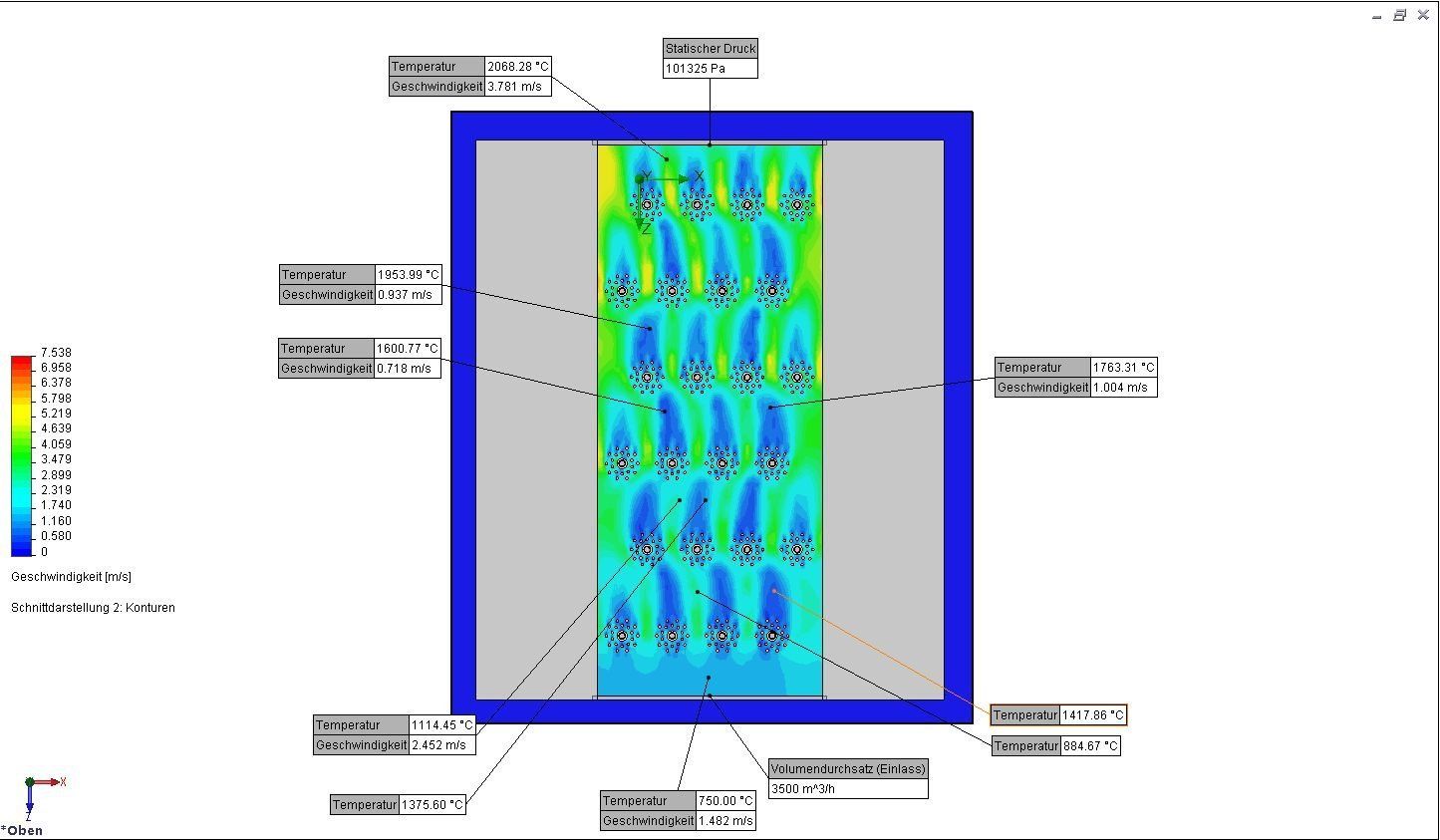

Thermal simulation and flow simulation

Thermal and flow simulations from ENA GmbH – maximizing efficiency, improving processes

ENA GmbH is your competent partner for thermal and fluid flow simulations, both static and transient. With sound engineering experience and state-of-the-art simulation software, we support companies in the development, optimization, and validation of industrial furnaces, vacuum furnaces, continuous furnaces, and heat treatment plants.

Our transient and static thermal simulations provide precise data on temperature development, energy distribution and flow guidance – ideal for complex industrial processes with high demands on process safety, energy efficiency and product quality.

Why thermal and flow simulations?

Through the targeted application of thermal and fluid dynamics simulation, you gain in-depth insights into your thermal processes – even before a component is manufactured or a system is built. This reduces development time, avoids costly design errors, and enables targeted optimizations during operation.

Our simulation services cover, among other things, the following aspects:

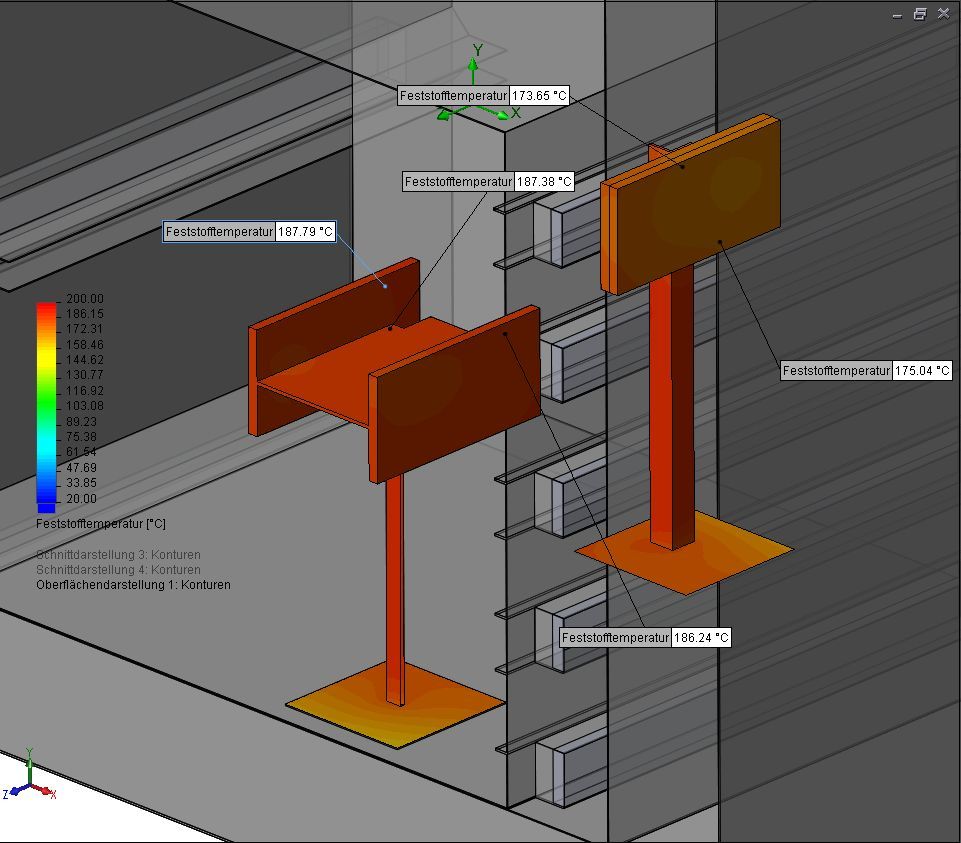

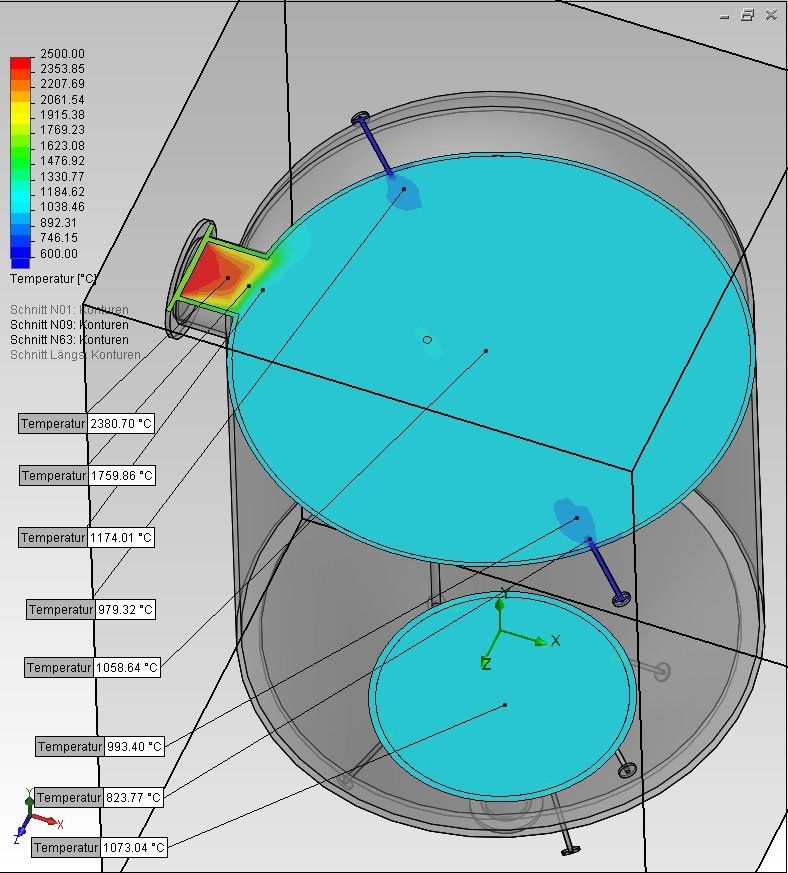

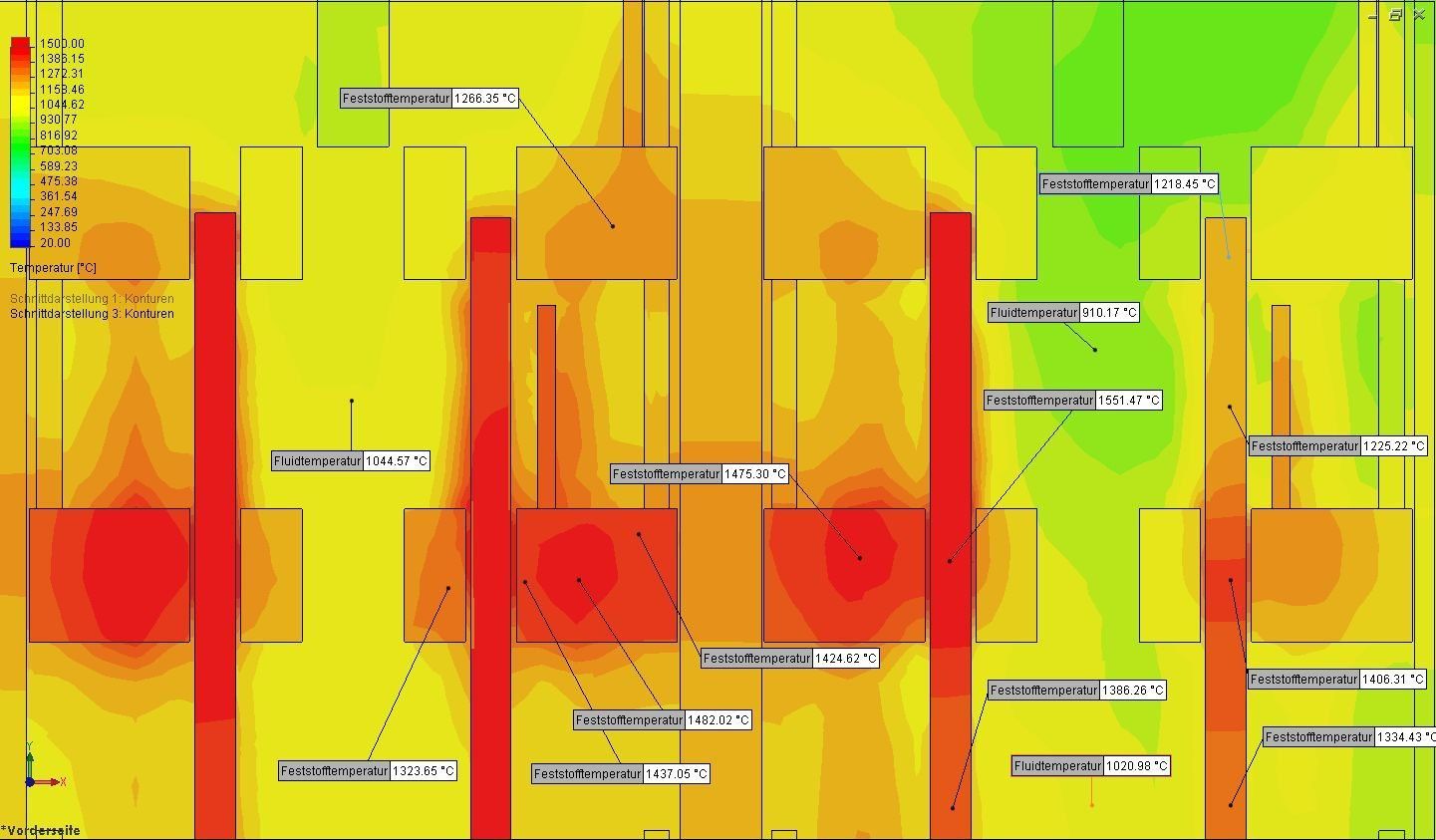

Temperature distributions in components and furnace systems

Identification of hot spots and temperature gradients

Analysis of heating and cooling profiles (transient)

Flow distribution of gases and liquids in complex geometries

Heat transfer coefficients for dimensioning heating elements or cooling zones

Your benefits from our thermal and fluid dynamics simulations:

✅ Technological process reliability

By accurately modeling and simulating real operating conditions, critical process parameters can be identified and validated early on.

✅ Precise heating and cooling time calculations

Transient simulations can be used to optimize thermal cycle times – a crucial factor for energy savings and productivity.

✅ Loss analysis and energy saving

We identify heat losses and propose targeted measures to reduce waste heat and increase efficiency.

✅ Even temperature distribution

Our simulations ensure homogeneous heating of components in vacuum furnaces, industrial furnaces or continuous furnaces – essential for reproducible quality.

✅ Improved flow conditions

Through CFD (Computational Fluid Dynamics) analysis, we optimize the flow of process gases or cooling media and thus improve heat transfer.

Technical expertise in transient simulation & flow simulation

Whether static or transient, our simulations offer solutions for a wide variety of thermal challenges – from the design of individual heating zones to the control of complex temperature profiles and the design of efficient air and gas supply systems.

Typical application areas of our simulation projects include:

Vacuum heat treatment

Soldering and sintering processes

Protective gas processes

Thermal degreasing

Kiln applications

Indirect heating with circulating air

Get personalized advice

Our experienced engineers will guide you from the initial concept to the validated simulation and support you in implementing concrete optimization measures. Thermal and fluid dynamics simulations are now indispensable tools for increasing the energy efficiency, product quality, and operational reliability of your systems.

📞 Get in touch now and request a simulation consultation – for a precise and economical design of your industrial processes!