ENA Dome Ovens / Dome Ovens Industrial Ovens

Dome ovens / High-temperature ovens

Flexible configuration for versatile heat treatment processes with bell furnaces

ENA bell furnaces – Flexible industrial furnaces for demanding heat treatment processes

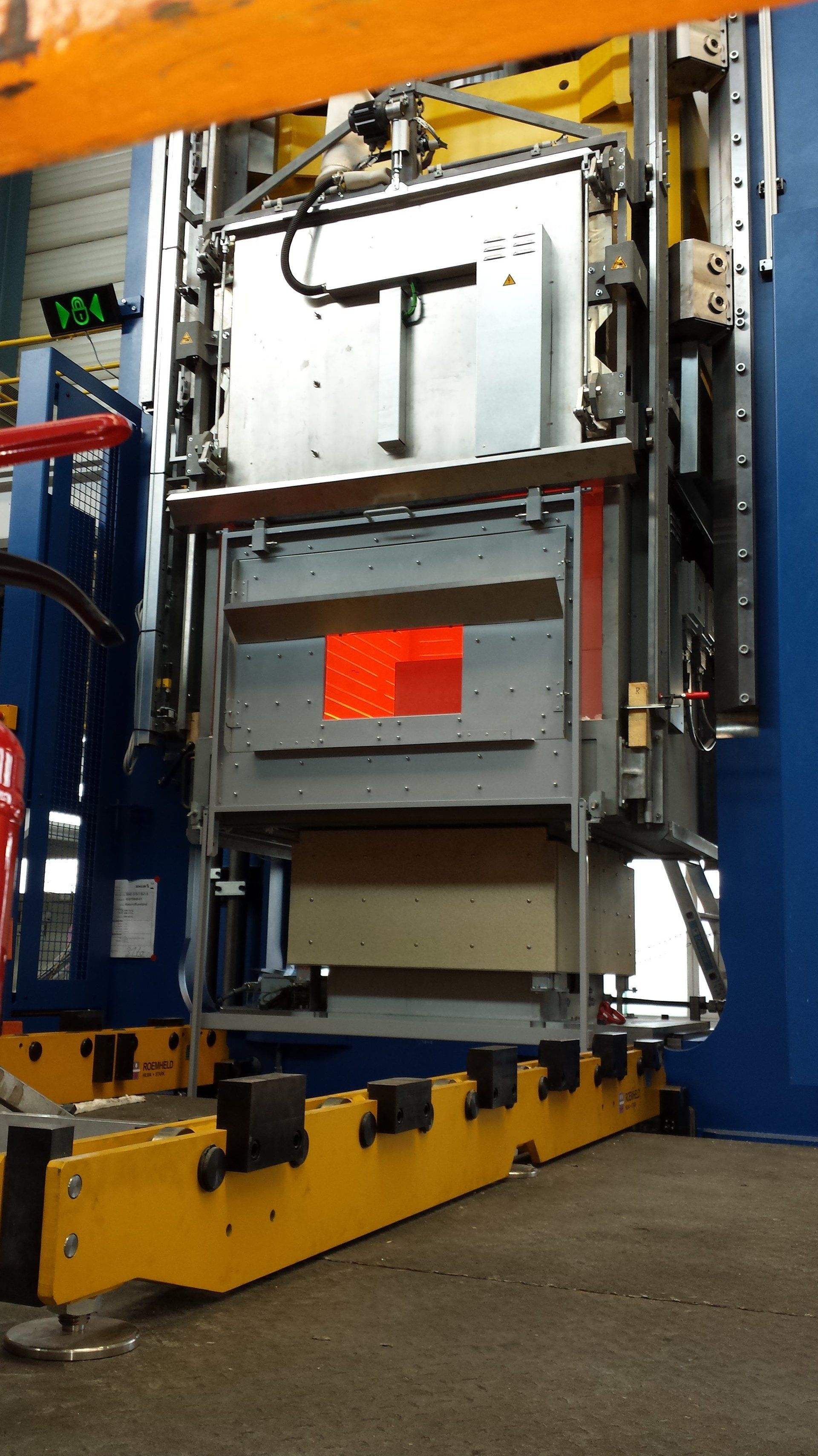

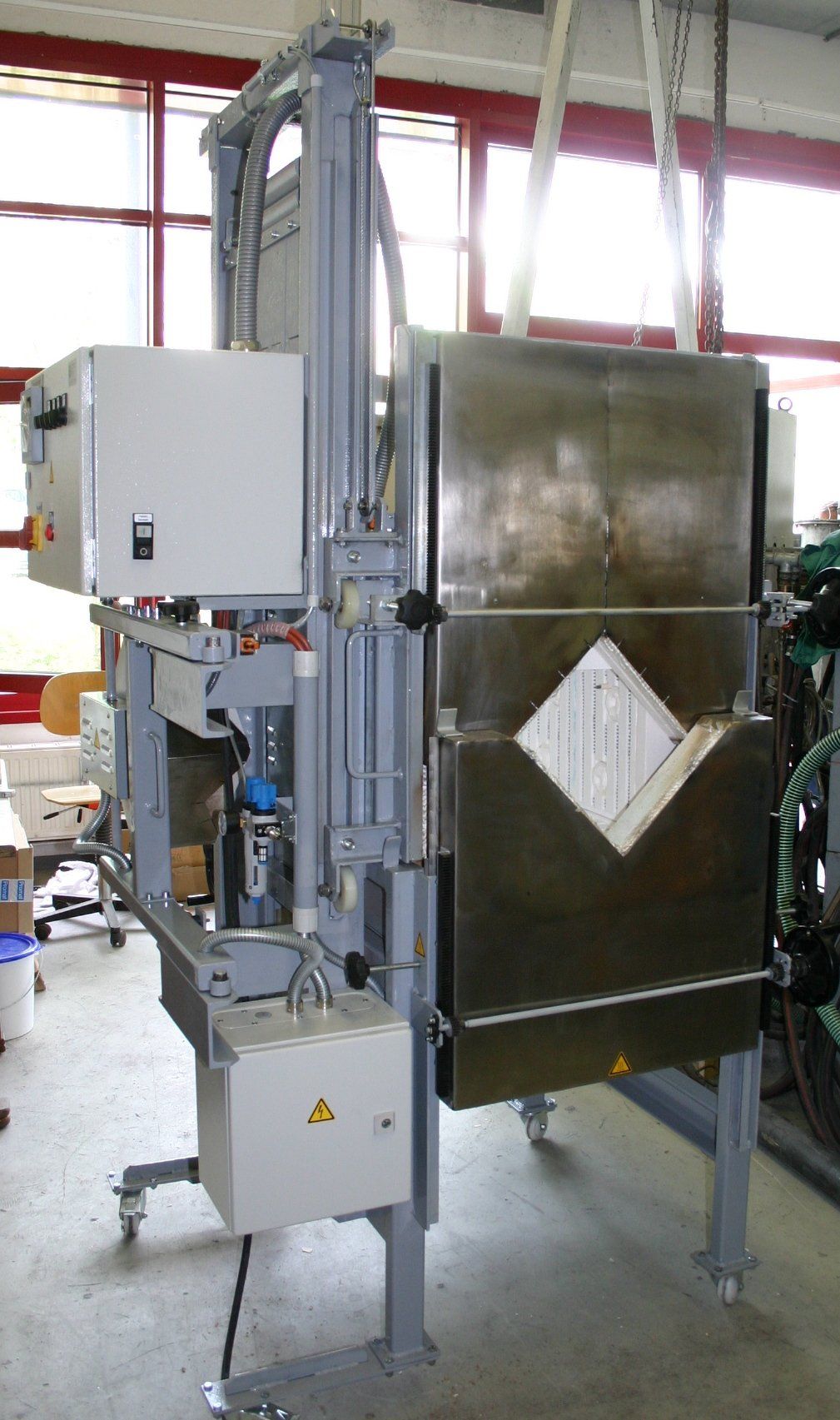

Bell-type furnaces are among the most versatile and adaptable industrial furnaces, especially when it comes to variable loading concepts and individual process requirements. A typical feature of a bell-type furnace is the flexible loading option – depending on the design, the furnace chamber can either be closed from above with a retractable hood, or the furnace floor itself can be raised or lowered. This modular design allows for optimal adaptation to workpiece geometries, cycle times, and automation concepts.

Different opening mechanisms – tailored to your process

Our bell furnace systems are available with various opening mechanisms, depending on the desired automation, accessibility and design:

Pneumatic hood opening: For automated processes with minimal operator intervention

Mechanical hood lifting: Either the hood moves upwards or the oven floor moves vertically – ideal for tall ovens

loads or precise positioning

This flexibility makes our bell furnaces the ideal solution for applications where reproducible temperature control and fast loading and unloading are required – e.g., for annealing, sintering, preheating or heat relaxation.

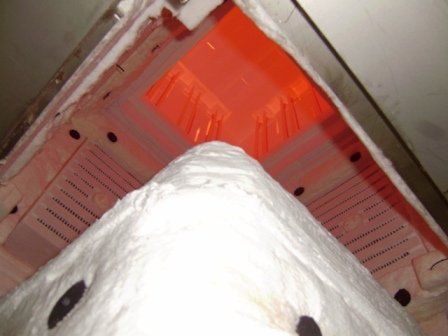

High-temperature dome furnaces – Powerful performance across all temperature ranges.

Our hood-type furnaces for industrial applications cover a wide temperature range:

Standard operation: 150 °C to 1,450 °C – suitable for most heat treatment processes in air or controlled atmospheres

Special furnaces: 1,550 °C to 1,850 °C – for high-temperature applications under protective gas, e.g. in sintering technology, ceramic processing or powder metallurgy

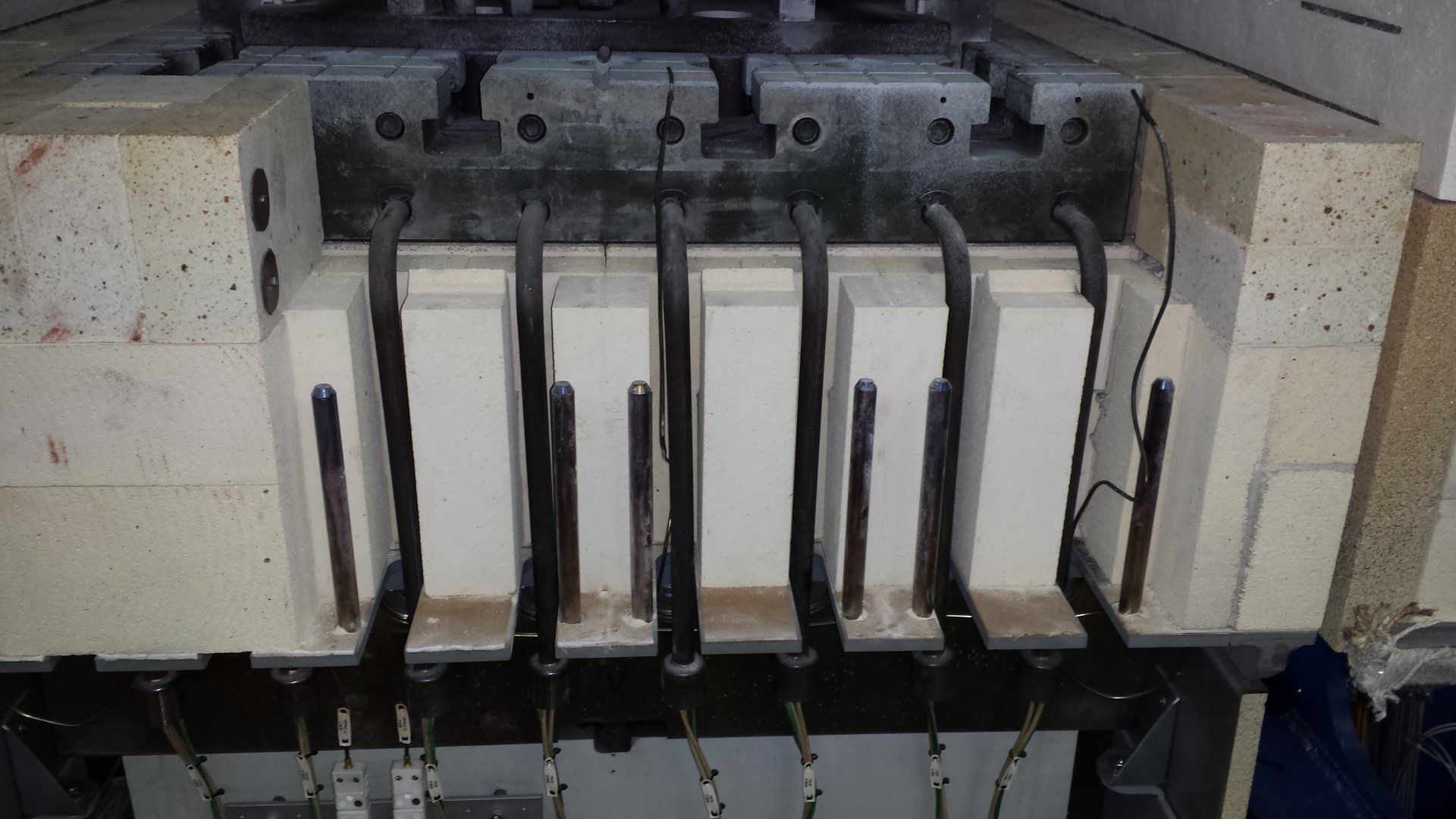

Depending on requirements, our hood furnaces can be equipped with additional insulation, multi-zone heating, or integrated cooling. They can also be combined with continuous or vacuum furnaces – for example, in a multi-stage heat treatment line.

Your advantages with a hood oven from ENA

Our bell-type industrial furnaces are available in a wide range of sizes, performance levels, and automation levels. Depending on the application, you will receive:

Flexible loading options

Compact design for space-saving integration

High temperature accuracy through multi-zone control

Protective gas capability for sensitive materials

Durable construction thanks to robust materials and modern insulation technology

Tailor-made industrial furnace technology for your manufacturing

Every hood furnace we build is the result of close collaboration with the customer. Based on your production processes, workpieces, and temperature requirements, we develop a perfectly tailored solution – whether as a standalone furnace or integrated into a fully automated heat treatment system.

Our bell-shaped furnaces can also be easily integrated into existing manufacturing processes, even in combination with continuous furnaces, paternoster furnaces or vacuum furnaces.

Technical specifications at a glance

Temperature ranges: 150 °C – 1,450 °C (up to 1,850 °C on request)

Atmospheres: air, protective gas, vacuum (optional)

Types of construction: Top-loading, bottom-lifting, mechanical or pneumatic

Options: Automated loading, energy optimization, process data acquisition

Industries: Metal processing, foundry, glass, ceramics, aerospace, automotive

Request a quote for a suitable hood-type oven now!

Are you looking for a reliable, efficient, and precisely customizable solution for your heat treatment needs? Then let us advise you. We develop and manufacture your individual bell furnace, tailored to your specific requirements in industrial heat treatment.

📞 Contact us today or request your personal offer directly!