ENA PATERNOST OVEN / PATERNOST OVEN

Paternoster oven / Paternoster ovens - Applications

Efficient, space-saving heat treatment for continuous processes

ENA Paternoster Ovens – Continuous heat treatment in the smallest space

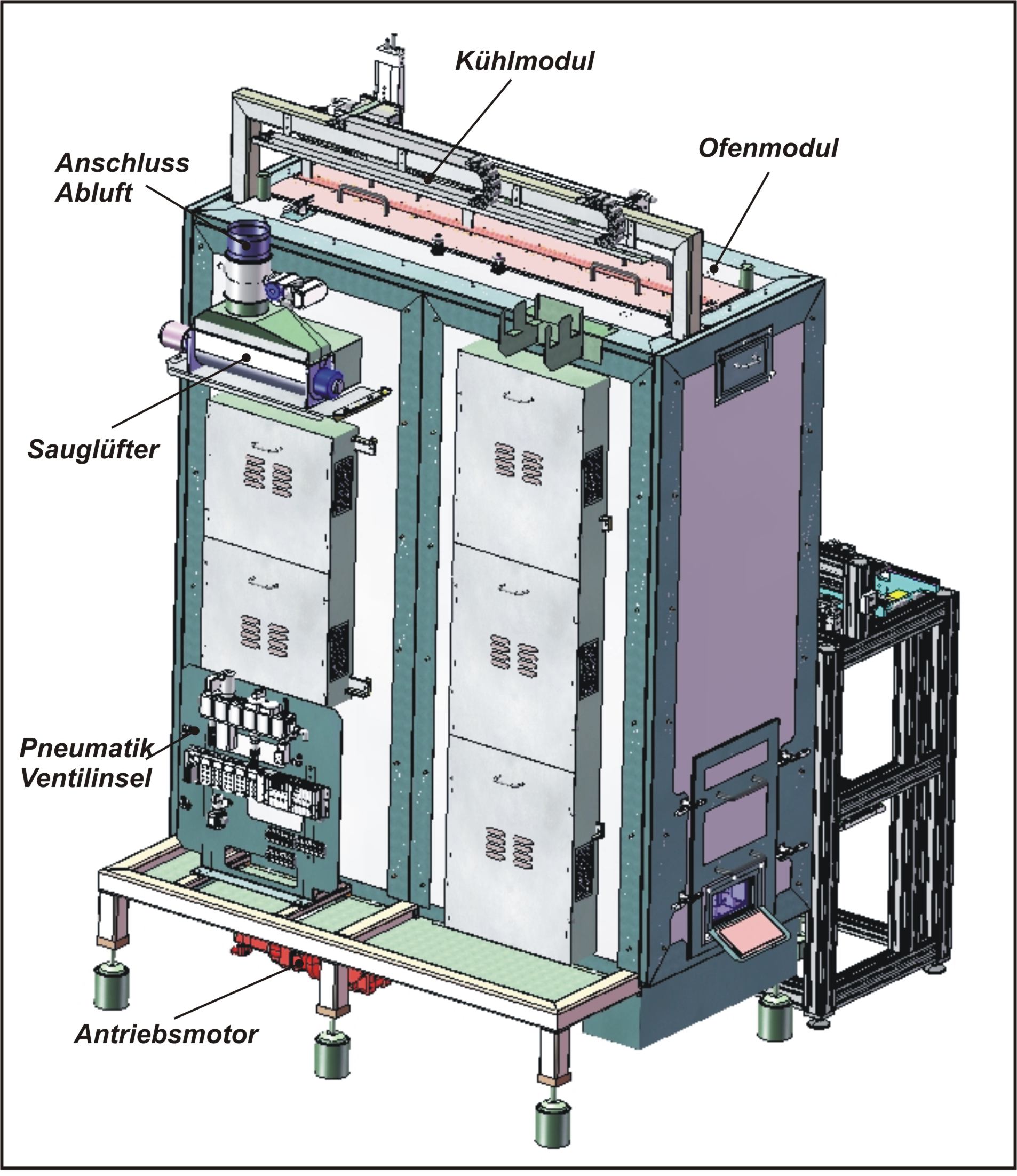

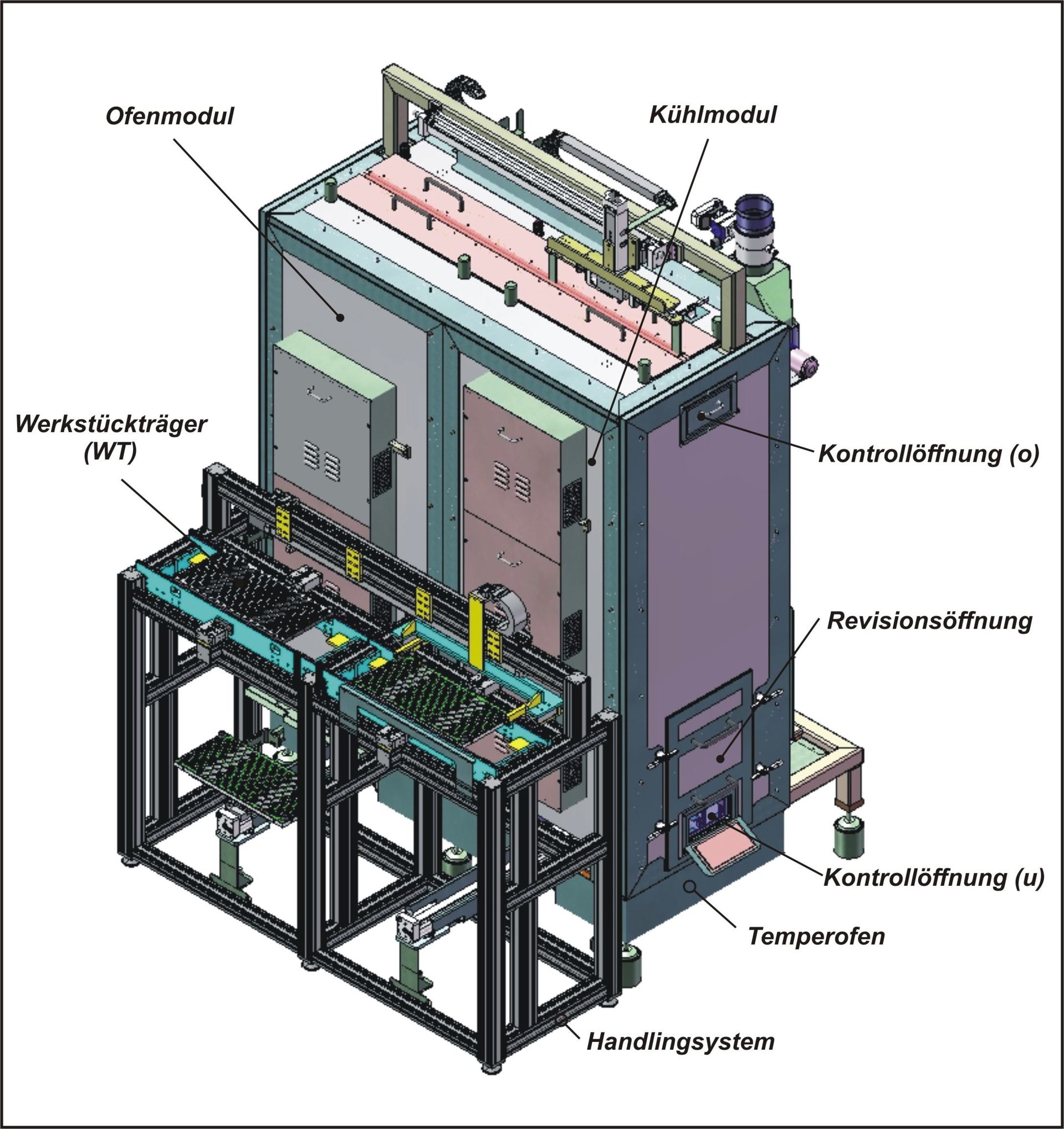

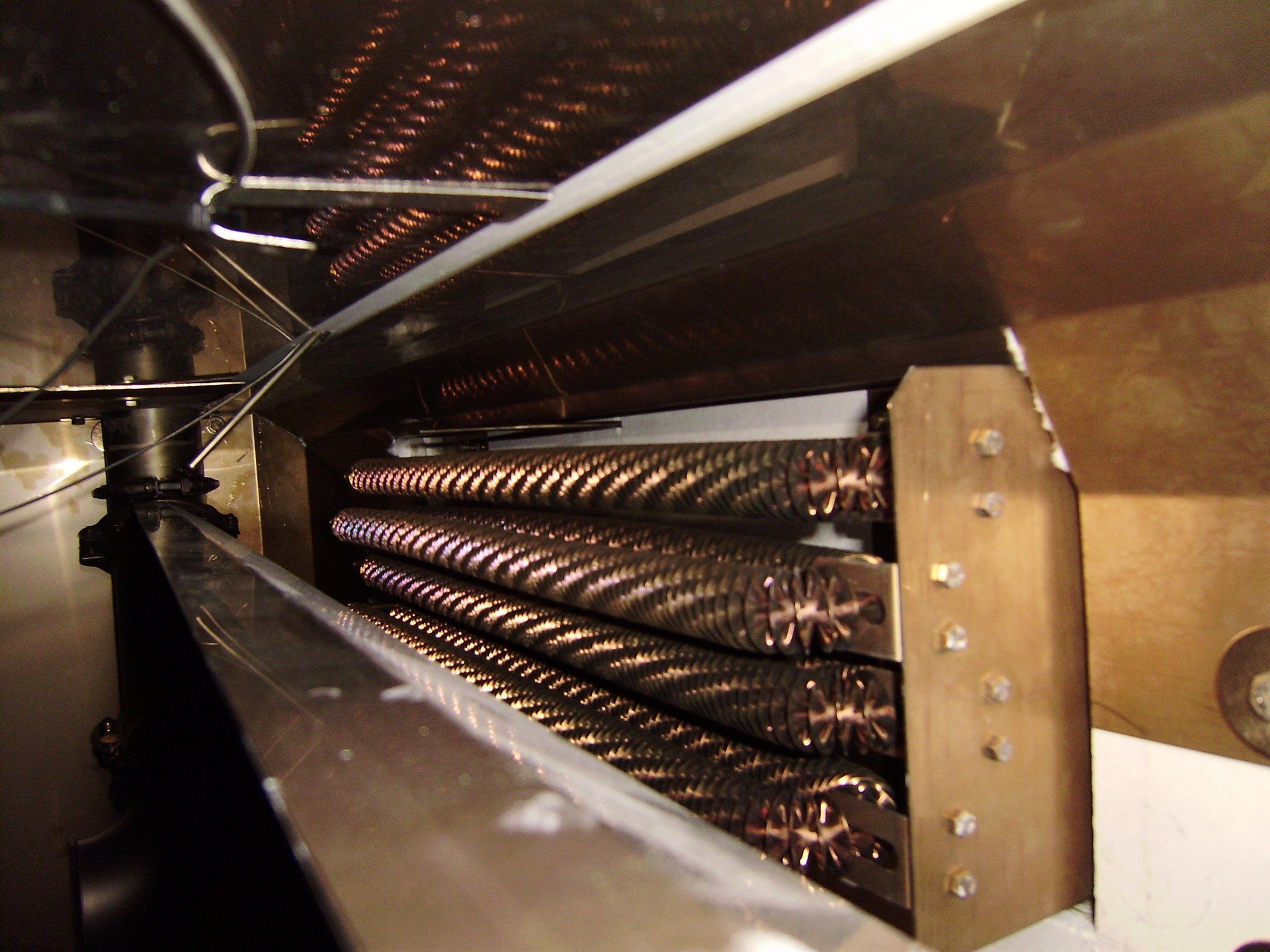

ENA's paternoster furnaces are specially designed industrial furnaces used for continuous, reliable, and space-saving heat treatments. These state-of-the-art heat treatment systems are particularly suitable for applications requiring a continuous material flow, uniform temperature distribution, and a compact design.

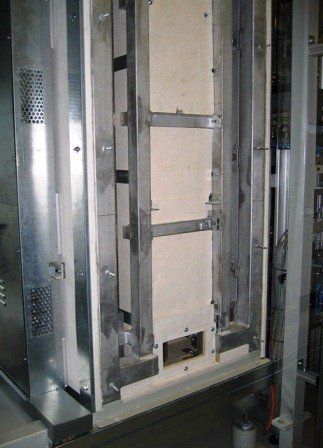

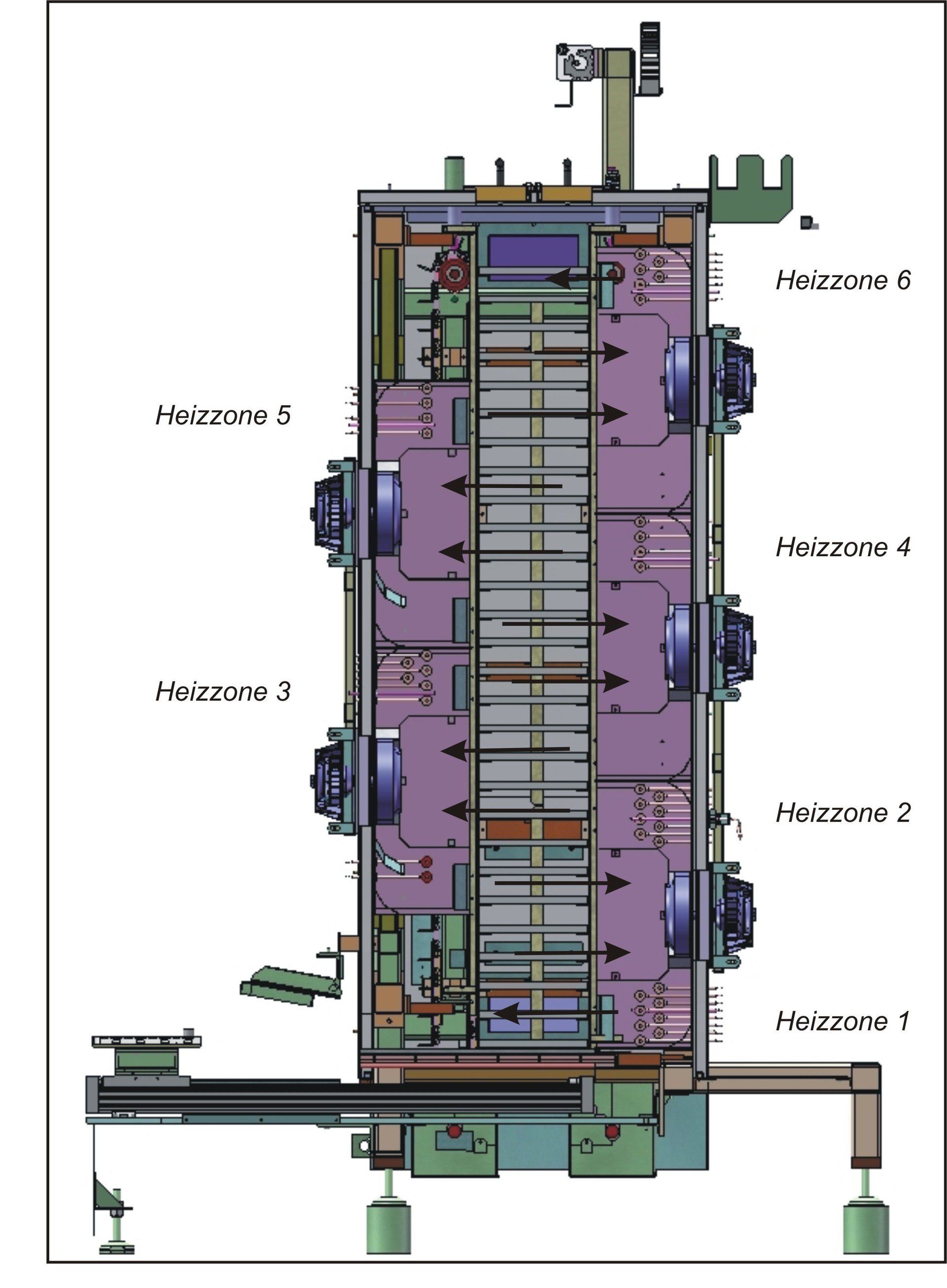

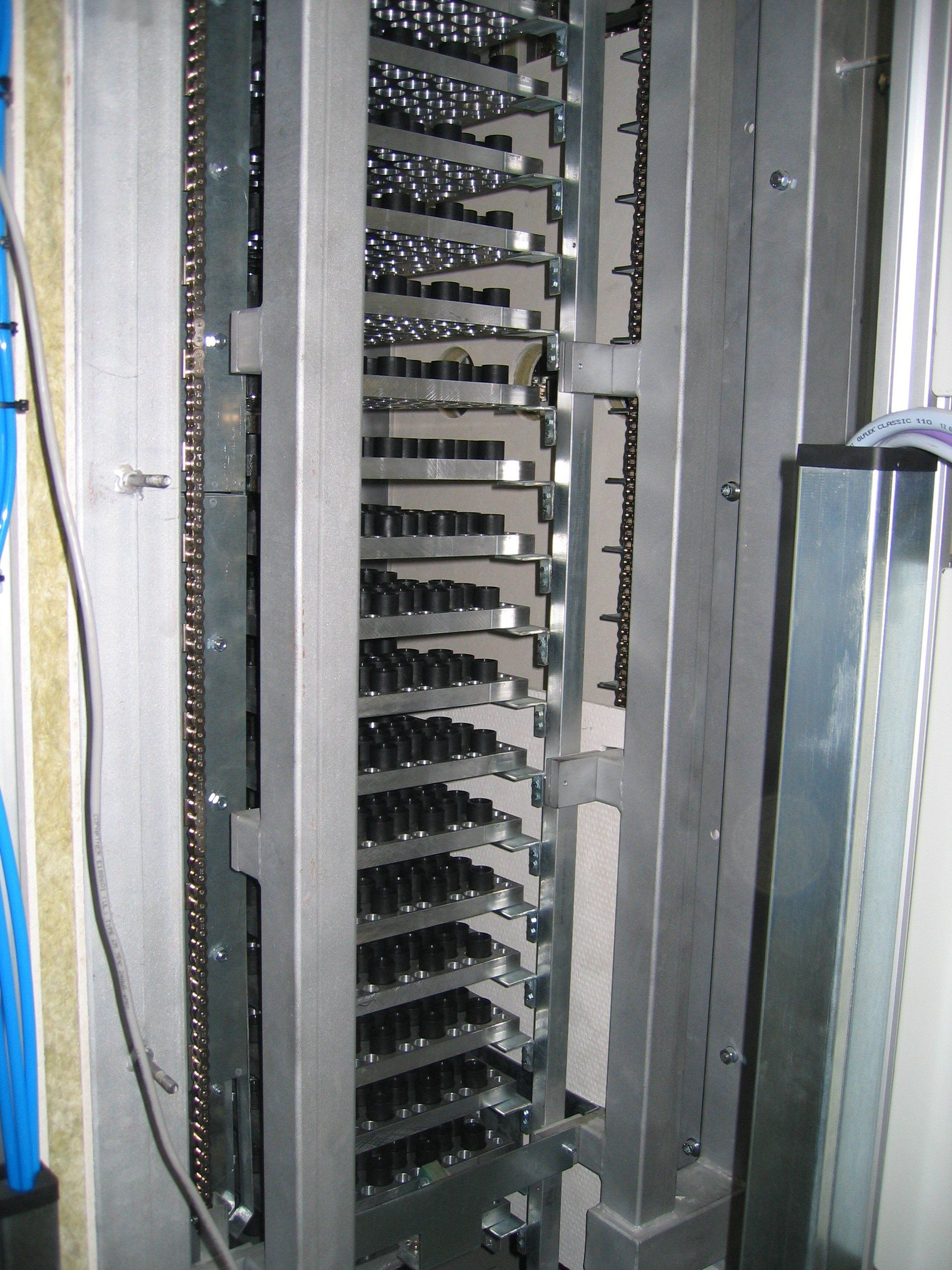

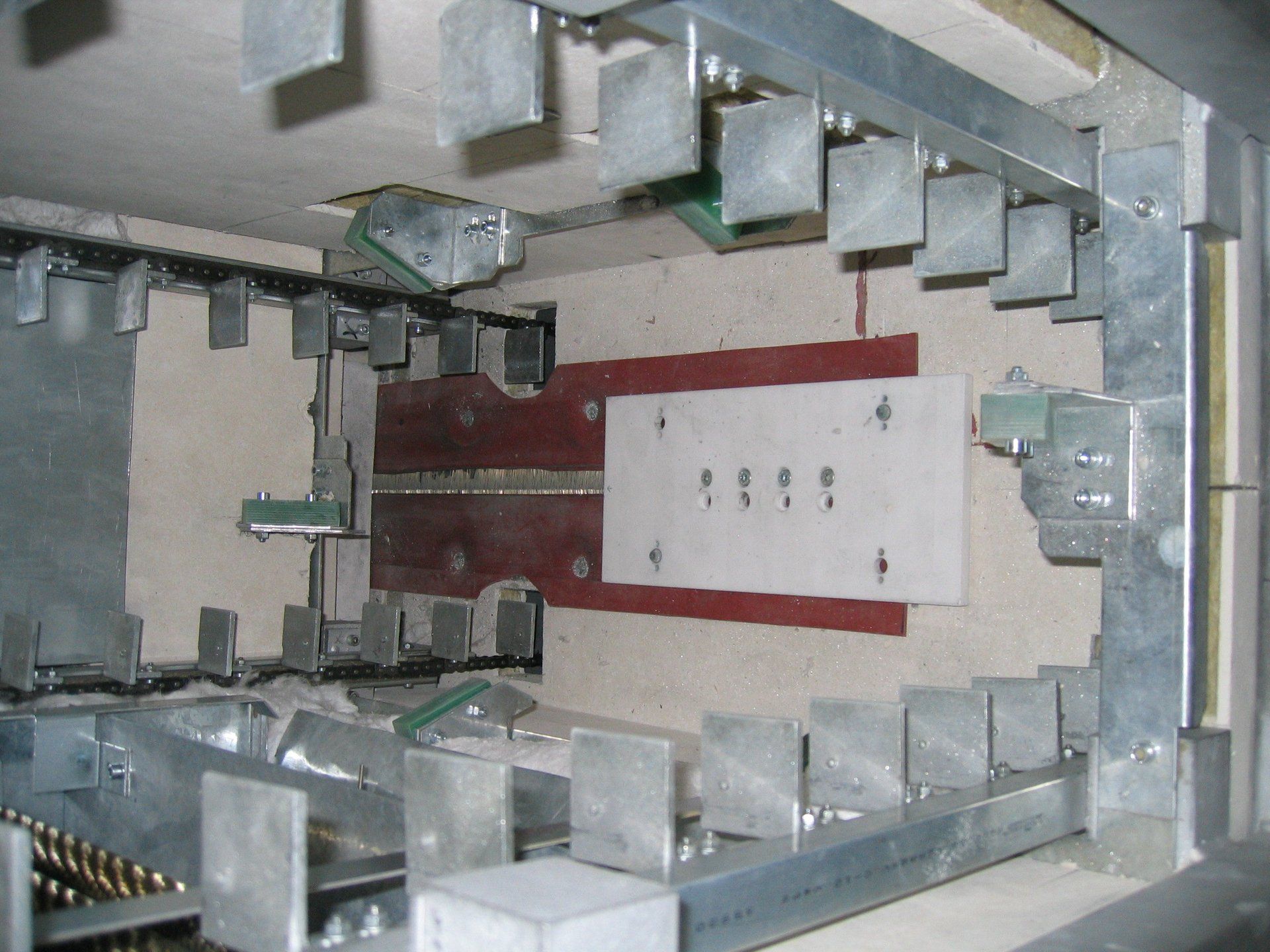

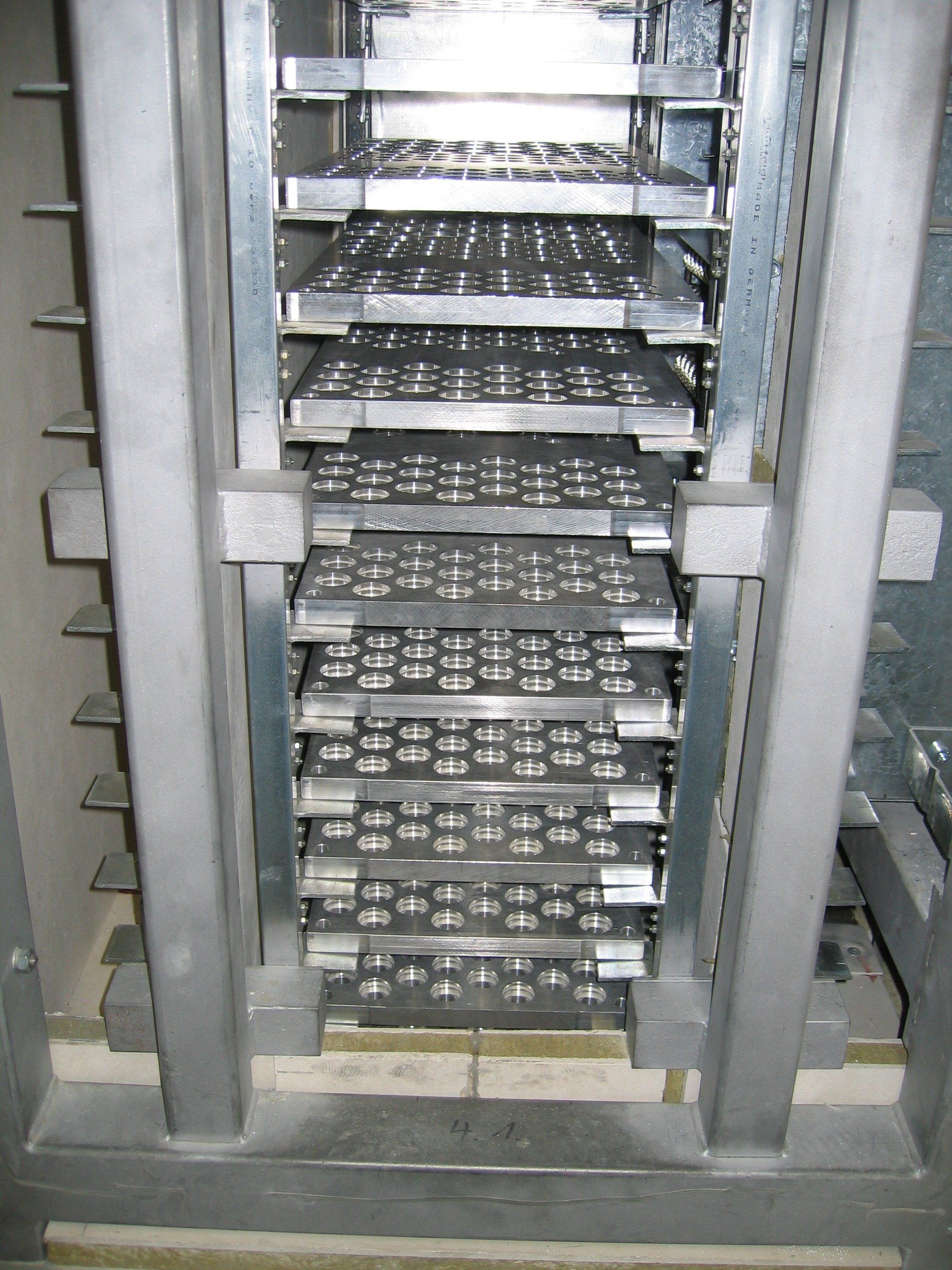

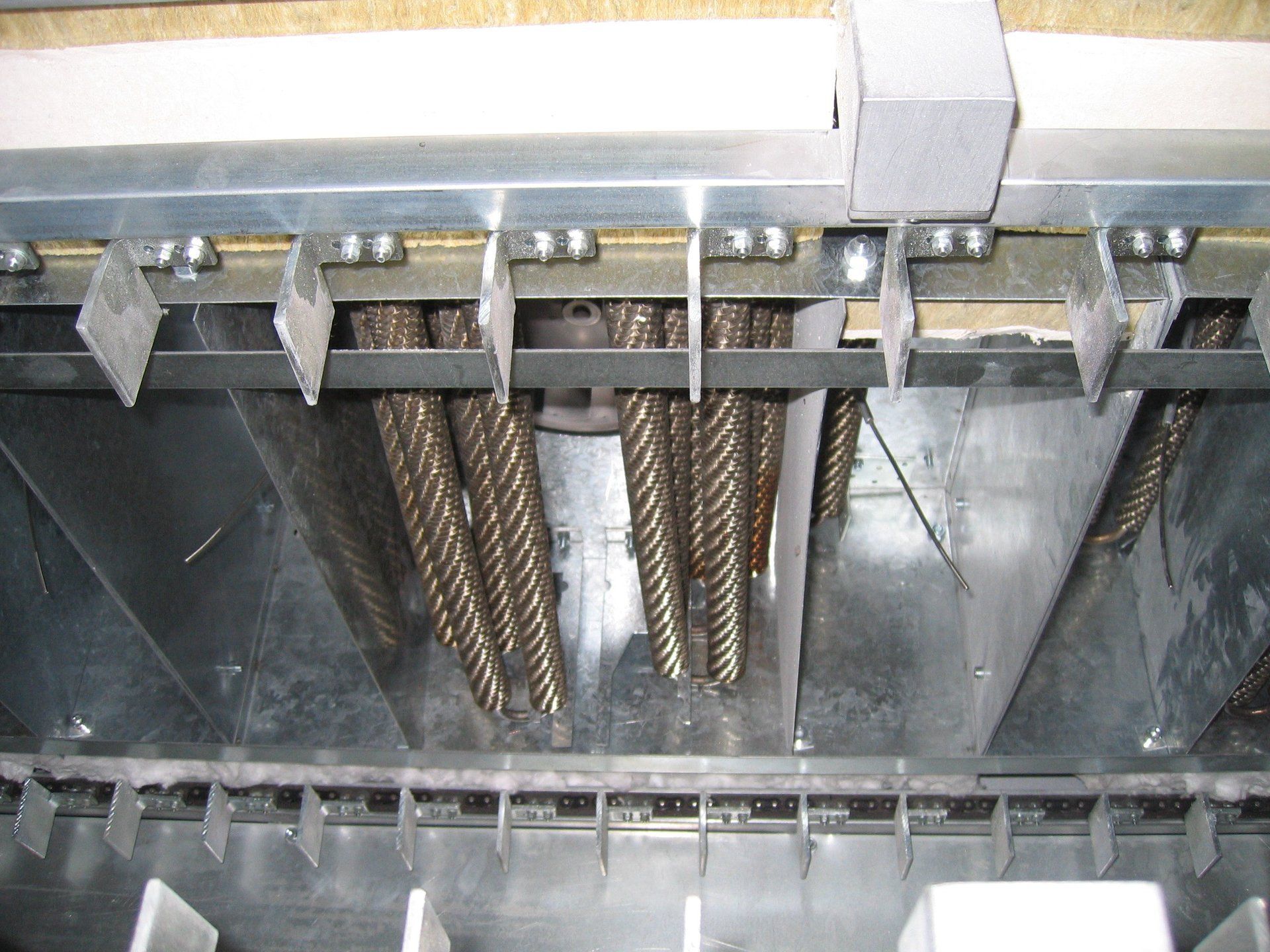

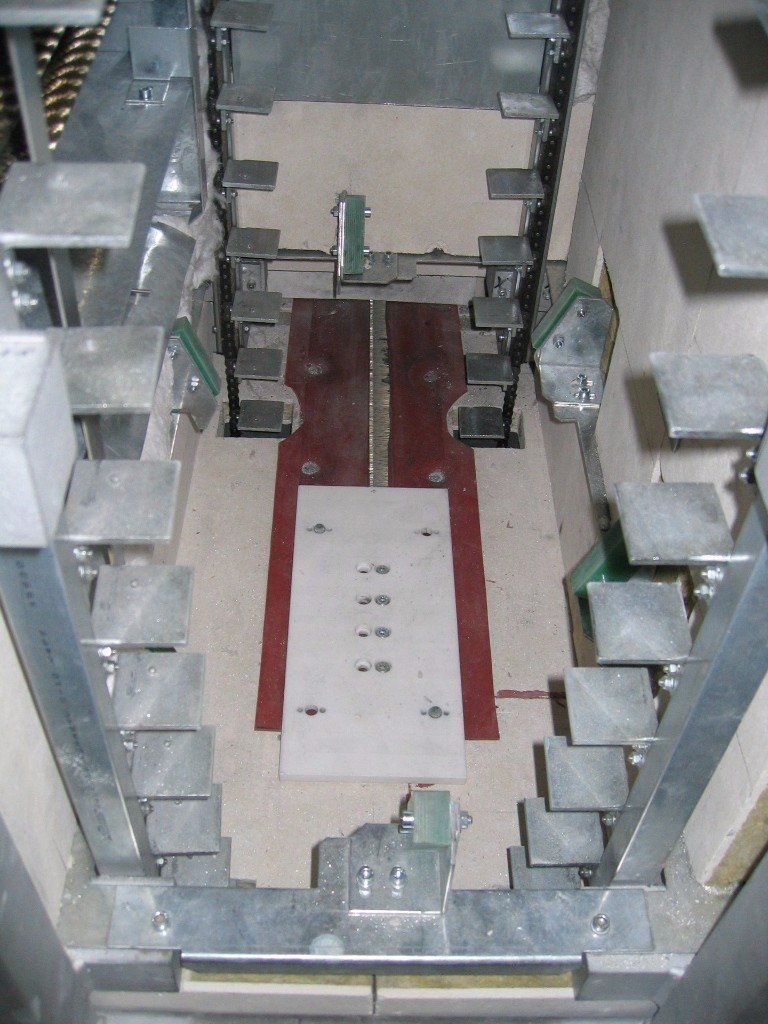

In the application shown, batch carriers are guided vertically through several defined heating and cooling zones via a circulating conveyor system. This ensures homogeneous and reproducible heat treatment of the workpieces throughout the entire process – comparable to high-quality continuous furnaces, but with a significantly reduced footprint.

Ideal for industrial processes with high demands on efficiency and space saving.

Paternoster furnaces combine the advantages of a continuous flow principle with the compact vertical structure of a paternoster system. Compared to conventional industrial furnaces or horizontally oriented continuous furnaces, they offer significant advantages in confined spaces – without compromising performance, temperature distribution, or process reliability.

This makes our paternoster furnace systems the ideal solution for industries such as metal processing, automotive, electrical engineering or plastics engineering, where precise temperature control, high repeatability and automated material flow are essential.

Automated loading and unloading for maximum process control

The fully automated loading and unloading of our paternoster ovens ensures a constant production flow and reduces manual intervention to a minimum. This not only increases productivity but also process reliability, reduces potential sources of error, and lowers operating costs in the long term.

Our systems can be seamlessly integrated into existing production lines and can be linked to both higher-level control systems (e.g. SCADA, MES) and robotics solutions.

Technical specifications at a glance

Our paternoster ovens impress with the following performance features:

Temperature range: up to 250 °C (higher temperatures on request)

Vertical batch handling: for uniform heating and cooling

Design: individually adaptable to workpiece size, process times and cycle times

Oven type: continuous industrial oven with high energy efficiency

Compact footprint: optimal space utilization

Integration: possible with pre- and post-treatment stations or other continuous ovens

Special solutions with specific process gases, atmospheres or additional heat treatment technology are also possible.

ENA's customized industrial furnace technology

Each of our paternoster ovens is developed and manufactured in close consultation with the customer – precisely tailored to their specific requirements. Our engineering team takes into account all relevant factors such as production capacity, material, temperature profile, and cycle times.

Whether as a standalone system, as part of a complex heat treatment line or in combination with a classic continuous furnace – ENA delivers robust and maintenance-friendly solutions for industrial heat treatment.

Your advantages at a glance:

Space-saving design with high throughput capacity

Continuous process control for series production

Uniform temperature control of the workpieces

Fully automated loading and unloading for maximum efficiency

Individual adaptation to your production environment

Long-term operational reliability through low-maintenance design

Request a quote for the perfect paternoster oven now!

Are you looking for a powerful and compact solution for your heat treatment needs? Then an ENA paternoster furnace is exactly what you need. Our team will be happy to advise you on continuous furnaces, industrial furnaces, and all other heat treatment systems.

📞 Contact us now – we'll create a customized offer for you!