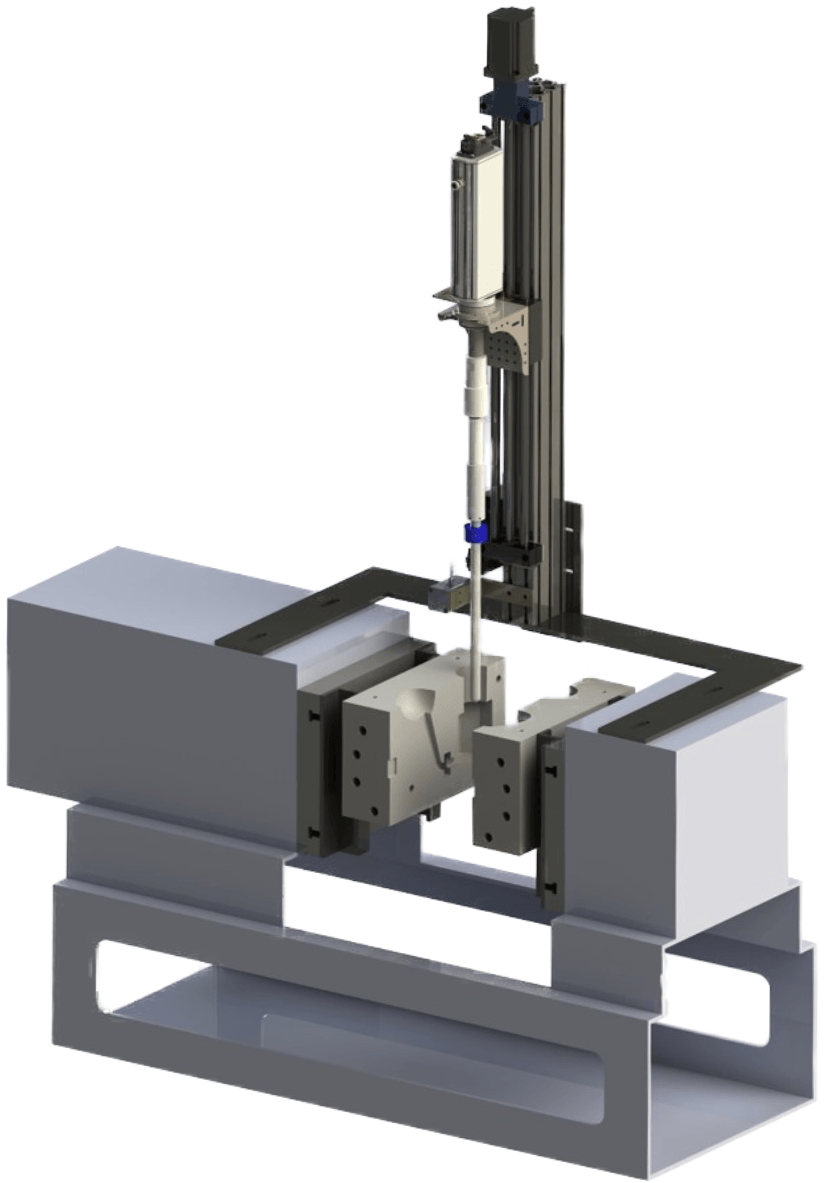

Equipment / systems for the ultrasonic treatment of light metal melts

Ultrasonic treatment of light metal melts

Ultrasonic treatment for improved casting quality – High-quality metal components for demanding applications

The casting process is crucial for the quality of metallic components and significantly influences their durability and resilience. With increasing demands in mechanical engineering, the automotive industry, and aerospace, the need for advanced manufacturing technologies is growing.

Aluminium plays a key role in this: its combination of excellent mechanical properties and low weight makes it one of the most important lightweight materials.

To optimize aluminum components for highly stressed applications, we employ an innovative ultrasonic treatment. This technology alters the metal's microstructure and significantly improves crucial mechanical properties.

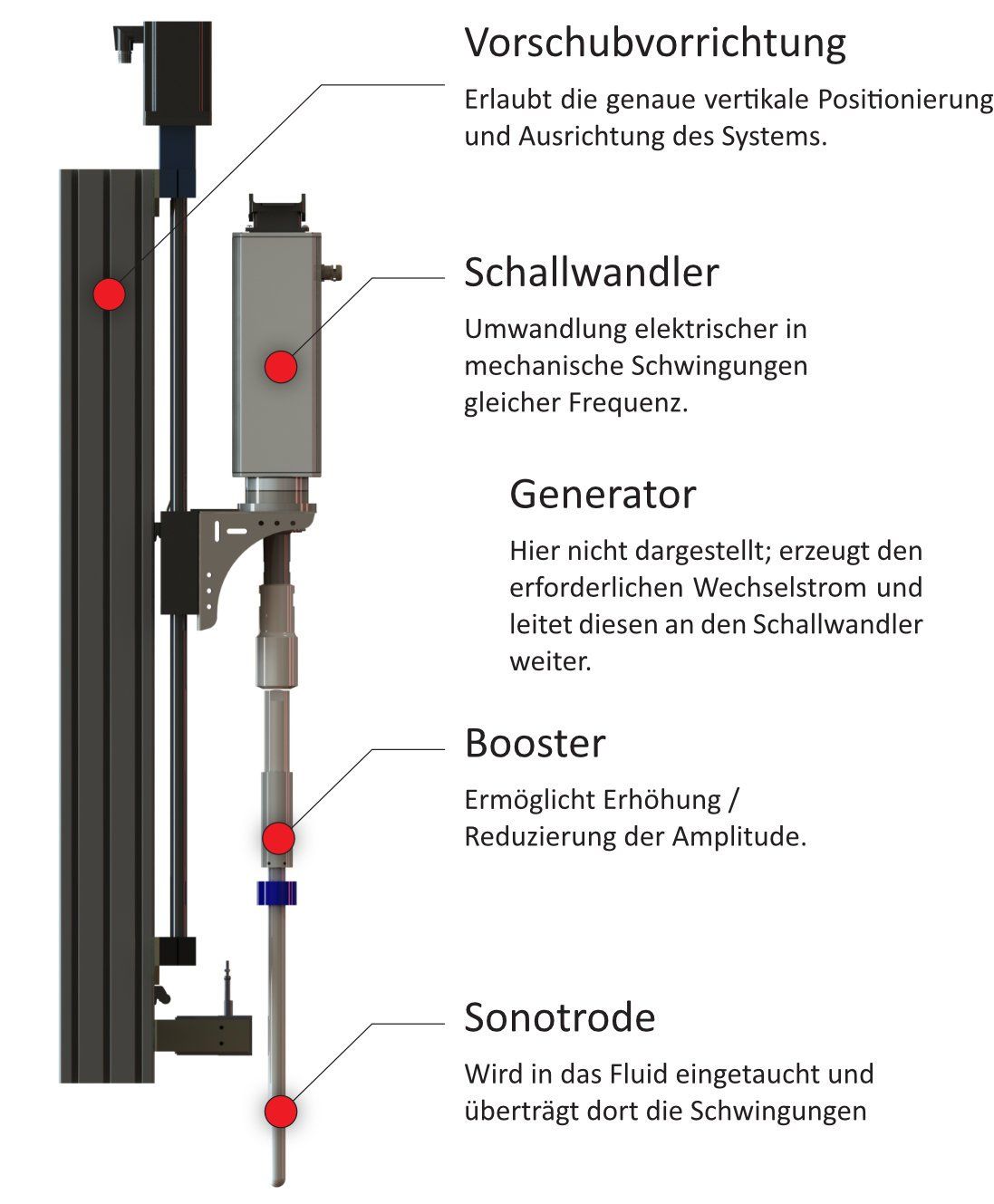

How the ultrasound system works

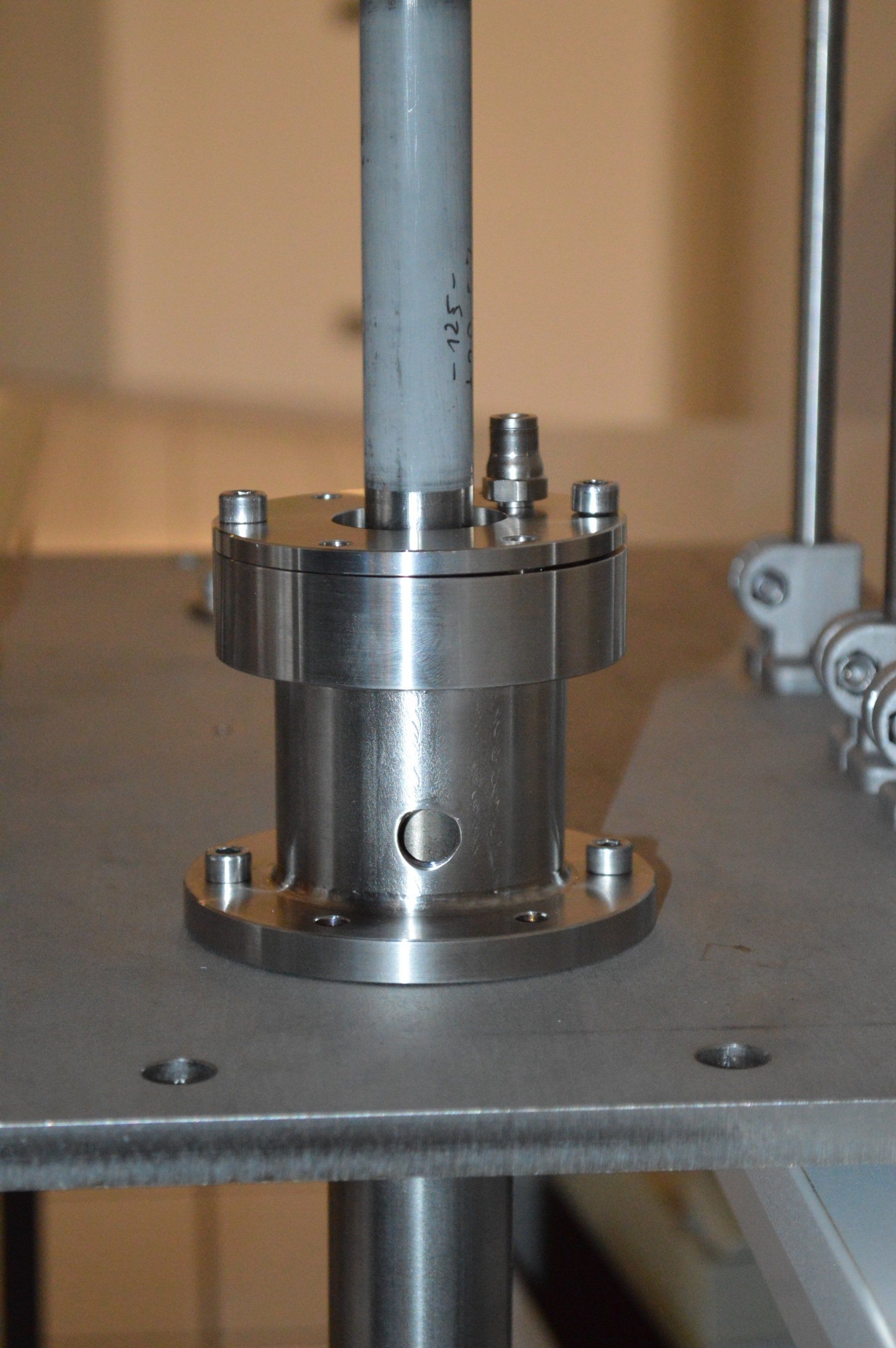

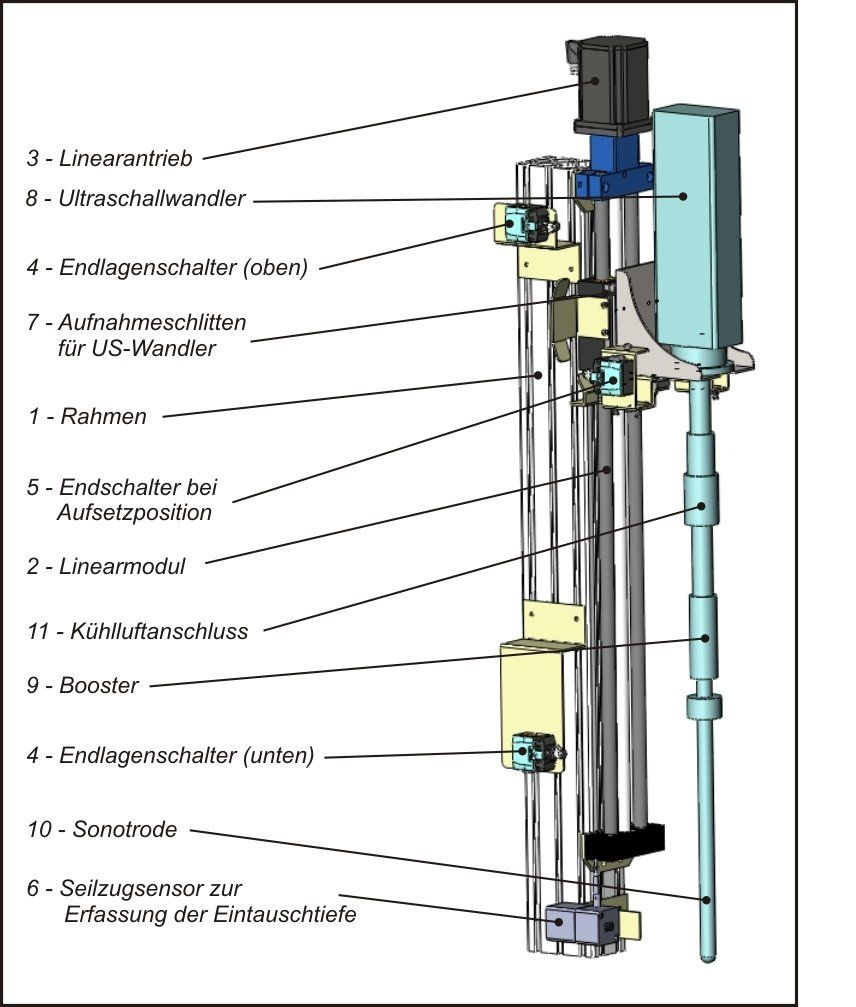

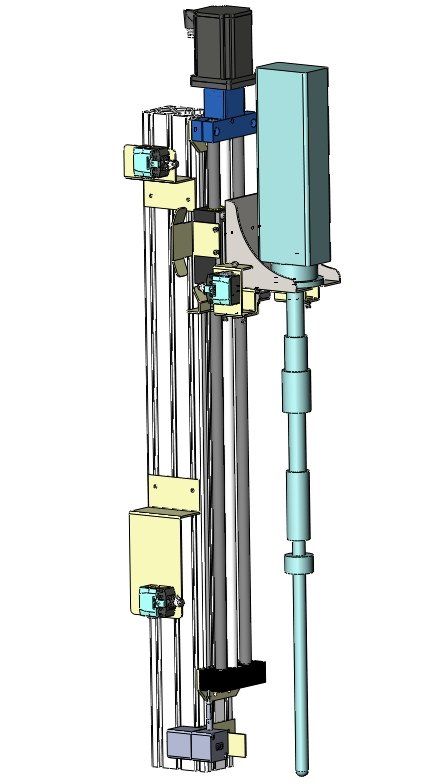

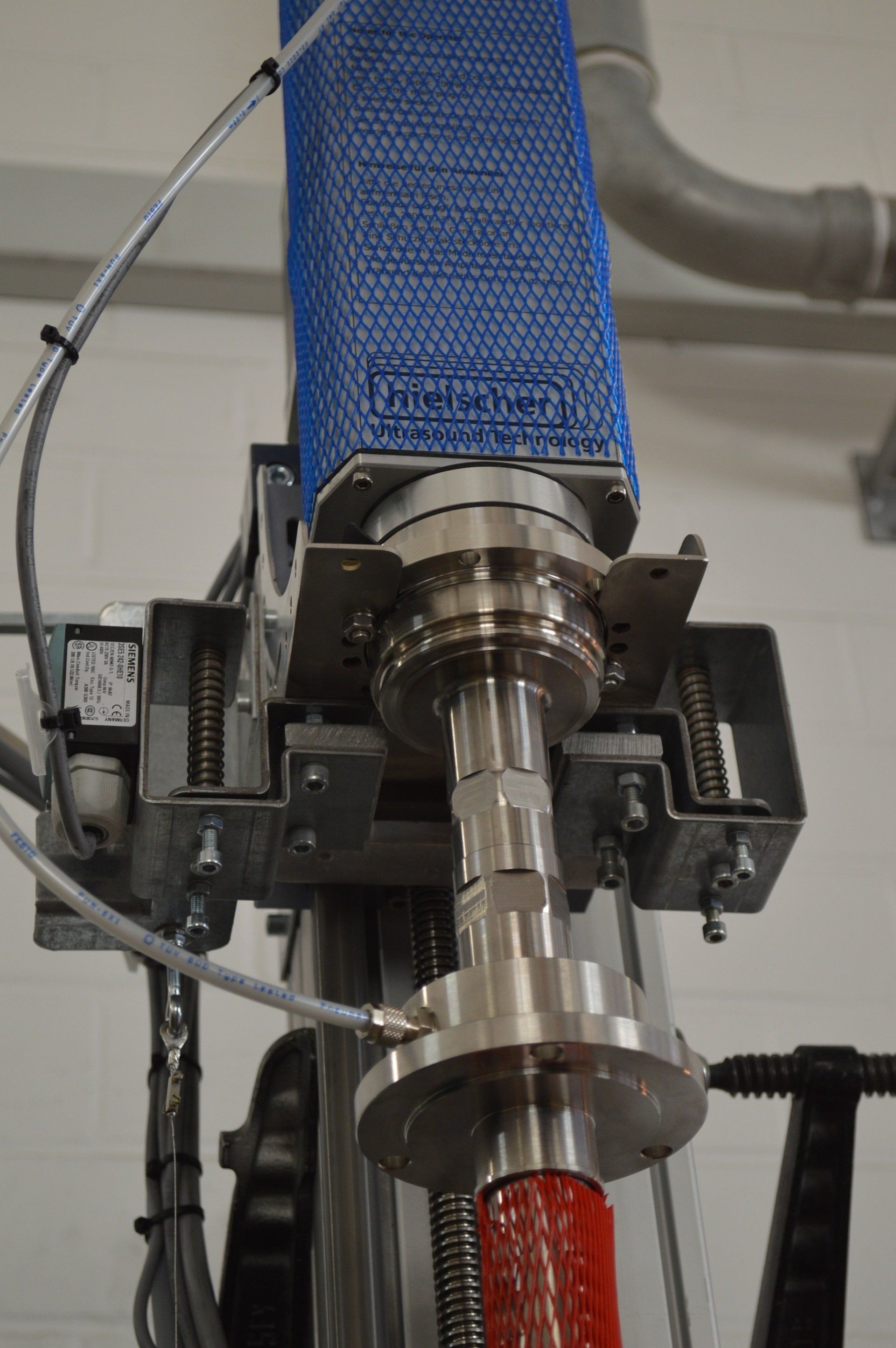

The ultrasound system consists of four main components:

- Generator – Generates alternating current and transmits it to the transducer

- Sound transducer – Converts electrical oscillations into mechanical vibrations

- Booster (optional) – Regulates the amplitude of the vibrations

- Sonotrode – Transmits mechanical vibrations into the melt and generates massive pressure fluctuations

These pressure fluctuations change the microstructure from dendritic to globular, thereby significantly improving the mechanical properties of the material.

Advantages of ultrasonic treatment of aluminium

- Fine-grained structure – Improved mechanical properties

- Increased strength and ductility – Higher load-bearing capacity of the components

- Optimized casting quality – reduced porosity and more homogeneous microstructure

- Improved process control – enhanced reproducibility and material properties

Ultrasonic treatment of aluminium offers a pioneering solution for increasing the performance of this essential lightweight material – thus meeting the increasing demands of modern industries.

Contact us for customized solutions to improve your casting quality!