ENA Industrial Furnace Construction: Your manufacturer of custom-made industrial furnaces

ENA: Industrial furnaces tempering furnaces

Quality and precision in industrial furnace construction for over 30 years

ENA-Elektrotechnologien und Anlagenbau GmbH is your competent and reliable partner in industrial furnace construction. As an established manufacturer of industrial furnaces, we develop customized industrial furnaces and special thermal systems that meet the highest quality and efficiency requirements. Our solutions are used in demanding industries such as metal processing, the automotive industry, mechanical engineering, and aerospace.

Industrial furnace construction with experience and innovation

The Industrial furnace construction ENA Industrieofenbau GmbH has stood for the highest quality, technical expertise, and innovative solutions in the field of thermal processes for many years. As an experienced Industrial furnace construction manufacturer with seat in Stassfurt, Germany, we combine proven engineering know-how with modern manufacturing and control technologies.

Our industrial furnaces They are characterized by precise temperature control, high energy efficiency, and an exceptionally long service life. We place particular emphasis on sustainable concepts, low operating costs, and reliable process security – crucial factors for the economical operation of industrial furnace systems.

Everyone industrial furnace At ENA, every system is individually planned, designed, and manufactured. We tailor each system precisely to the specific production processes, materials, and requirements of our customers. From the initial concept phase through design and commissioning, we support you as a competent partner throughout the entire project. Trust in an experienced partner. Industrial furnace construction from Germany, which stands for quality “Made in Germany”.

Our product range in industrial furnace construction

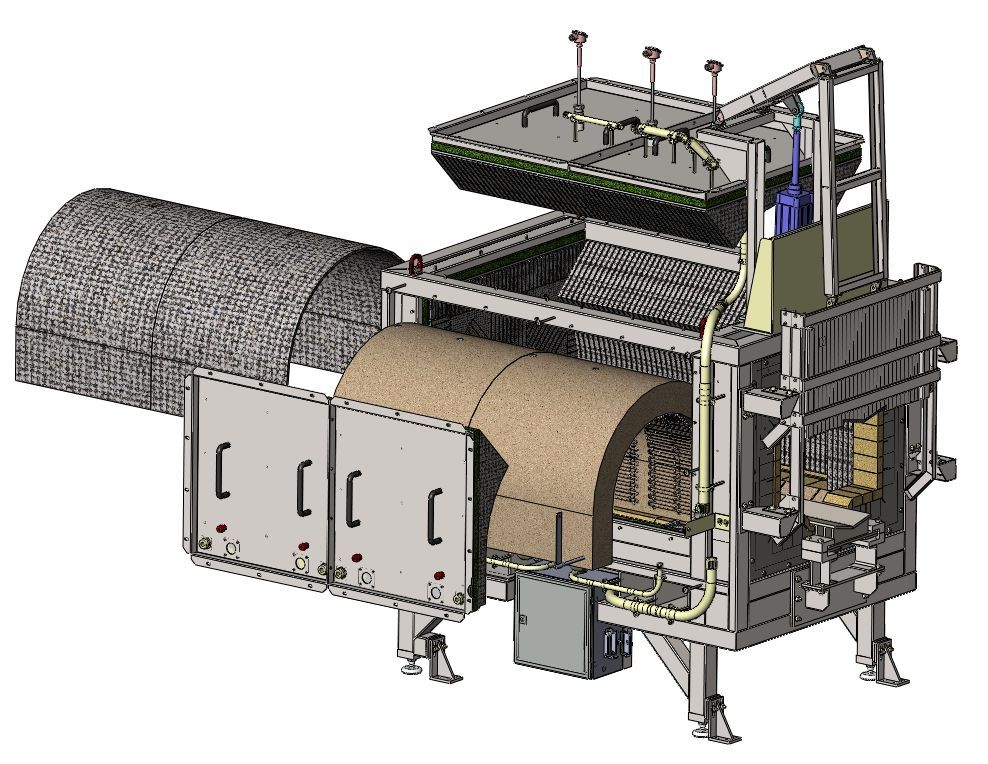

ENA GmbH offers a comprehensive portfolio of high-performance industrial furnace systems for a wide range of applications in heat treatment, tempering, and process heating technology. Our industrial furnace construction includes both standardized solutions and customized special systems.

Continuous ovens

Our continuous furnaces are ideally suited for high-throughput, continuous heat treatment processes. They are frequently used in series production and impress with their uniform temperature distribution, short cycle times, and high energy efficiency.

Tempering ovens

ENA's tempering furnaces enable precise temperature control and homogeneous heat distribution throughout the entire usable space. They are ideal for demanding tempering processes where reproducible results and process reliability are paramount.

Chamber furnaces

Chamber furnaces are flexible all-rounders in industrial furnace construction. They are ideally suited for batch processes and varying component geometries. Their robust design, long service life, and versatile application possibilities make them a proven solution in many industrial sectors.

Convection ovens

Our convection ovens ensure exceptionally even temperature distribution thanks to their high-performance convection systems. They are ideal for applications where consistent temperatures throughout the entire usable space are crucial, such as tempering or drying.

Special systems and customer-specific industrial furnace construction

In addition to classic industrial furnaces, we also realize customized special systems according to individual customer specifications. These include, among others, rotary table furnaces, paternoster furnaces, and other specially developed industrial furnace concepts for particular processes and production requirements.

Your partner for professional industrial furnace construction

Are you looking for a reliable and experienced partner for industrial furnace construction, a new industrial furnace, or a customized furnace system? ENA Industrieofenbau GmbH offers expert advice, detailed process analysis, and a solution tailored to your specific requirements.

Our team of experts will guide you from planning to implementation, ensuring your system is efficient, durable, and future-proof. ENA stands for quality, innovation, and cost-effective industrial furnace construction – Made in Germany.

FAQ – Frequently Asked Questions about Industrial Furnaces

What is an industrial furnace?

An industrial furnace is an industrial heat treatment system used for the controlled heating of components and materials. Industrial furnaces are used for processes such as tempering, annealing, drying, curing, sintering, and preheating, and are designed for continuous industrial operation.

What types of industrial furnaces are there?

The most common types of industrial furnaces include:

Convection ovens

Chamber furnaces

Continuous ovens

hearth wagon ovens

Hood-type ovens

Turntable ovens

Paternoster ovens

Vacuum ovens

Special and custom furnaces

The selection depends on the thermal process, the throughput, and the component dimensions.

What are industrial furnaces used for?

Industrial furnaces are used in many industries, e.g.: metal processing & heat treatment

Automotive industry, plastics processing, electrical engineering, chemicals & materials engineering, construction and insulation materials industry

What temperatures do industrial furnaces reach?

Modern industrial furnaces typically operate in a temperature range of 50 °C to 1,300 °C. Special designs can also achieve higher temperatures.

Electrically or gas-fired industrial furnace – which is better?

Electrically heated industrial furnaces offer high temperature accuracy, clean processes and low maintenance.

Gas-fired industrial furnaces are economical at very high outputs and large volumes.

The decision depends on energy efficiency, operating costs, and process requirements.

What is the difference between a batch furnace and a continuous furnace?

Batch ovens are loaded in batches and are suitable for flexible production quantities.

Continuous furnaces allow for a continuous flow of material and are ideal for high production volumes and automated processes.

How energy-efficient are modern industrial furnaces?

Modern industrial furnaces are very energy-efficient thanks to: high-performance insulation, forced air and recirculation systems.

Heat recovery, intelligent PLC control, and energy efficiency permanently reduce operating costs.

What size should an industrial furnace be?

The oven size depends on: component size and weight, batch or throughput capacity, cycle times

Future expansions

Many companies rely on custom-designed industrial furnaces to save space and energy.

How is an industrial furnace controlled?

Industrial furnaces are usually operated via PLC/SPS controllers with touchscreens. Functions include:

Recipe Management

Temperature and process monitoring, data acquisition and logging, connection to MES and ERP systems

What standards and guidelines apply to industrial furnaces?

Important standards include: CE marking, EN 746, Machinery Directive, and operational safety requirements.

These ensure safety, process stability, and legal compliance.

How maintenance-intensive are industrial furnaces?

Industrial furnaces require little maintenance when properly designed. Regular maintenance includes:

Checking the heating elements, checking the fans, calibrating the temperature sensors

How long is the delivery time for industrial furnaces?

Standard industrial furnaces: 8–12 weeks. Customized industrial furnaces: 3–9 months. Delivery time depends on the degree of customization.

Why choose industrial furnaces “Made in Germany”?

Industrial furnaces from Germany stand for: High quality, long service life, spare parts availability, and customized solutions.

Reliable service

Background: Industrial furnacesIndustrial furnace Wikipedia

Wikipedia defines industrial furnaces as enclosed heat chambers; classified according to design (chamber, continuous, shaft furnaces), material intake, heating (electric, fuel), enclosing material and process (melting, heat treatment) for diverse materials and production areas, such as metal, glass, ceramics.