ENA fan ovens / fan ovens

Industrial furnace construction - Convection furnaces - Convection furnaces and industrial furnaces

Optimal temperature distribution with convection ovens / industrial ovens

Industrial ovens with convection technology – Efficient and even heat distribution

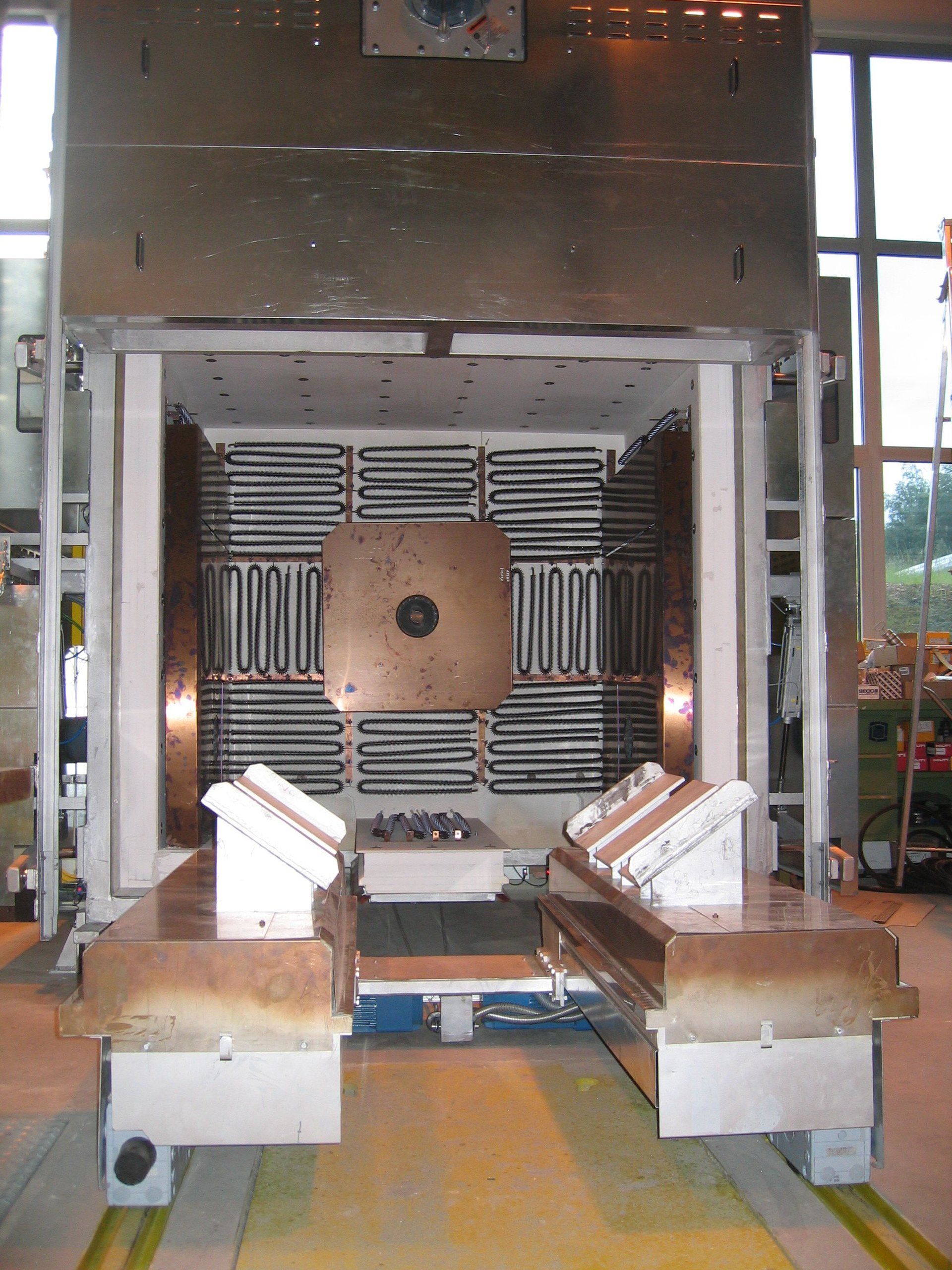

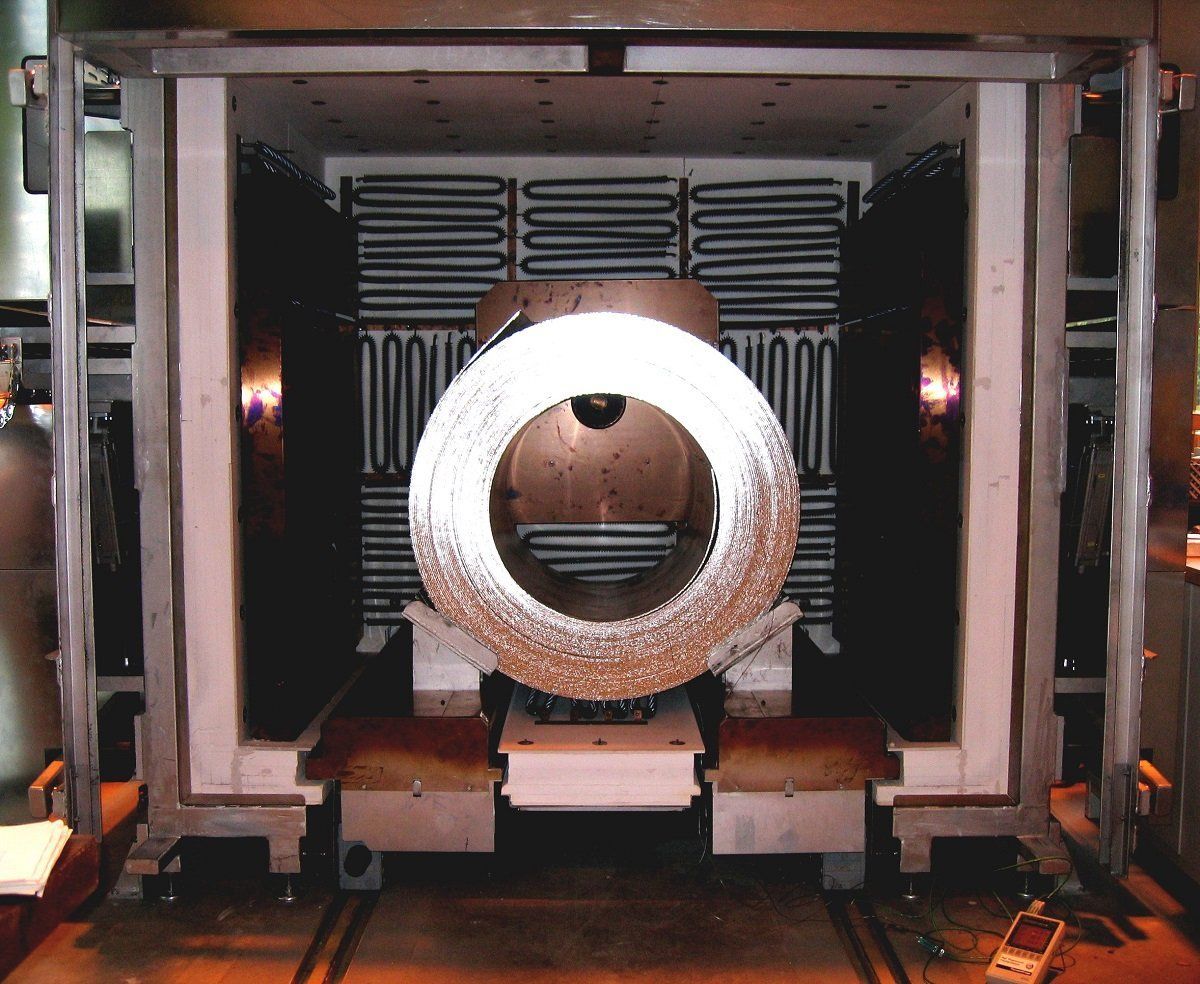

Modern convection ovens and industrial furnaces offer precise and uniform heat distribution – a crucial factor for reliable heat treatment processes. At the heart of this technology are high-performance fans that ensure controlled and homogeneous temperature distribution throughout the entire interior of the oven.

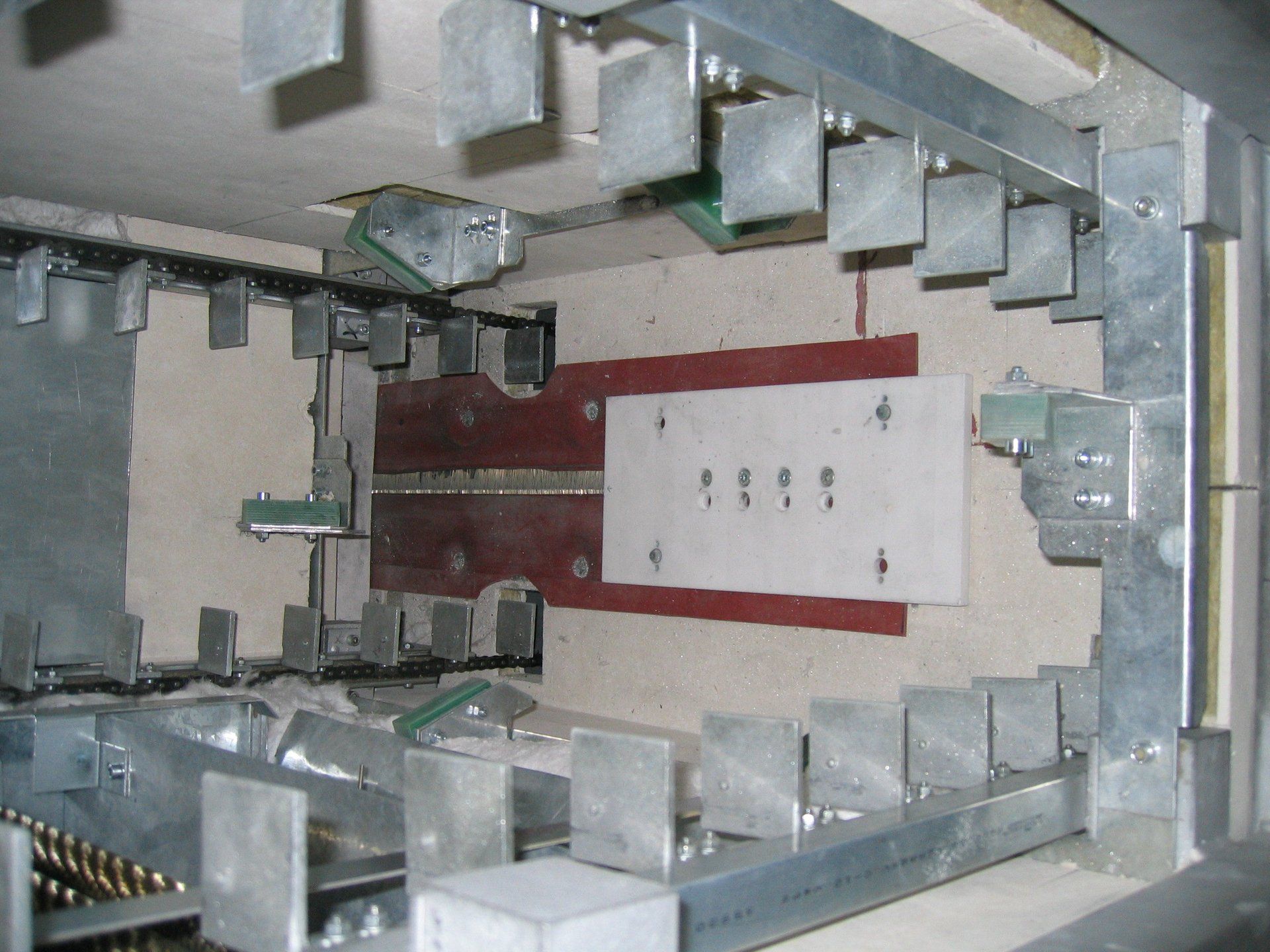

Depending on the requirements and the geometry of the furnace, fans in different designs are used – both horizontally and vertically arranged. This targeted airflow ensures that the heat is transferred evenly to the workpiece – regardless of its shape, size, or material.

Versatile designs: Convection ovens and other types of industrial ovens

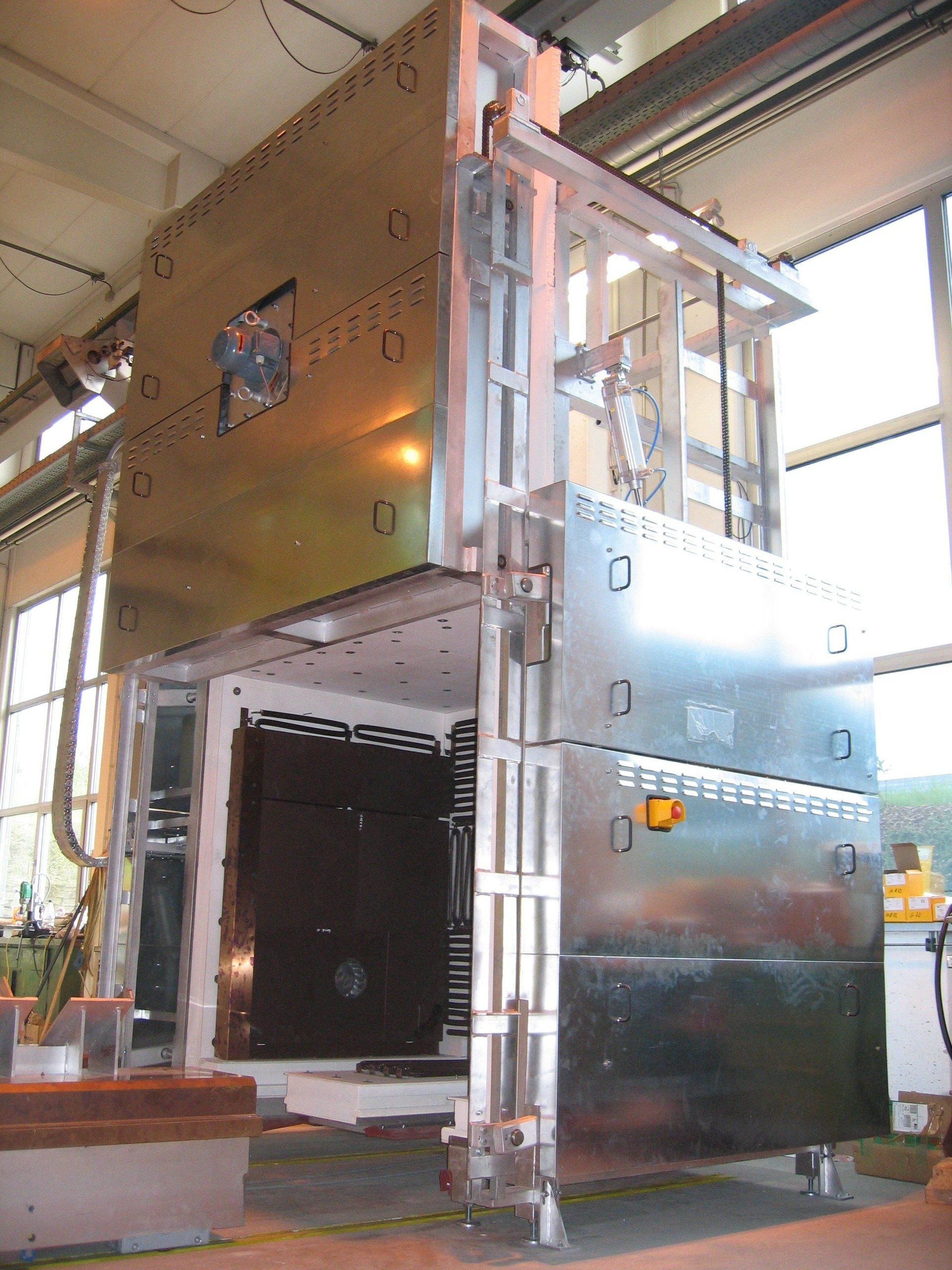

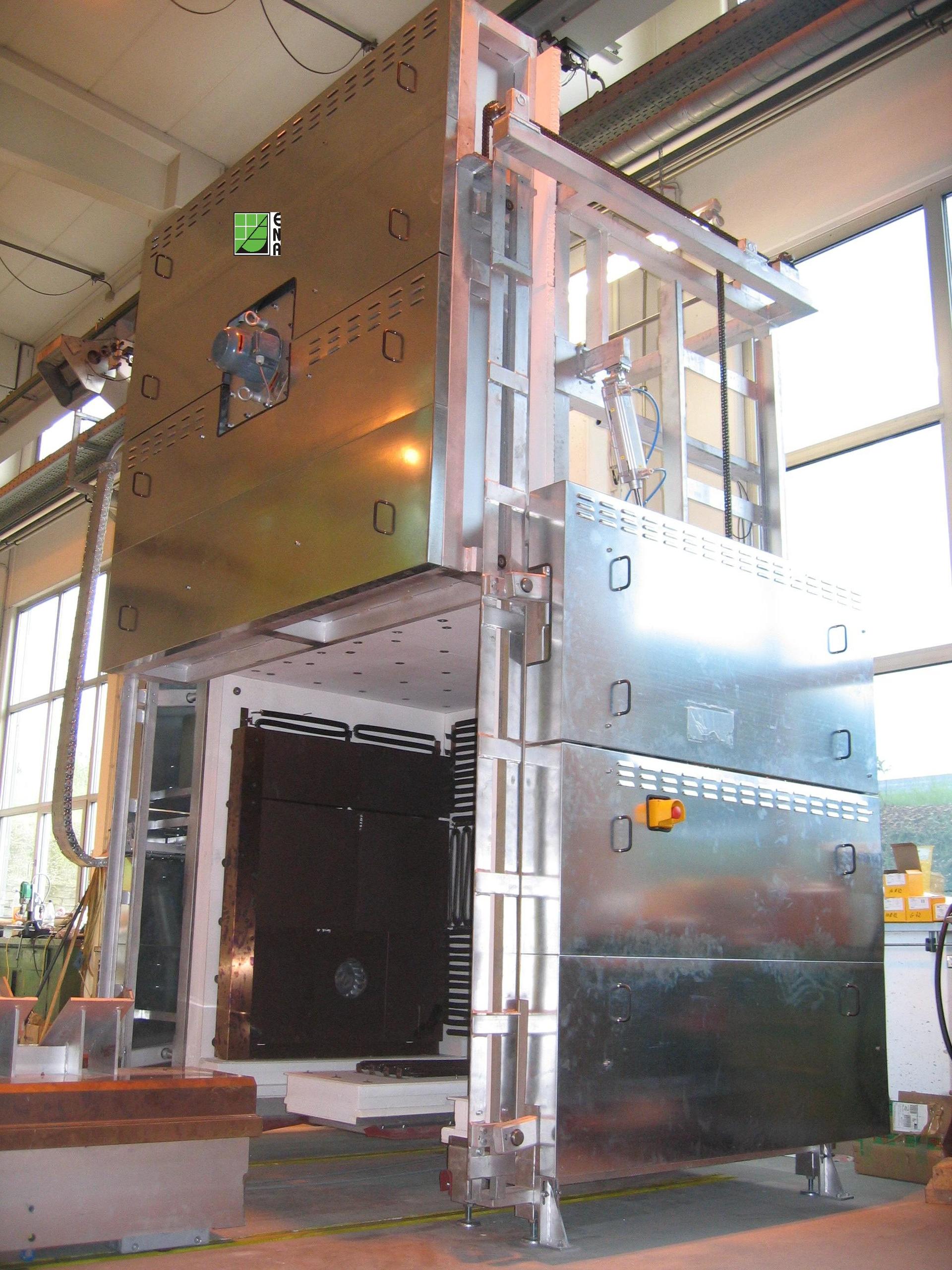

Our convection ovens are available in various designs and can be individually adapted to the specific application. They are most commonly used as chamber ovens or tempering ovens. However, other industrial oven variants are also available for special applications, such as:

Hearth trolley furnaces – ideal for large and heavy workpieces, easily loaded and unloaded thanks to extendable trolleys.

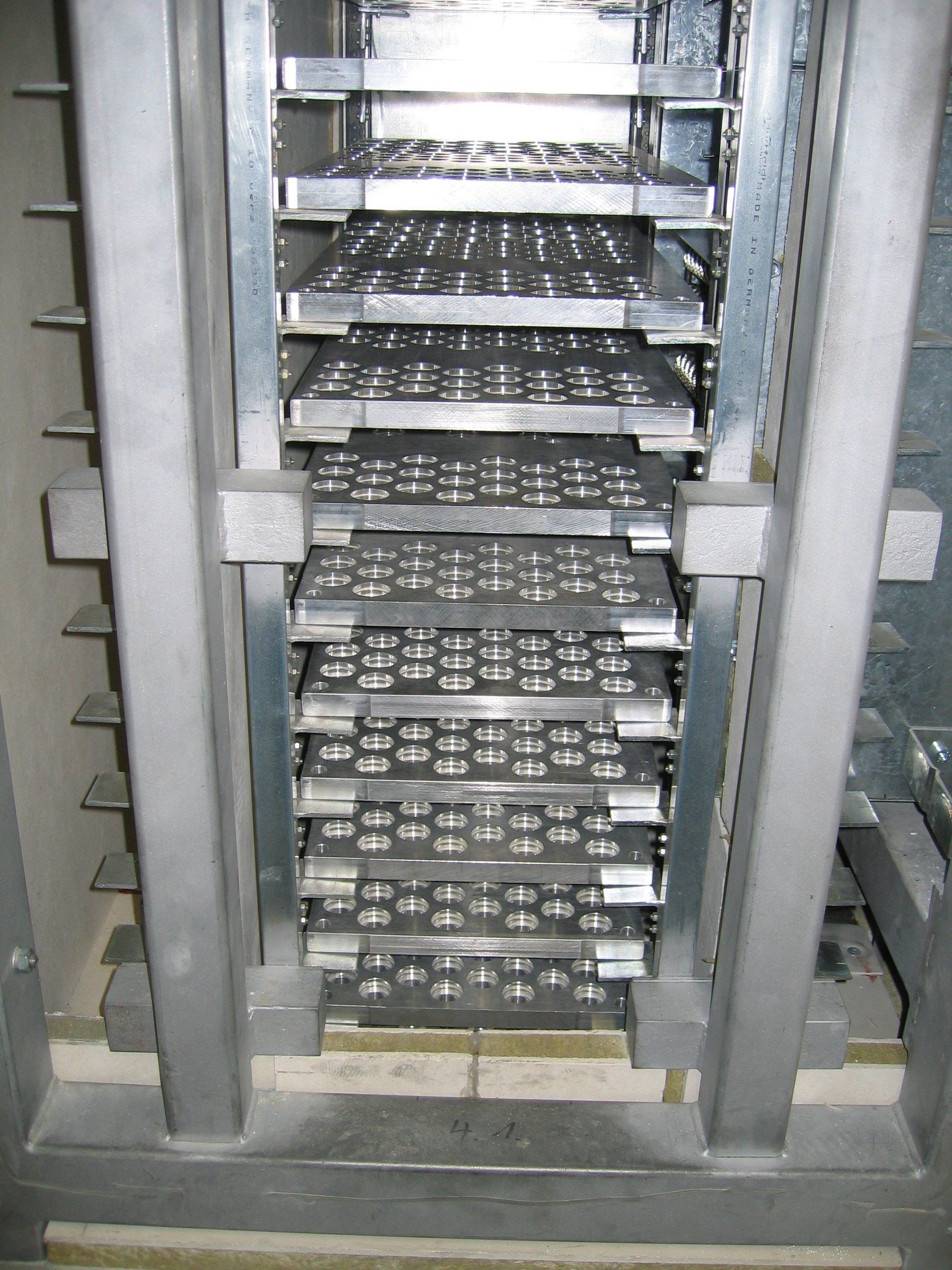

Paternoster furnaces – for continuous processes and space-saving vertical installations.

Continuous furnaces (continuous furnace) – ideal for high production volumes in continuous production, e.g. in the automotive or electrical industries.

This diversity allows for precise adaptation to industry-specific requirements – from tempering furnaces to hardening ovens and special solutions.

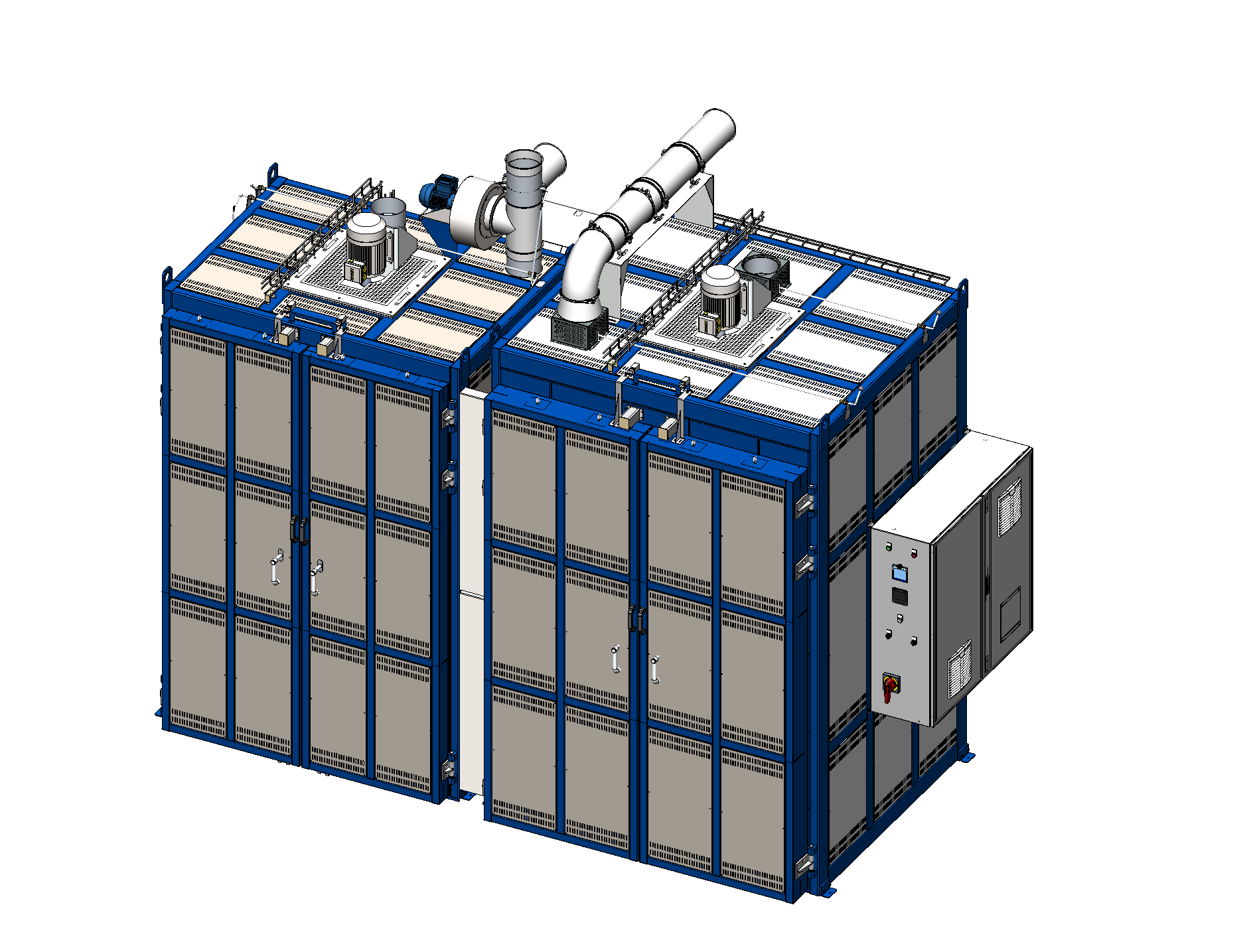

Custom design for maximum process reliability

Every industrial furnace with forced-air technology is designed, engineered, and manufactured according to specific customer requirements. Alternatively, proven standard designs are available, which we adapt to your processes. From low-temperature heat treatment to high-temperature hardening, our systems cover a wide range of industrial applications.

Technical specifications of our convection ovens:

Temperature range: 180 – 950 °C (special versions for higher temperatures available on request)

Recirculation systems: horizontal, vertical or combined

Heating technologies: electrically or gas-heated

Control systems: modern PLC-based control for precise process control

Installation space sizes: flexibly scalable according to product requirements

Why choose a convection oven from us?

High energy efficiency through optimized airflow

Uniform heat distribution for reproducible results

Extensive experience in furnace construction for industrial applications

Customized adjustments for maximum productivity

🔍 Request a quote for the perfect industrial oven with convection technology now!

Are you looking for a reliable convection oven, continuous oven, or other industrial oven for your production? We would be happy to advise you and develop the optimal solution for your requirements.