Custom-made tempering ovens from Germany for the highest demands

Precise heat treatment with the appropriate tempering furnace

The targeted heat treatment of components is a crucial process step for ensuring quality and longevity. As a specialist in industrial furnace construction, ENA GmbH offers highly precise and reliable solutions. Tempering ovens For diverse applications. Our systems, developed and manufactured in Germany, guarantee optimal results. Tempering of plastics, metals and other materials. Each Tempering oven It will be tailored precisely to your specific requirements.

What is tempering and why is a high-quality tempering oven crucial?

In tempering, workpieces are heated in a controlled manner and held at a specific temperature for a defined period before being cooled in a controlled manner. This process reduces internal stresses in the material, improves its mechanical properties, and increases dimensional stability. Precisely controlled tempering is particularly important when processing plastics. Plastic tempering oven essential to avoid warping and ensure a homogeneous material structure. Our Tempering furnaces are designed for these demanding tasks.

Application areas of our tempering furnaces

Our industrial furnaces and Tempering furnaces Germany They are used in numerous industries and prove their efficiency and reliability every day. Typical applications include:

- Stress-relief annealing: Reduction of residual stresses in plastic and metal components after machining.

- Curing and cross-linking: Heat treatment of thermosets, elastomers, as well as paints and adhesives.

- Drying: Removal of residual moisture from materials under controlled conditions.

- Aging: Accelerated aging processes to simulate material behavior over time.

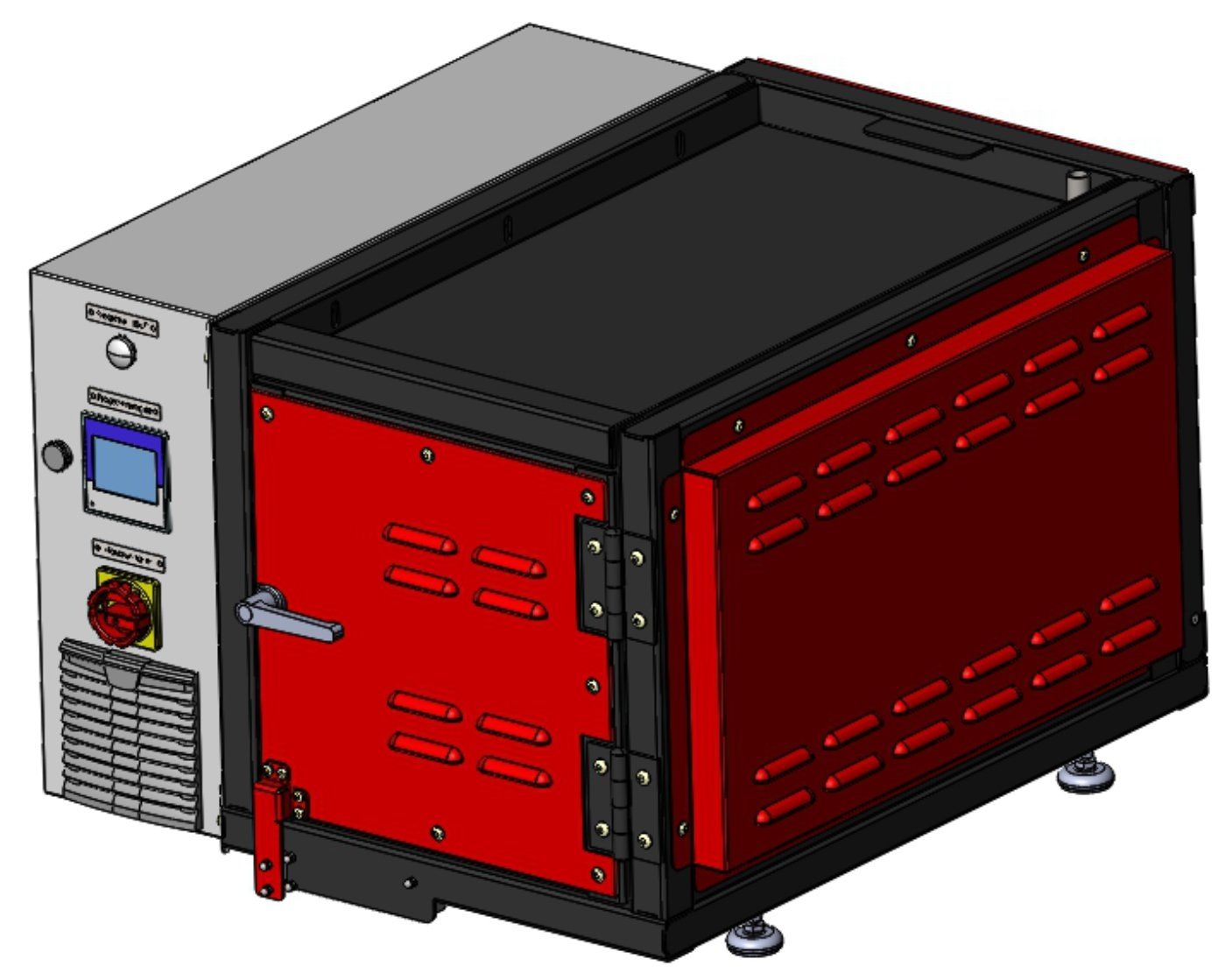

- Chamber stoves & drawer stoves: Ideal for batch processes and laboratory applications.

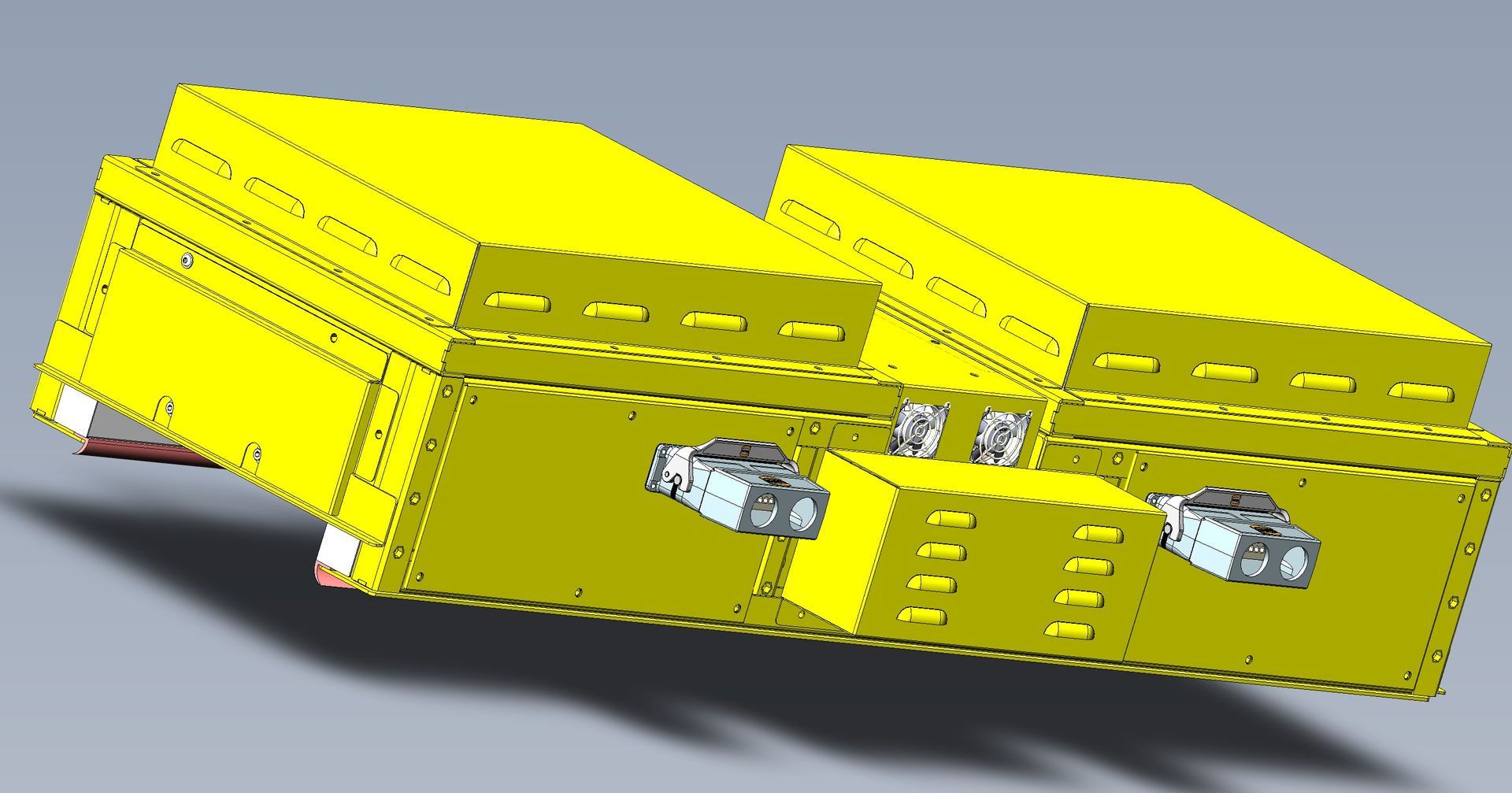

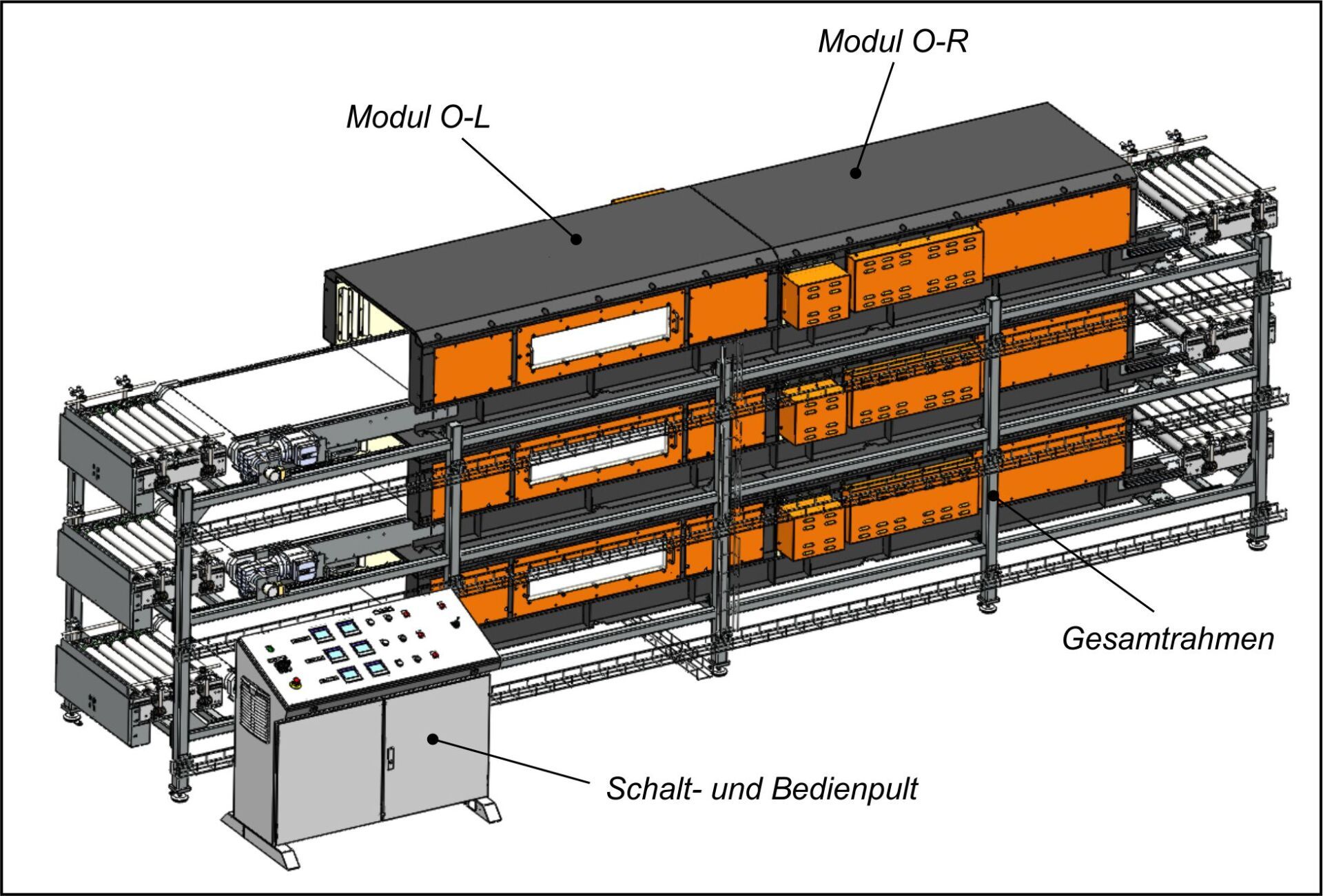

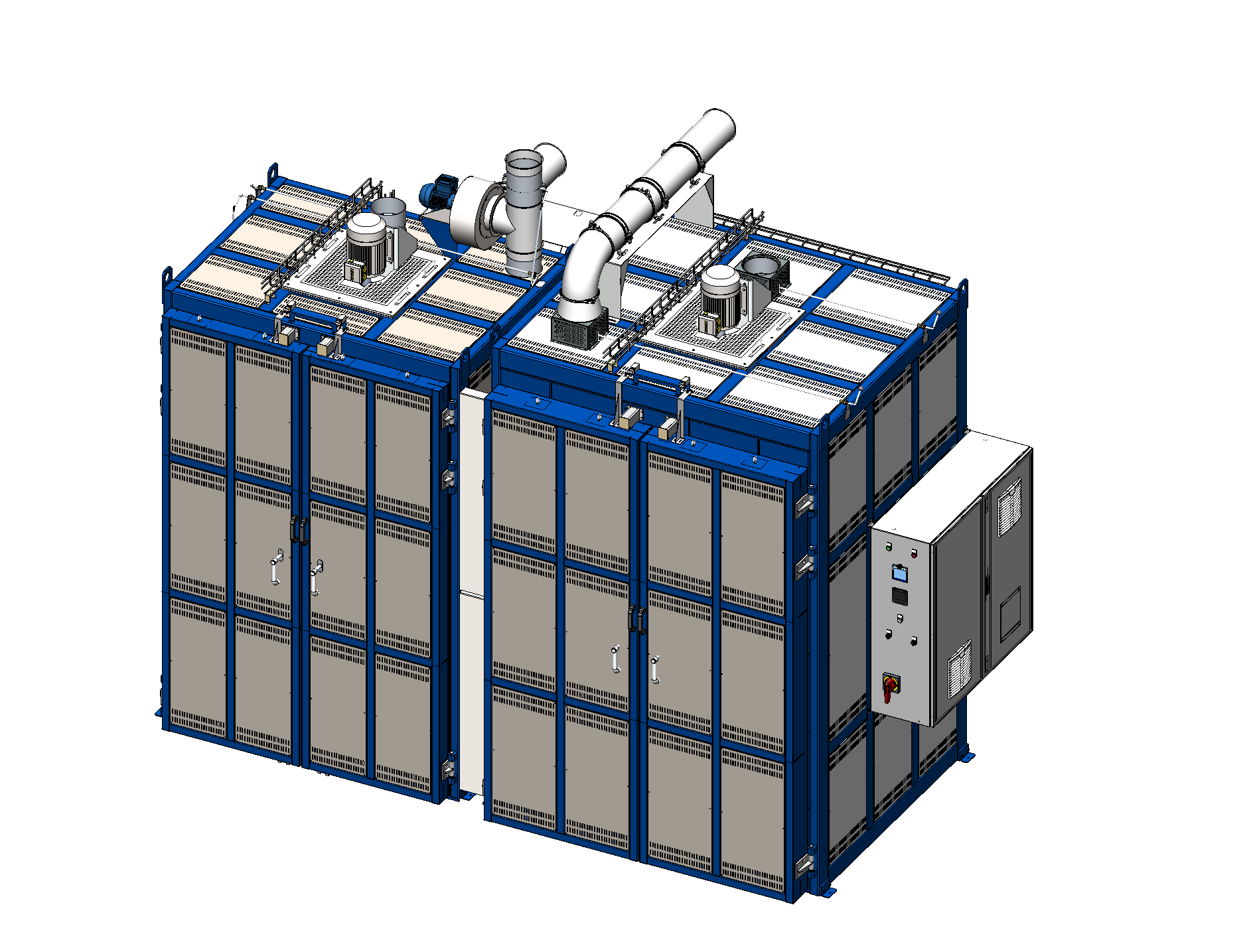

- Continuous furnaces: Perfect for continuous production processes and a high degree of automation.

- Paternoster ovens: Space-saving solutions for vertical heat treatment.

Preheating: Targeted heating of components for subsequent process steps such as welding or coating.

Flexible industrial furnace construction tailored to your requirements.

We understand that every manufacturing process is unique. Therefore, we offer a wide variety of designs for our products. Tempering ovens which can be flexibly integrated into your production line:

Our standard models cover a temperature range up to 650 °C. For special requirements, we are happy to develop customized solutions with higher temperature capabilities. Contact us for a personalized consultation regarding your new [product/service]. Tempering oven for industry and trade.