ENA Industrial Furnace Construction Continuous Furnace

Continuous furnaces / continuous furnaces Germany, tunnel furnaces / tunnel furnaces and industrial furnaces

Continuous furnaces for industrial heat treatment processes in Germany

Efficient industrial furnaces – continuous furnaces for continuous production

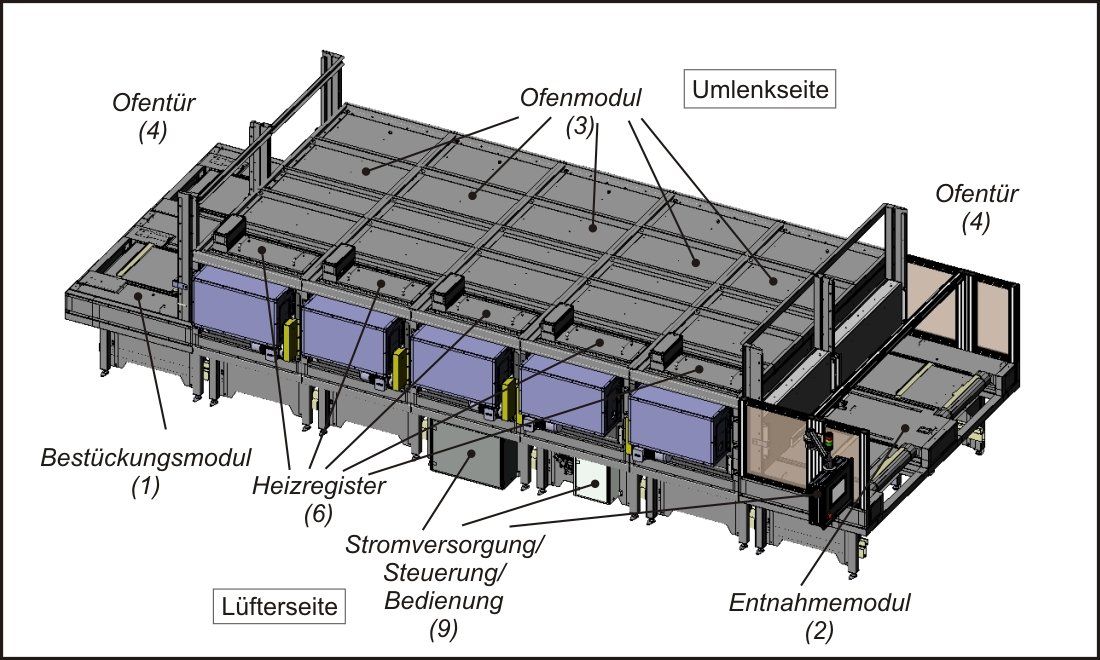

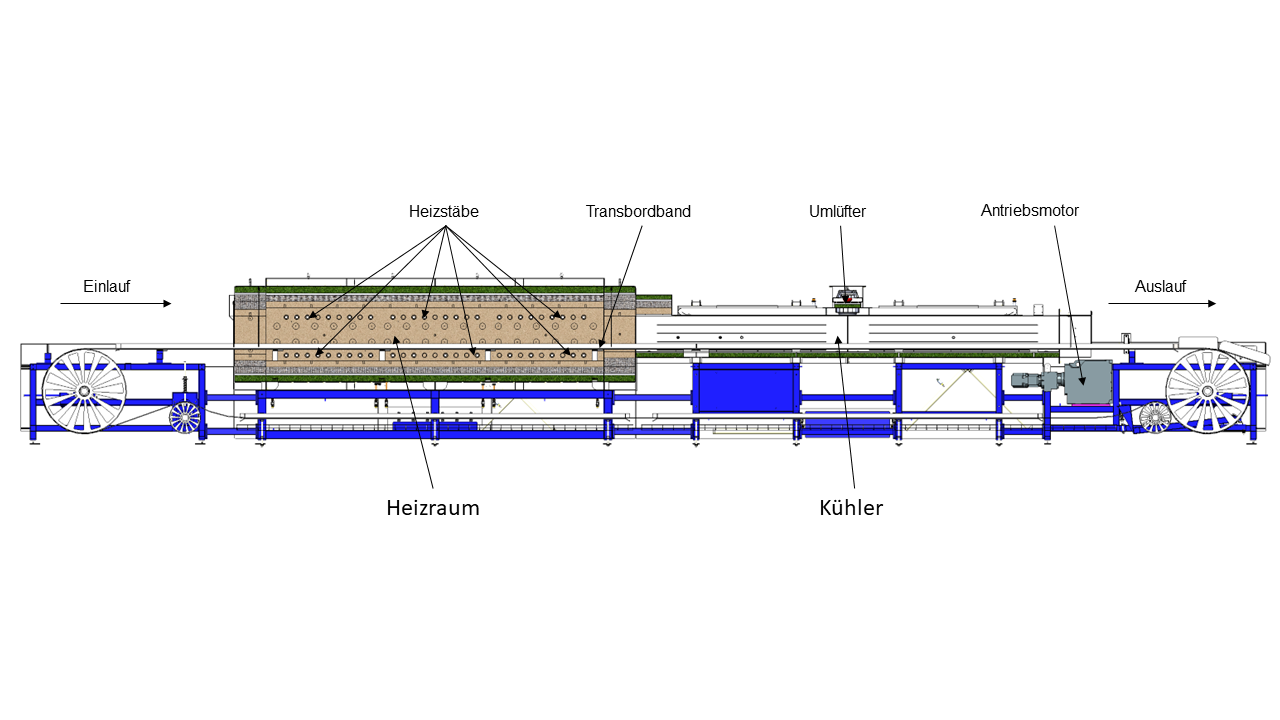

A modern continuous furnace (also known as a tunnel furnace) is an indispensable element in industrial manufacturing, especially in high-throughput applications. Its characteristic design, with two opposing openings—one for loading and one for unloading workpieces—enables efficient, continuous processing. The furnace doors can be opened and closed independently, minimizing downtime and optimizing material flow.

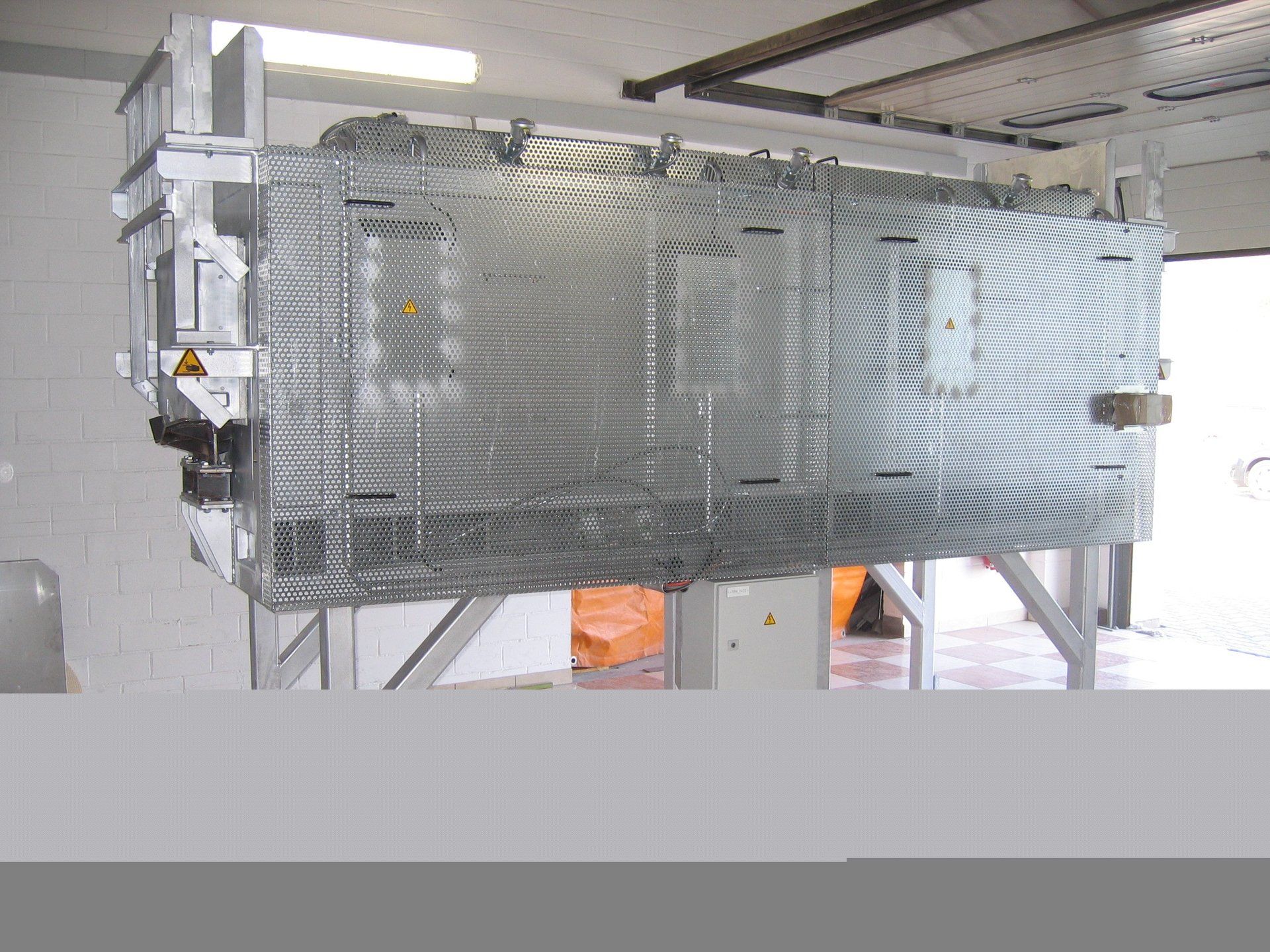

Our continuous furnaces in Germany are manufactured specifically for various industries such as automotive, metal processing, aerospace, electrical engineering, and plastics technology. The design is always based on your specific process parameters.

Applications and advantages of industrial continuous furnaces

The industrial furnaces presented here are ideally suited for various heat treatment processes, such as tempering, soft annealing, stress-relief annealing, and hardening of metals and other materials. The continuous furnaces can be equipped with either pneumatically or electromechanically operated doors. The furnaces can be loaded manually, semi-automatically, or fully automatically, allowing for a high degree of flexibility in daily production.

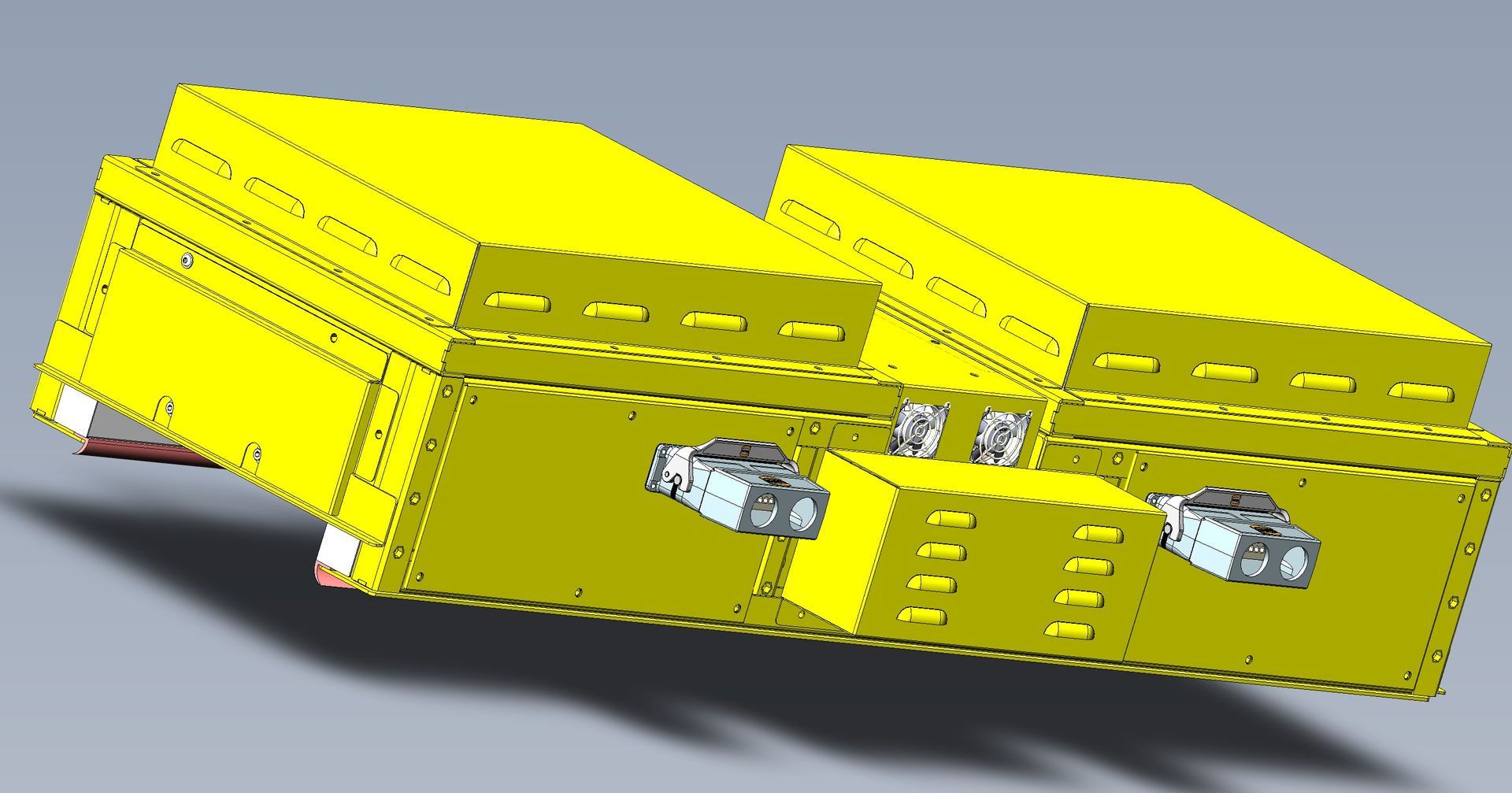

Thanks to their modular design, our industrial continuous furnaces can also be expanded later or adapted to new production lines.

Precise temperature control through segmented heating zones

A key feature of our continuous furnaces is the division of the heating chamber into several individually controlled temperature zones. This segmentation enables precise control of the heat treatment along the entire length of the furnace. Temperature deviations are thereby reduced to a minimum, which significantly increases the quality and reproducibility of the treated workpieces.

Technical features at a glance:

Temperature range: up to 1,000 °C, higher temperatures on request

Number and length of heating zones: individually adjustable

Control: modern PLC-based control technology

Energy supply: electric, gas-heated or hybrid systems

Continuous furnaces “Made in Germany” – individually designed for your production

Our continuous furnaces, manufactured in Germany, are developed precisely according to your production requirements and workpiece specifications. From laboratory use to high-volume production – each system is individually designed and equipped with state-of-the-art control technology. Our industrial furnaces are designed for maximum efficiency, durability, and energy savings.

Whether classic continuous furnace, tunnel furnace or special designs for protective gas atmospheres – we offer you a comprehensive portfolio and support you from planning to commissioning.

Find the right industrial furnace now!

Are you looking for a continuous furnace for your industrial application? Contact us for a free consultation. Together, we will develop the optimal solution for your production.

➡️ Request a quote for a continuous furnace now and secure individual consultation!