ENA rotary kilns / rotary kiln industrial kilns

Rotary table furnaces or rotary table furnaces / industrial furnaces as a special type of continuous furnace

Efficient heat treatment for highly automated processes

Rotary table furnaces – Efficient industrial furnaces for automated production lines, mass and series production.

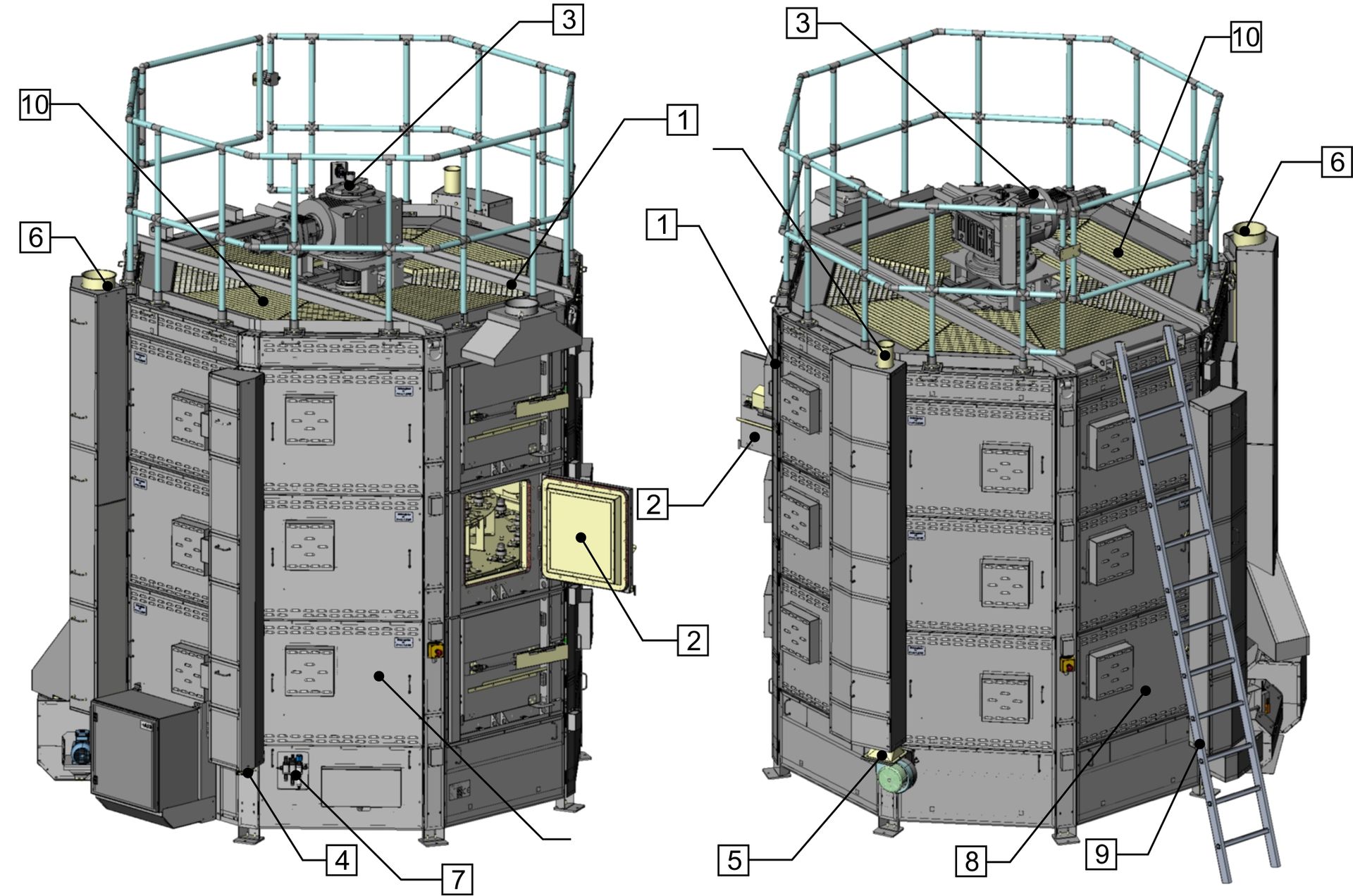

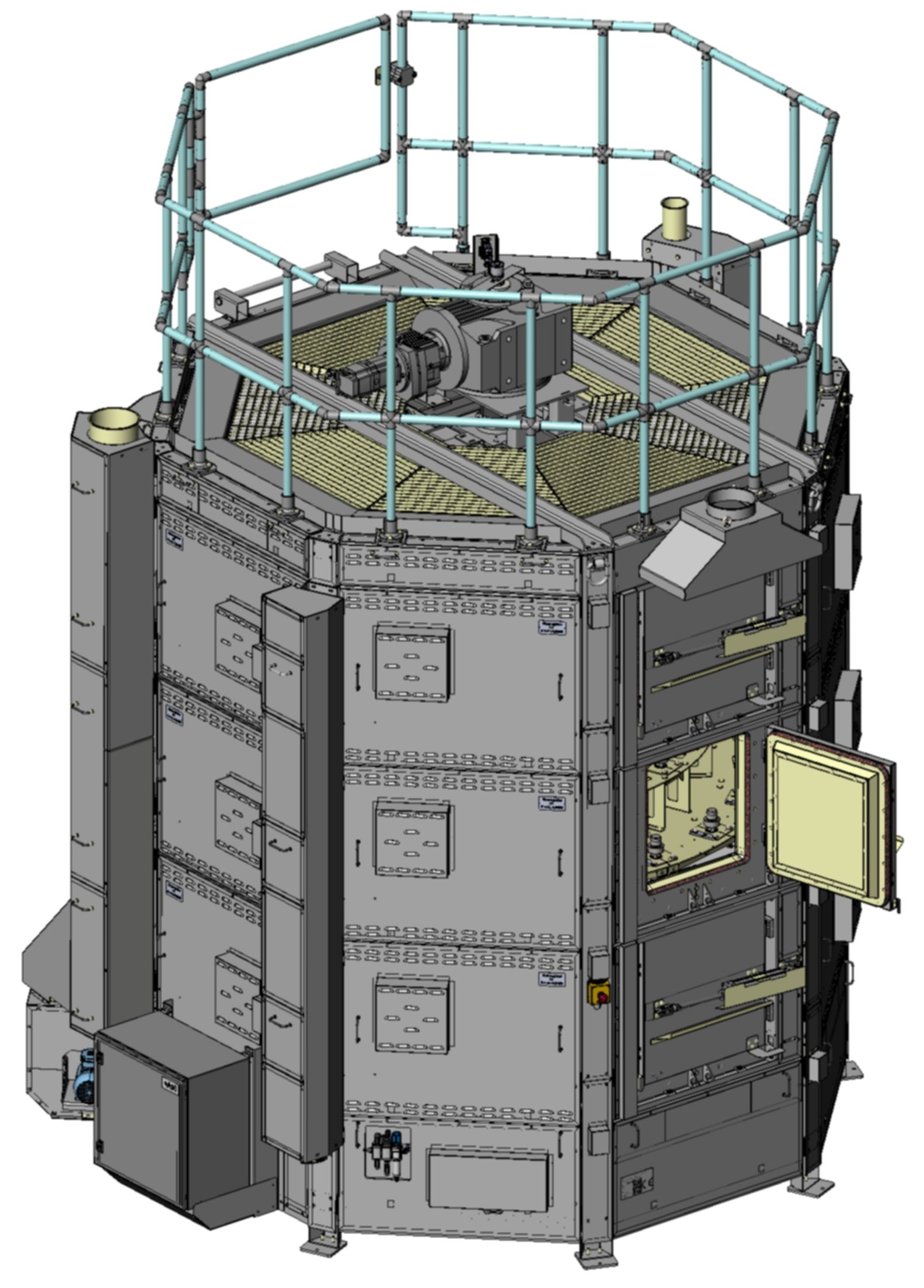

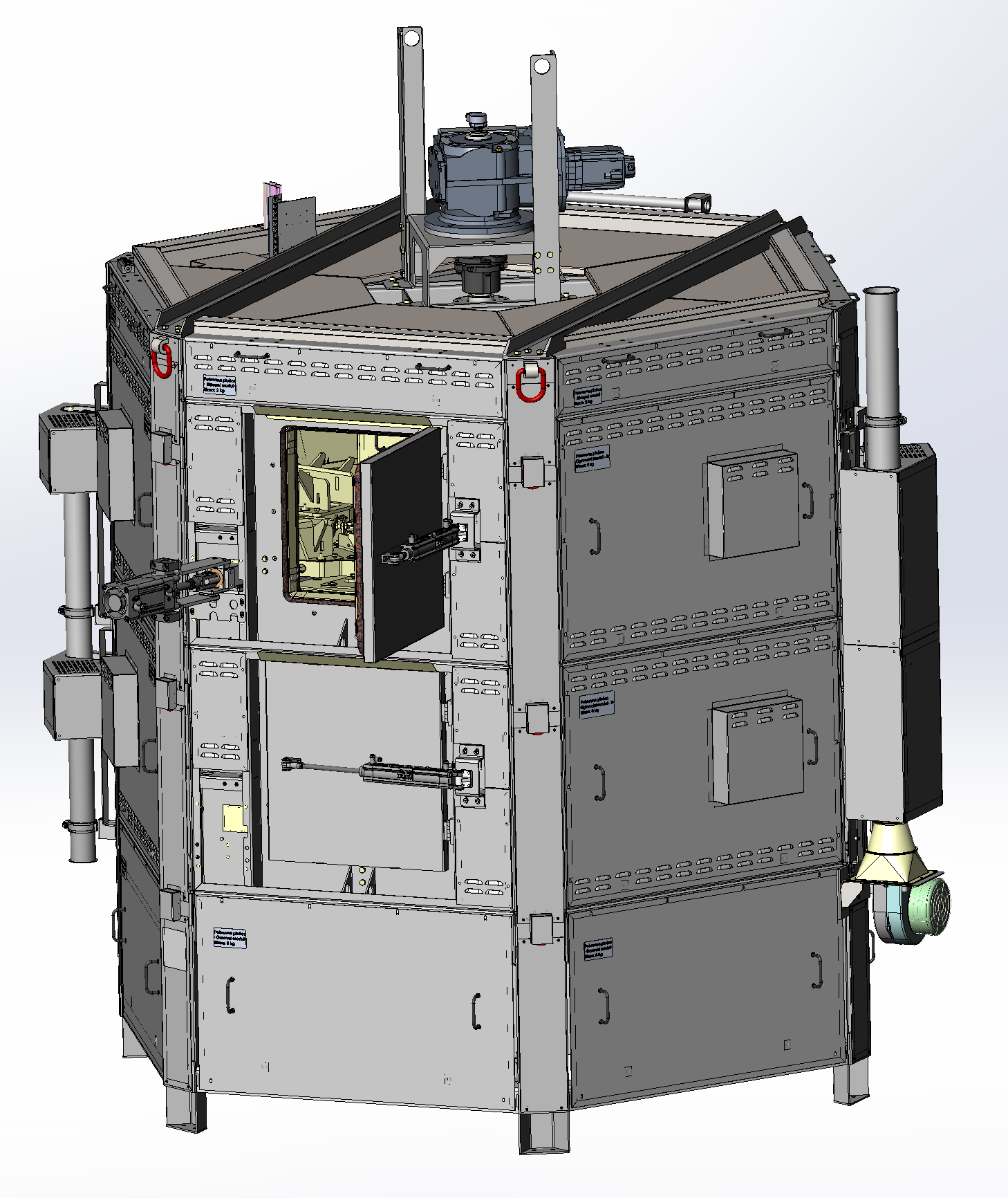

Rotary furnaces, also known as rotating continuous furnaces or circular track-based industrial furnaces, are specifically designed for timed, highly automated heat treatment processes in modern industrial production. This innovative design of continuous furnace utilizes a rotating platform to efficiently transport workpieces through different temperature zones – ideal for high-throughput applications with short cycle times.

Especially in the automotive industry, for example in the production of electric motors for electric vehicles, companies are increasingly relying on rotary table furnace technology to balance speed, precision and energy efficiency. However, this furnace design is also being used successfully in other industries such as medical technology, aerospace and electronics manufacturing.

Robot-based assembly and maximum automation

Our rotary table furnaces are designed to meet the requirements of automated production processes. The combination of a compact design and intelligent control allows for seamless integration into robotic cells and production lines. Loading and unloading of workpieces is fully automated – without manual intervention.

Advantages at a glance:

Ideal for robotic loading: automated workpiece flow with constant process flow

High cycle rates: optimized for maximum output with minimal time expenditure

Uniform heat treatment: precise temperature control through segmented heating zones

Compact design: space-saving integration into existing production facilities

Technical characteristics and classification

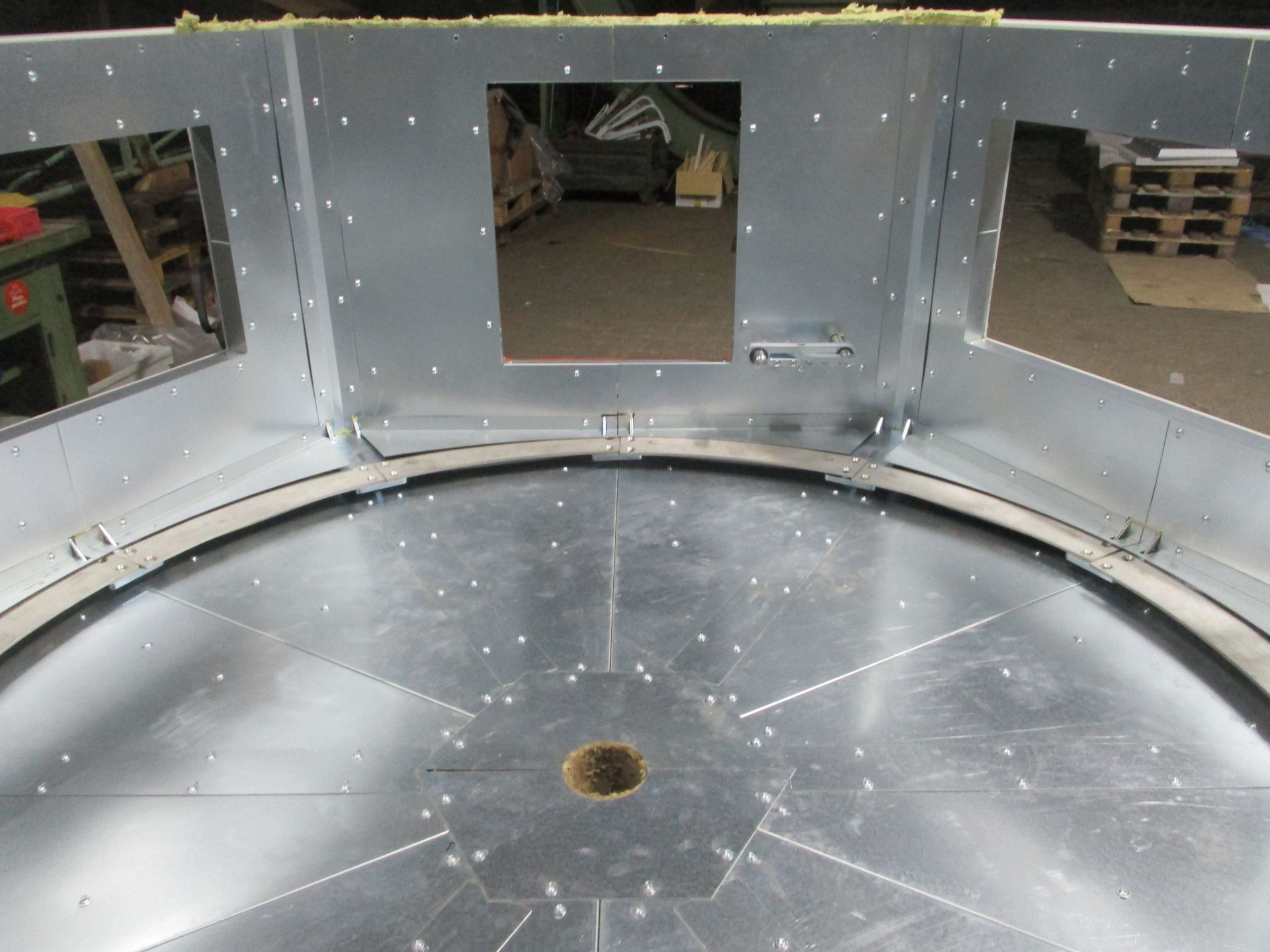

A rotary table furnace belongs to the group of continuous furnaces, but differs in its circular transport system. Instead of moving linearly, the workpiece carriers move on a rotating turntable, which is guided continuously or intermittently through heating zones and, if applicable, cooling areas.

Typical technical features:

Temperature range: depending on the model, up to 650 °C or more

Cycle time: adaptable to the manufacturing process (e.g. <10 seconds per station)

Heating: electric, optional, zone-controlled

Atmosphere control: air, protective gas or vacuum possible

Interfaces: compatible with robot control, PLC and MES systems.

This design is ideally suited for the heat treatment of small to medium-sized components, e.g. copper windings, steel components or hybrid mounted units.

Flexibility and efficiency in heat treatment

Thanks to their modular design, rotary table furnaces can be precisely tailored to your requirements – from the number of stations and the size of the workpiece carriers to the type of heating and cooling. The combination of a high degree of automation, short cycle times, and a small footprint makes them the perfect solution for modern Industry 4.0 production.

Compared to classic industrial furnaces or linear continuous furnaces, rotary table furnaces often offer significantly higher energy efficiency, as heat is used more effectively and heat losses are minimized.

Applications & Industries

Typical applications of rotary table furnaces:

Manufacturing of electric motors and stators

Heat treatment of fasteners

Tempering of plastics and adhesive bonds

Preheating and drying in electronics manufacturing

Fast cycle times in automated assembly lines

Request a quote for the perfect turntable oven now!

Are you looking for a state-of-the-art, space-saving and automatable solution for your heat treatment processes? Our rotary table furnaces offer you the perfect combination of efficiency, process reliability and flexibility.

📞 Contact us for a personal consultation – we will work with you to develop the optimal solution for your production!