Chamber furnaces, chamber furnaces, heat treatment plants

Chamber furnaces for industry – Efficient heat treatment with custom-designed chamber furnaces

What is a chamber oven?

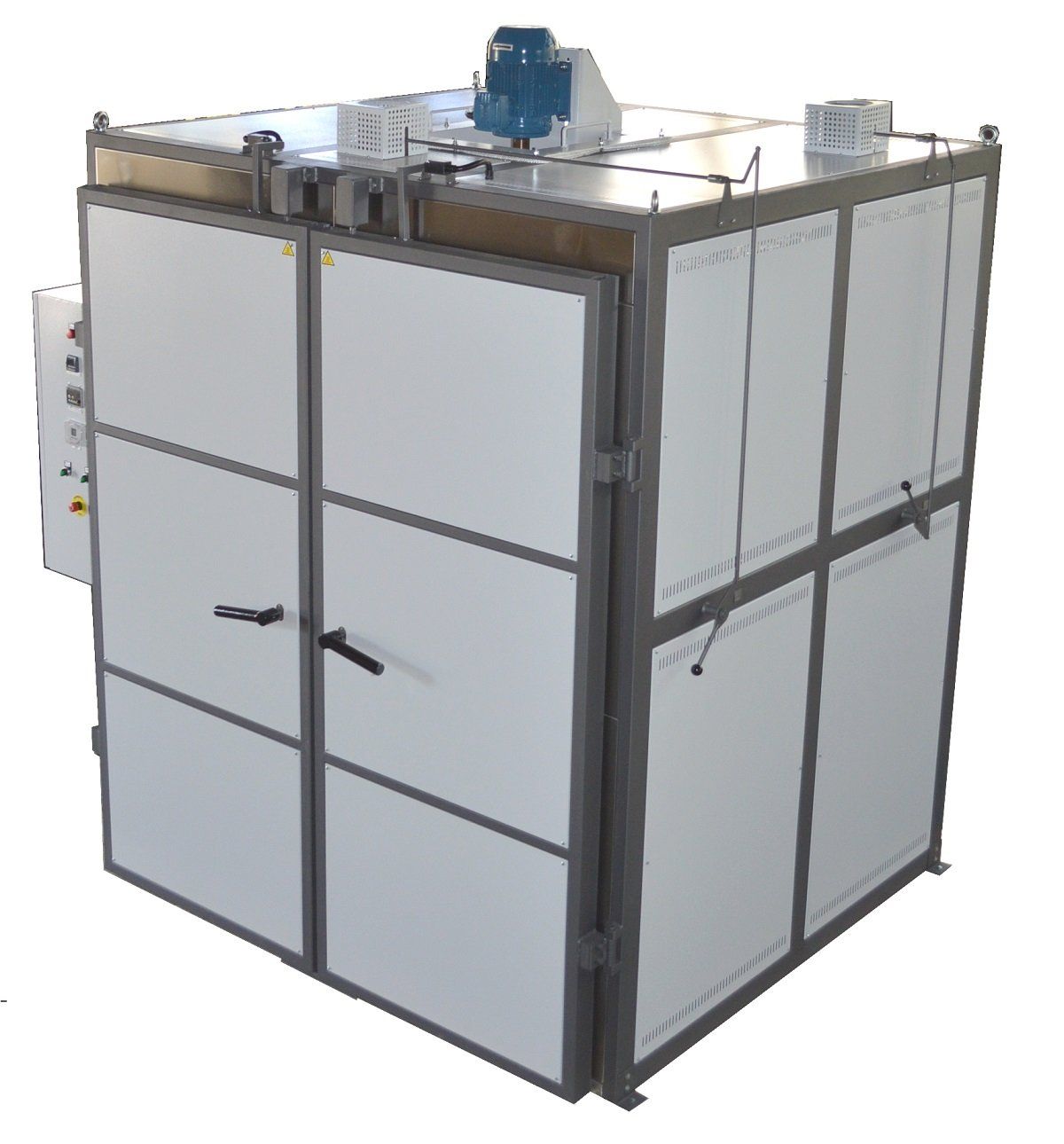

A chamber furnace is a classic industrial furnace and a key tool in modern industrial furnace construction. It is used for the thermal treatment of a wide variety of materials such as metals, plastics, and glass, and is employed in diverse industries – from automotive and aerospace to medical technology and laboratory environments. A typical chamber furnace consists of a well-insulated, heat-resistant furnace chamber with precise temperature control. Thanks to its compact and robust design, it is extremely versatile and durable.

Applications for chamber furnaces in industry

Chamber furnaces are used wherever controlled heat treatment is required. This includes processes such as:

Hardening and tempering of steel parts

Drying of coatings, varnishes or workpieces

Degassing of plastic components

Thermal degreasing for surface preparation

Preheating metals before forming

Changing material properties through targeted temperature control

Controlled heating allows for the targeted manipulation of material properties such as hardness, strength, and ductility. Compact chamber furnaces are also ideal for laboratory applications, as they enable uniform temperature distribution and flexible batch processing.

Advantages of a chamber furnace in industrial applications

A high-quality industrial furnace in the form of a chamber furnace offers numerous advantages:

High temperature accuracy: Modern control systems enable precise temperature control and thus reproducible processes.

Energy efficiency: Advanced insulation and optimized heating technology reduce energy consumption.

Modularity and flexibility: Chamber furnaces can be individually adapted to specific workpieces, production quantities and processes.

Durability and robustness: High-quality materials and well-thought-out designs ensure a long service life – even under demanding conditions.

Flexibility through various opening systems

A key distinguishing feature in industrial furnace construction is the opening system of the chamber furnace. It influences both the ergonomics of loading and unloading as well as the energy efficiency of the process. Commonly used systems include:

Hinged doors: The classic – ideal for larger workpieces or batches.

Hinged lid: Especially used in smaller chamber ovens or laboratory ovens.

Lifting doors: Space-saving and particularly suitable for confined production environments.

Depending on the production environment and available space, the appropriate door system is selected to ensure safety and ease of use.

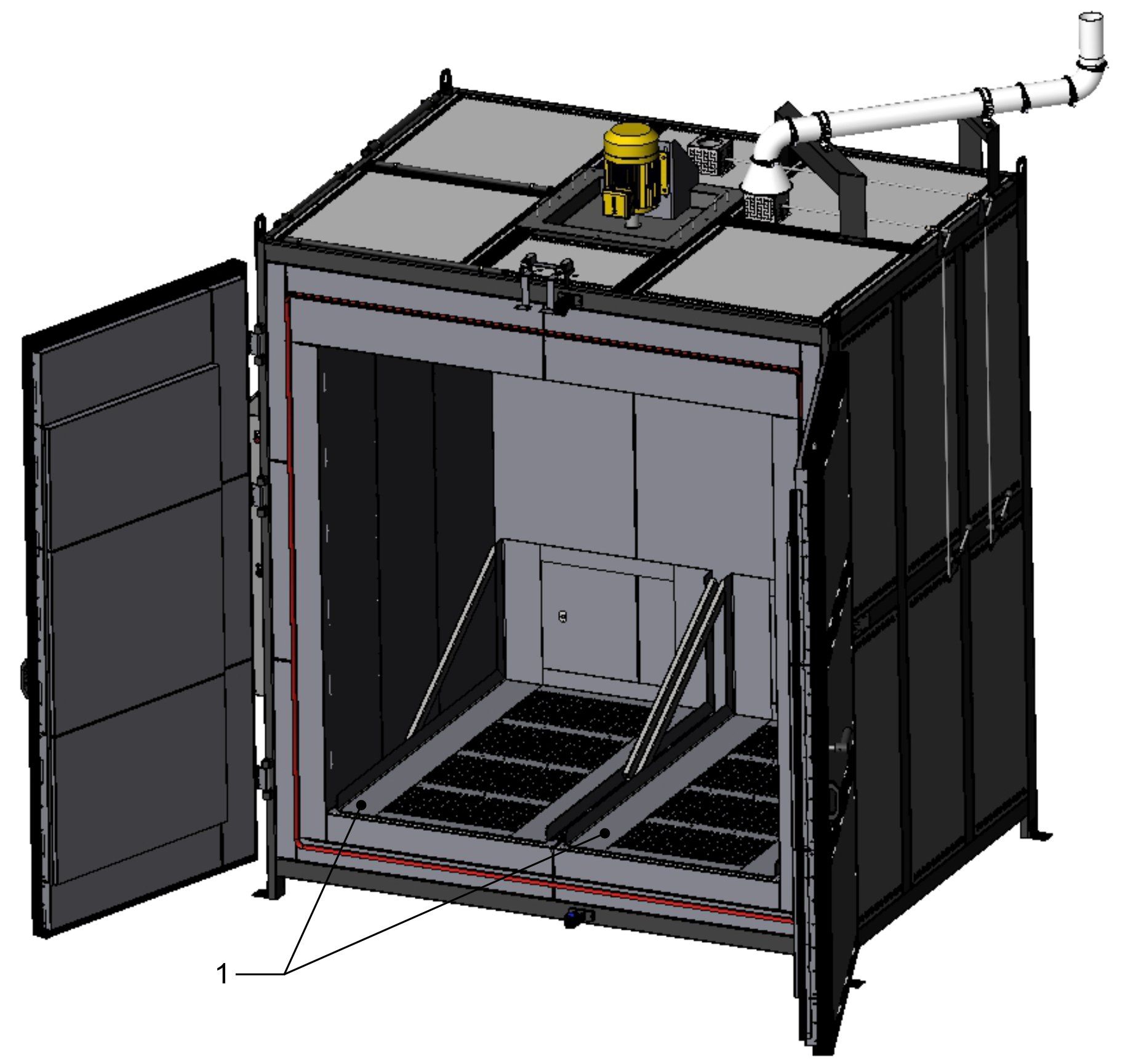

Convection oven for even temperature distribution

Many modern chamber furnaces are equipped with a convection system. This technology ensures homogeneous heat distribution throughout the entire furnace chamber – even for complex or delicate components. Advantages of the convection chamber furnace:

Even heating: Avoidance of hotspots or cold zones.

Gentle processes: Ideal for components with tight tolerances or temperature-sensitive materials.

Reduced process times: Faster heating and cooling phases due to improved air circulation.

Recirculating air operation is particularly suitable for drying processes, coating preparations or industrial heat treatments with high quality requirements.

Technical equipment and options for chamber furnaces

A professional industrial furnace like a chamber furnace offers a wide range of equipment options. Standard technical features include:

Temperature range: from 180 °C to 950 °C – optionally even higher

Heating methods: electric or gas-powered – depending on the energy source and application

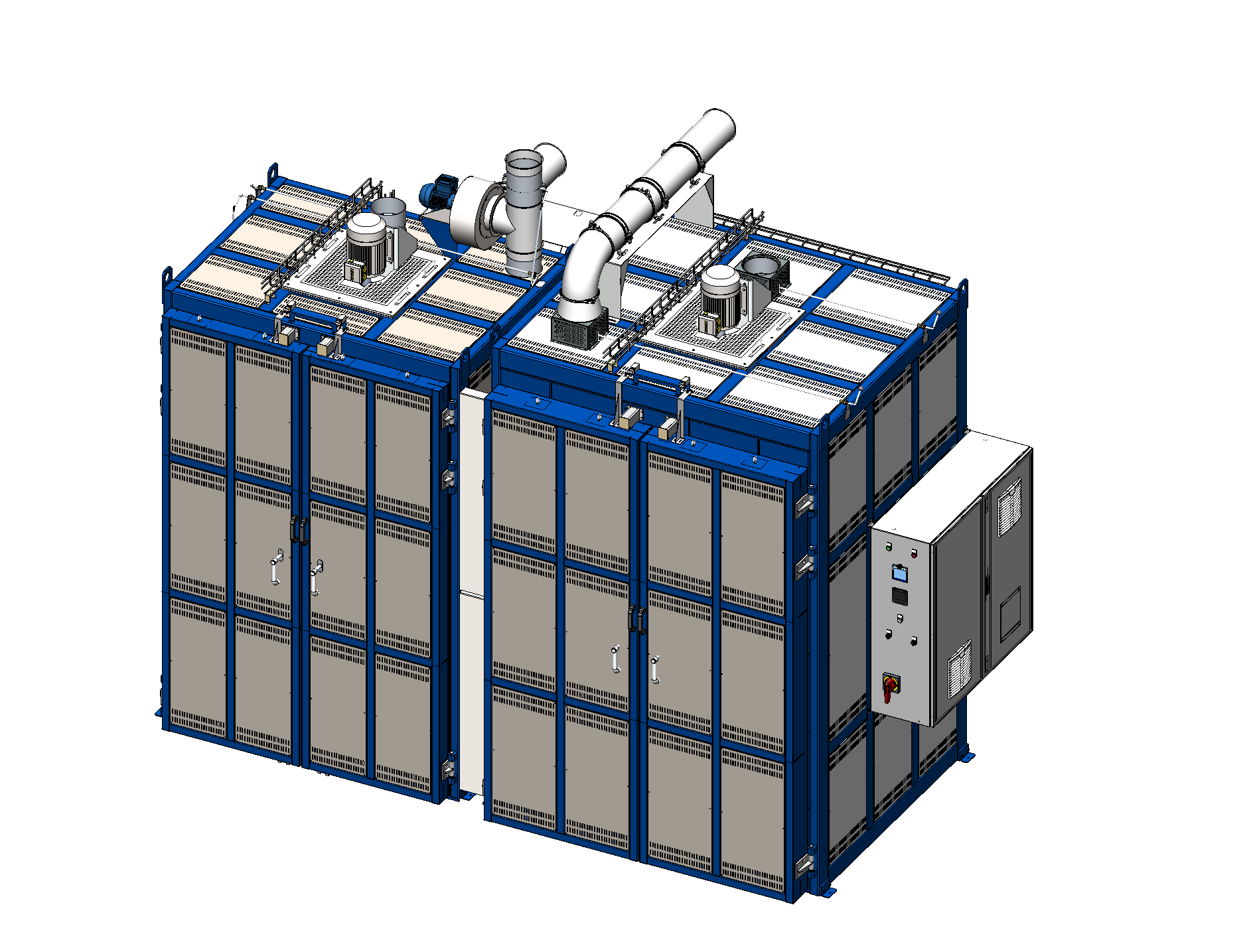

Volumes: from compact laboratory sizes to large-volume industrial furnaces

Control systems: digital PID controllers, PLC control, interfaces for process data acquisition

In addition, special equipment such as inert gas atmospheres, vacuum chambers, automated feeding systems or cooling zones can be integrated.

Custom-made industrial furnaces from experienced industrial furnace manufacturers

The requirements for an industrial furnace vary depending on the industry and application. For this reason, modern industrial furnace construction offers both standardized models and custom-developed solutions. Whether a one-off for specific heat treatment processes or a series-produced furnace with proven technology – quality, reliability, and efficiency are always paramount.

An experienced provider of industrial furnace construction, such as ENA Industrieofenbau GmbH, develops and manufactures chamber furnaces precisely according to customer specifications. Comprehensive consultation, precise planning, and high-quality implementation ensure compliance with all industry-specific standards and requirements.

Expansion through additional oven types

In addition to chamber furnaces, the portfolio of modern industrial furnace manufacturers also includes:

Continuous furnaces: For continuous processes with high part throughput

Hood furnaces: For uniform heat treatment of large components or stacks

Drawer ovens: Particularly space-saving and ergonomic

Special furnaces: Individually designed for specific requirements, e.g. for vacuum brazing or surface treatment

The combination of different oven types makes it possible to thermally optimize and fully automate entire production processes.

In conclusion, a chamber furnace is an indispensable element in professional industrial furnace construction. It offers maximum flexibility, energy efficiency, and process reliability. Companies that prioritize quality and reliability will find an optimal solution for their heat treatment processes in individually designed chamber furnaces – whether in series production, in the laboratory, or in specialized manufacturing.