ENA Custom-made industrial furnaces and industrial furnace construction for the highest demands

ENA industrial furnaces for the highest demands

Industrial furnaces from ENA – tailor-made solutions for the highest requirements

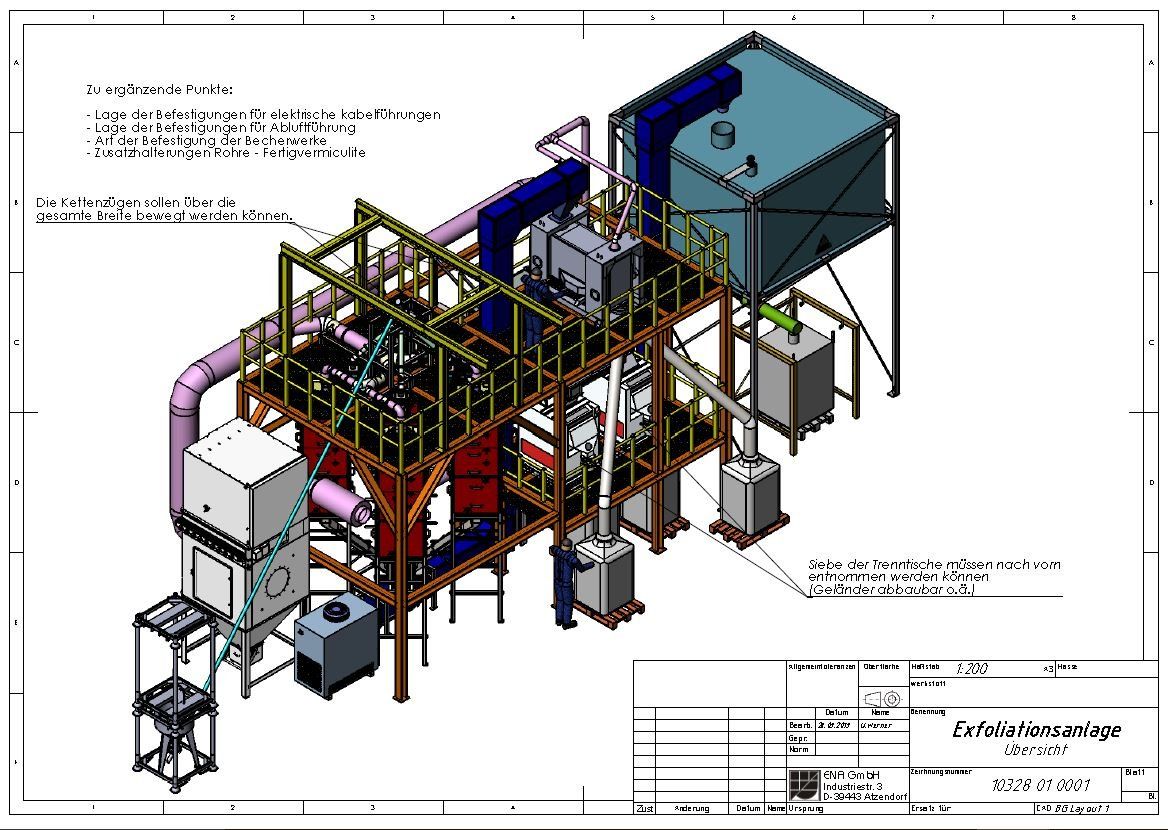

ENA Industrieofenbau GmbH develops and manufactures state-of-the-art industrial furnaces that stand for efficiency, precision, and durability. Our systems, based on electrical energy technology, offer sustainable solutions for virtually all thermal processes – from 100 °C to over 1,850 °C. Our specialty furnaces even reach temperatures up to 10,000 K – ideal for the most demanding applications such as thermal plasmas.

Industrial furnaces for every process step – modular, efficient, individual

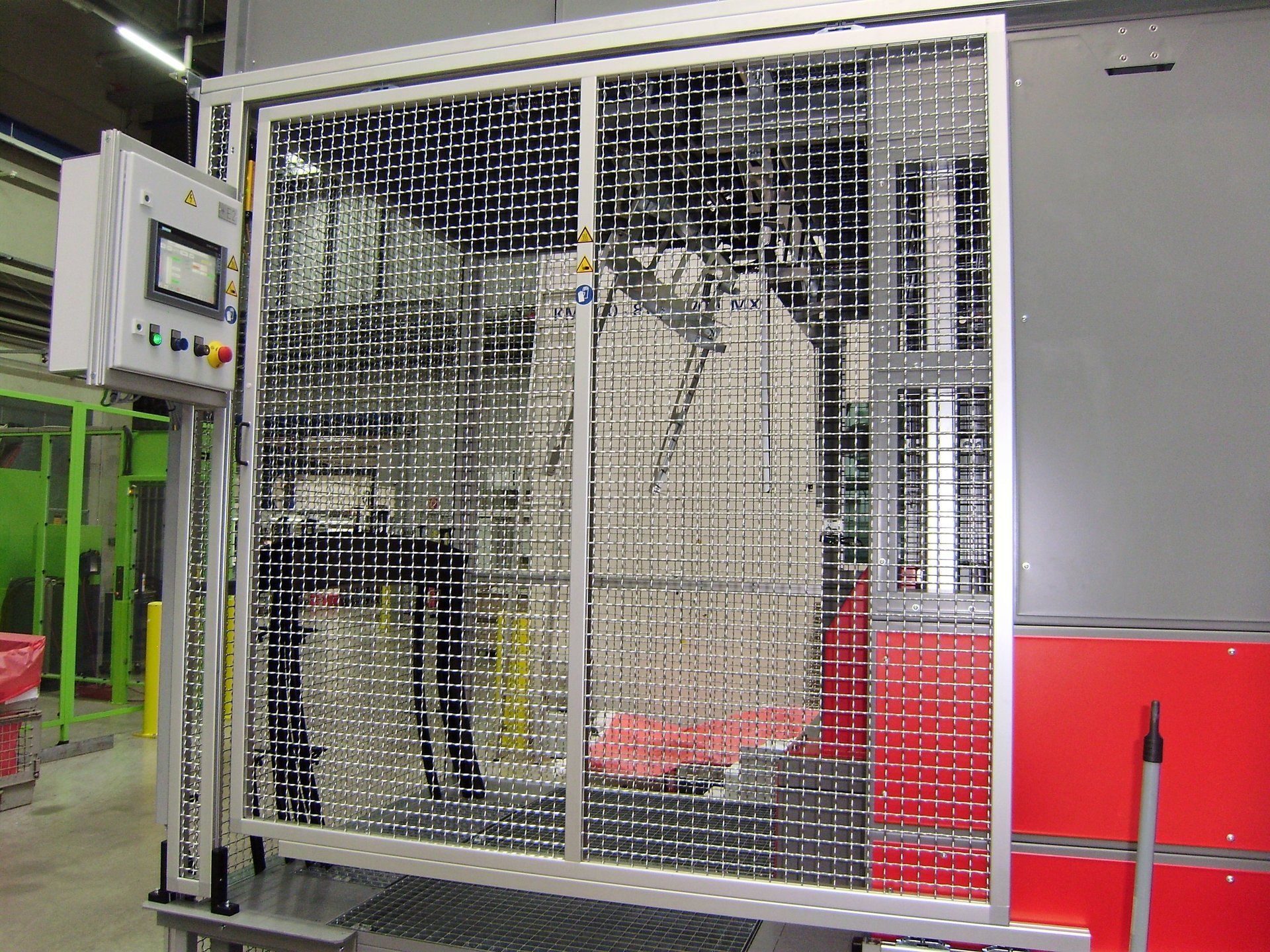

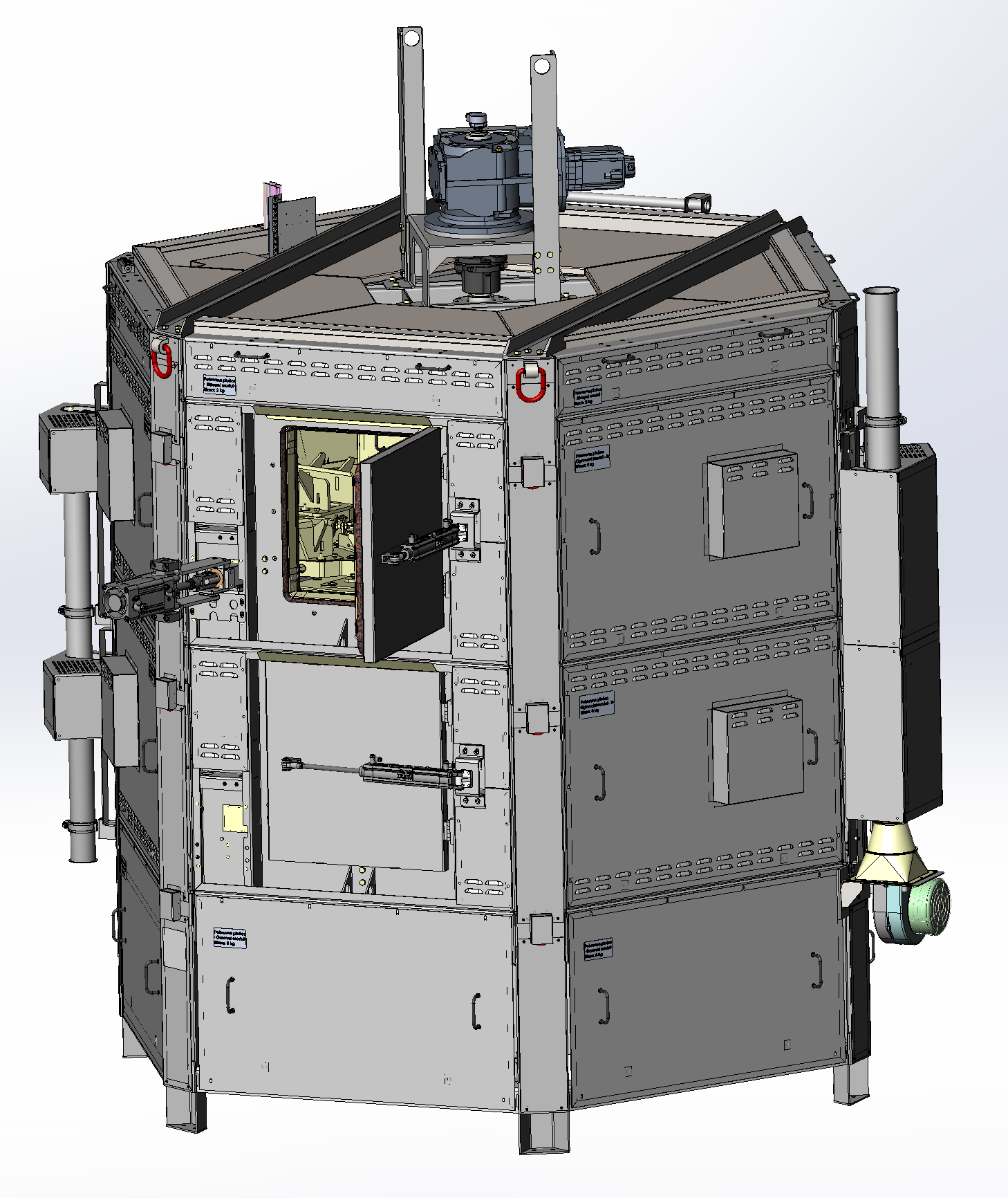

Our industrial furnaces cover a wide range of processes: drying, heating, tempering, annealing, hardening, sintering, and cooling. Our continuous furnaces, designed for continuous operation and perfectly integrated into existing production lines – both mechanically and software-wise – are particularly popular.

Depending on the application, we offer continuous furnaces with horizontal or vertical designs, convective or combined heating (e.g., electric gas). This makes our solutions particularly scalable and adaptable.

ENA – Your partner for energy-efficient industrial furnaces

Our industrial furnaces are manufactured exclusively to customer specifications – tailored to your materials, process requirements, and energy needs. We support you from consulting and process analysis through design and production to commissioning and after-sales service – all from a single source.

Our advantages at a glance:

Many years of experience in industrial furnace construction

Energy-efficient technologies with low operating costs

Development and production in Germany (“Made in Germany”)

Individual system concepts instead of standard solutions

Modern control and automation technology

Technical highlights of our industrial furnaces:

Temperature ranges: 100 °C to >1,850 °C

Special solutions: Plasma systems up to 10,000 K

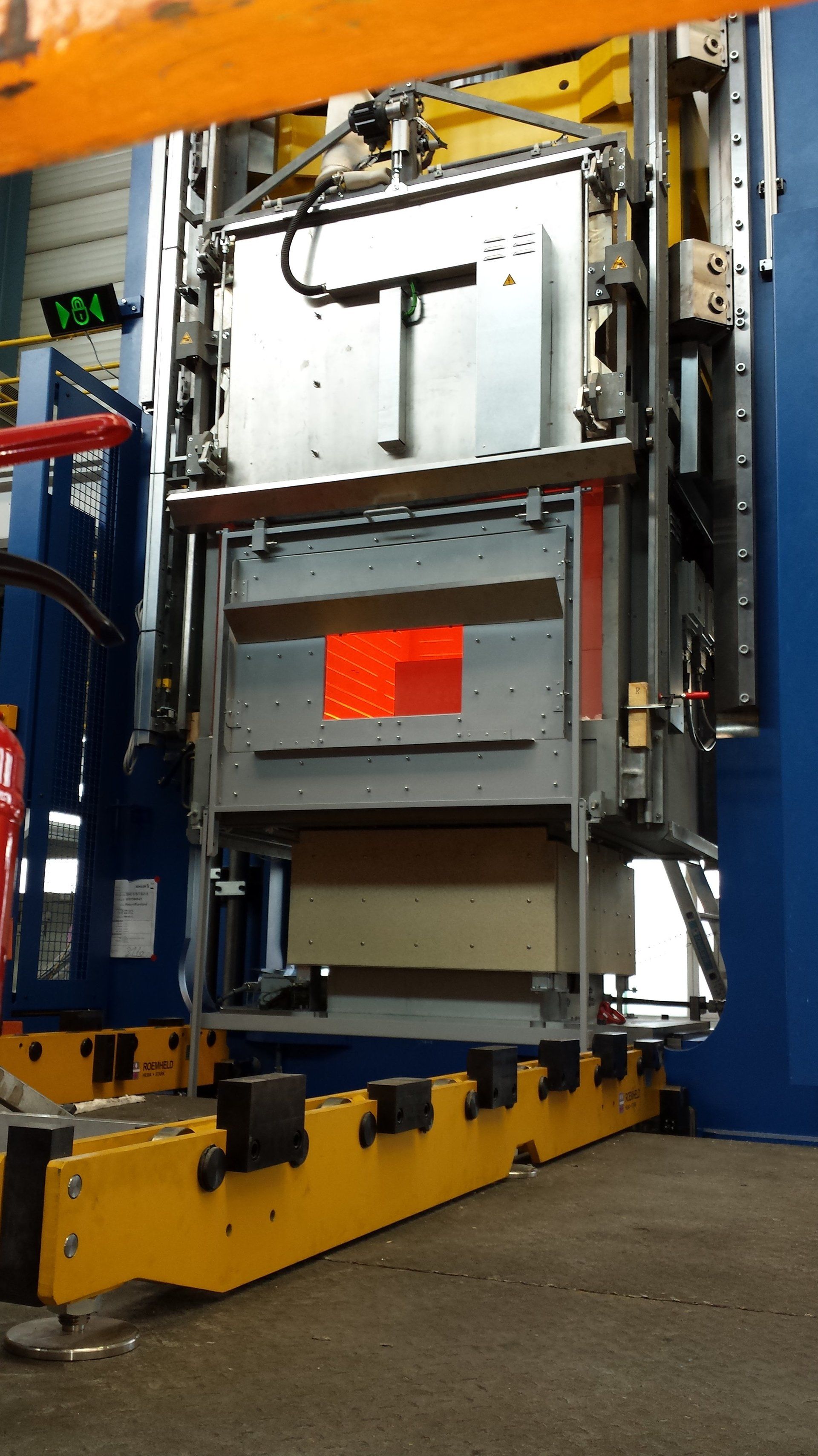

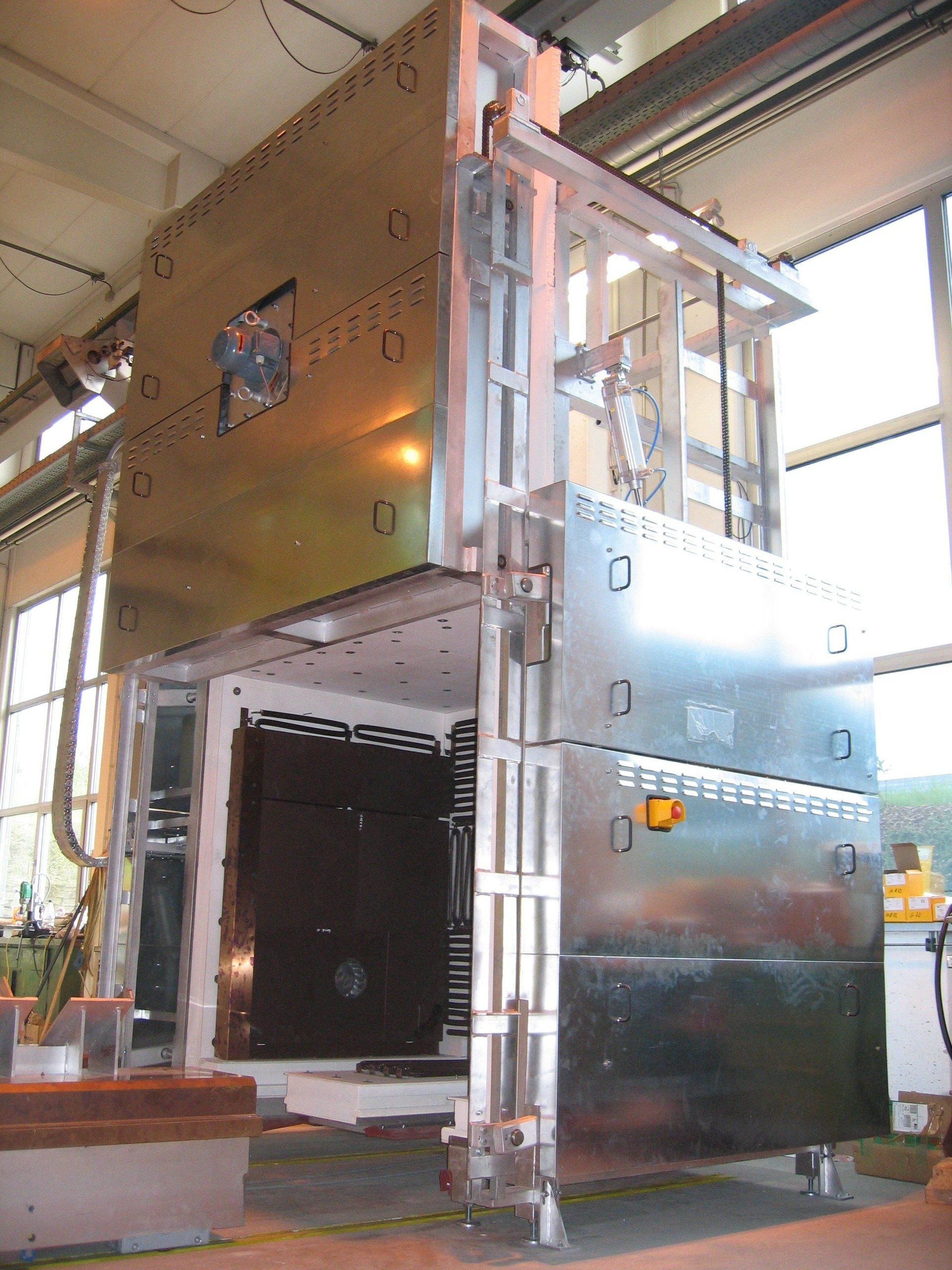

Furnace types: chamber furnaces, continuous furnaces, shaft furnaces,

Heating types: electric, infrared, inductive,

Operating modes: continuous or batch

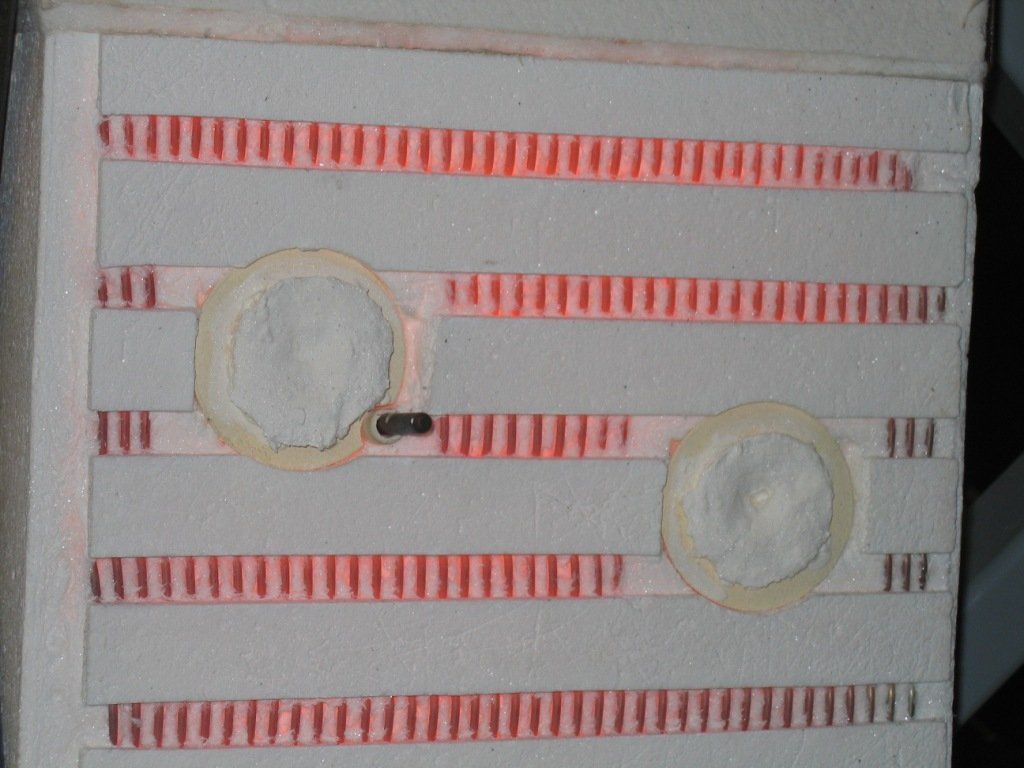

Insulation materials: high-temperature fiber, ceramic, vacuum plates

Looking for an industrial furnace? Request a quote now!

Whether it's an industrial furnace, continuous furnace, heat treatment plant, or specialty furnace – we deliver the right solution. Benefit from our customized planning and first-class quality.

👉 Request a non-binding offer now.

📞 We look forward to your challenge!

-

-

Tempering furnaces up to 650°C

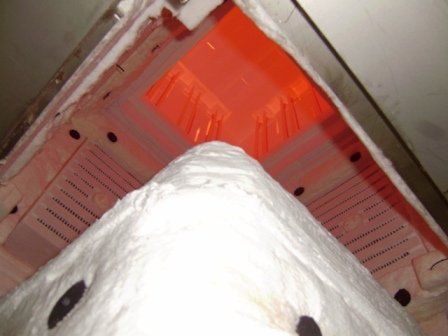

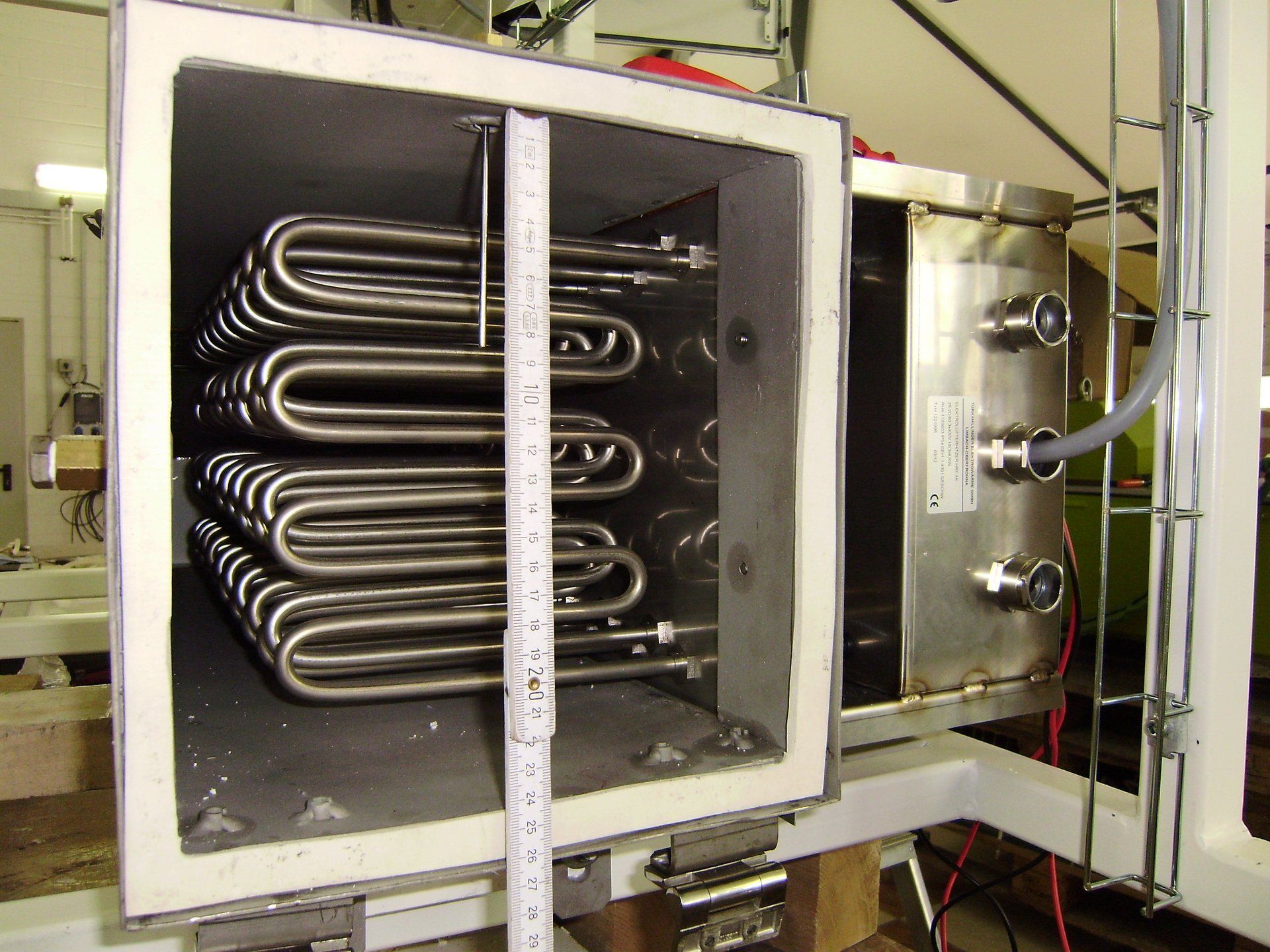

Tempering oven e.g. for 350°C -

Continuous furnaces up to 900°C

Continuous furnace e.g. for 200°C CFC components -

Chamber furnaces up to 1600°C

Chamber furnace e.g. for 350°C metal components -

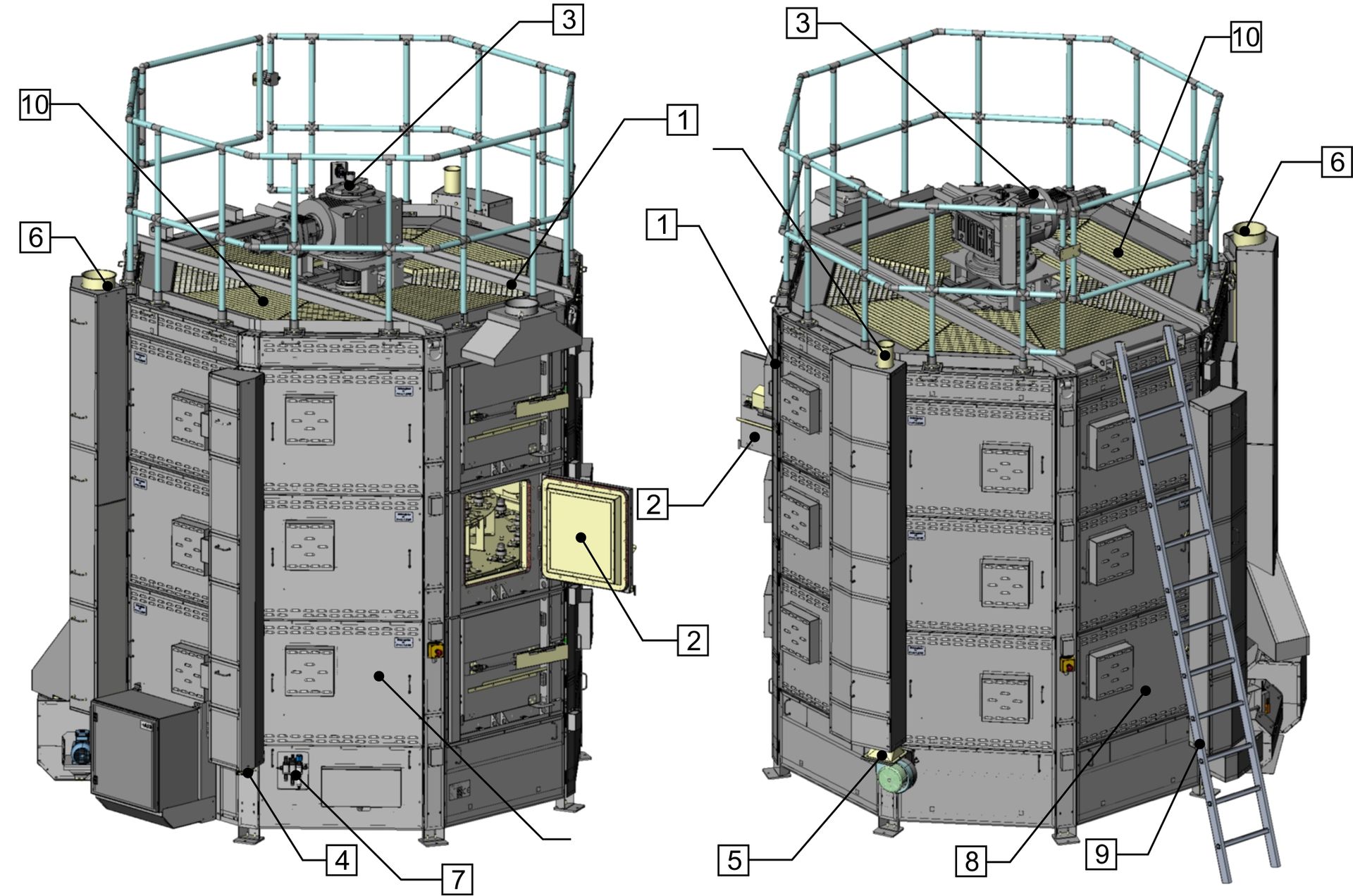

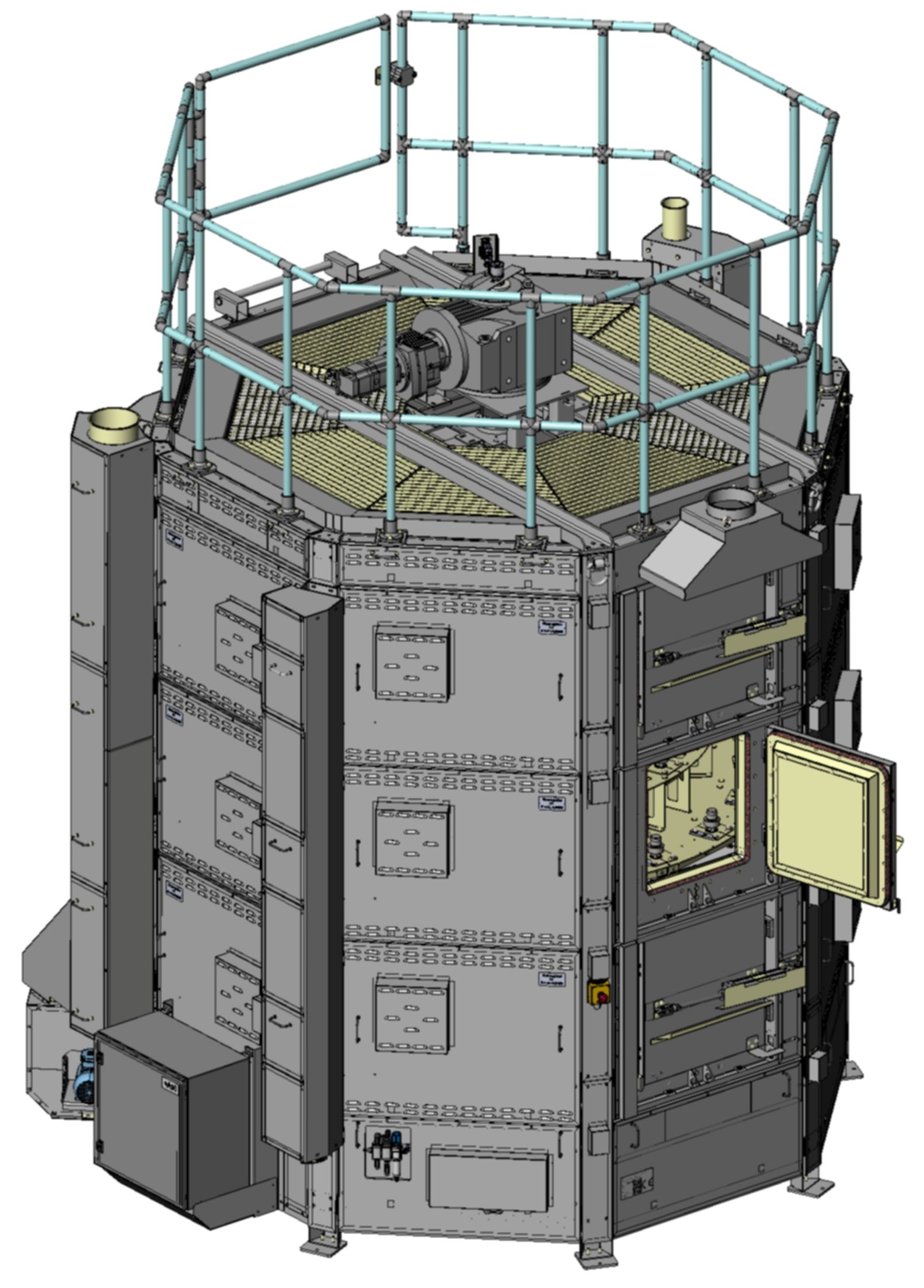

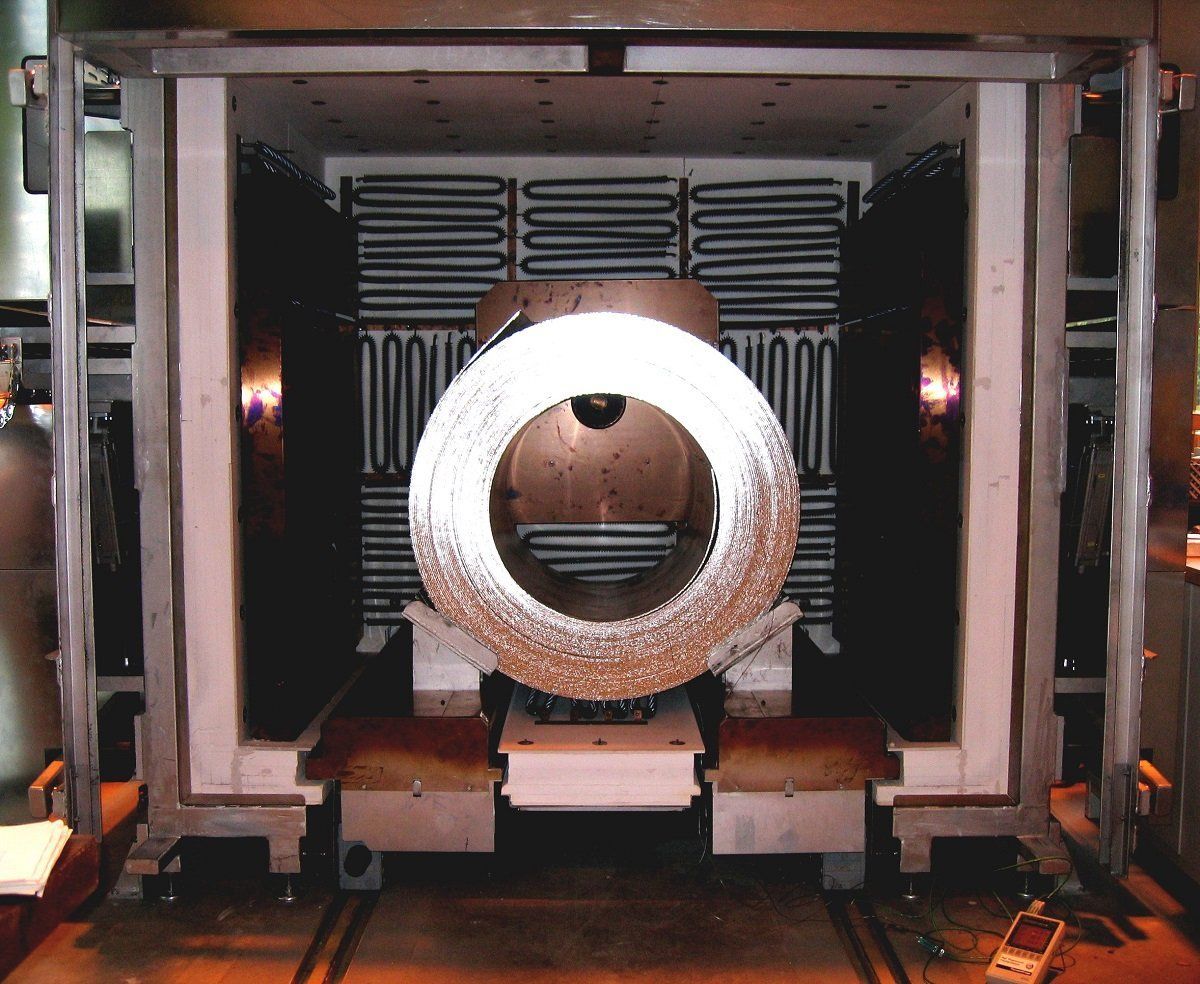

Hood furnaces up to 1850°C

Hood furnace e.g. for 1450°C research -

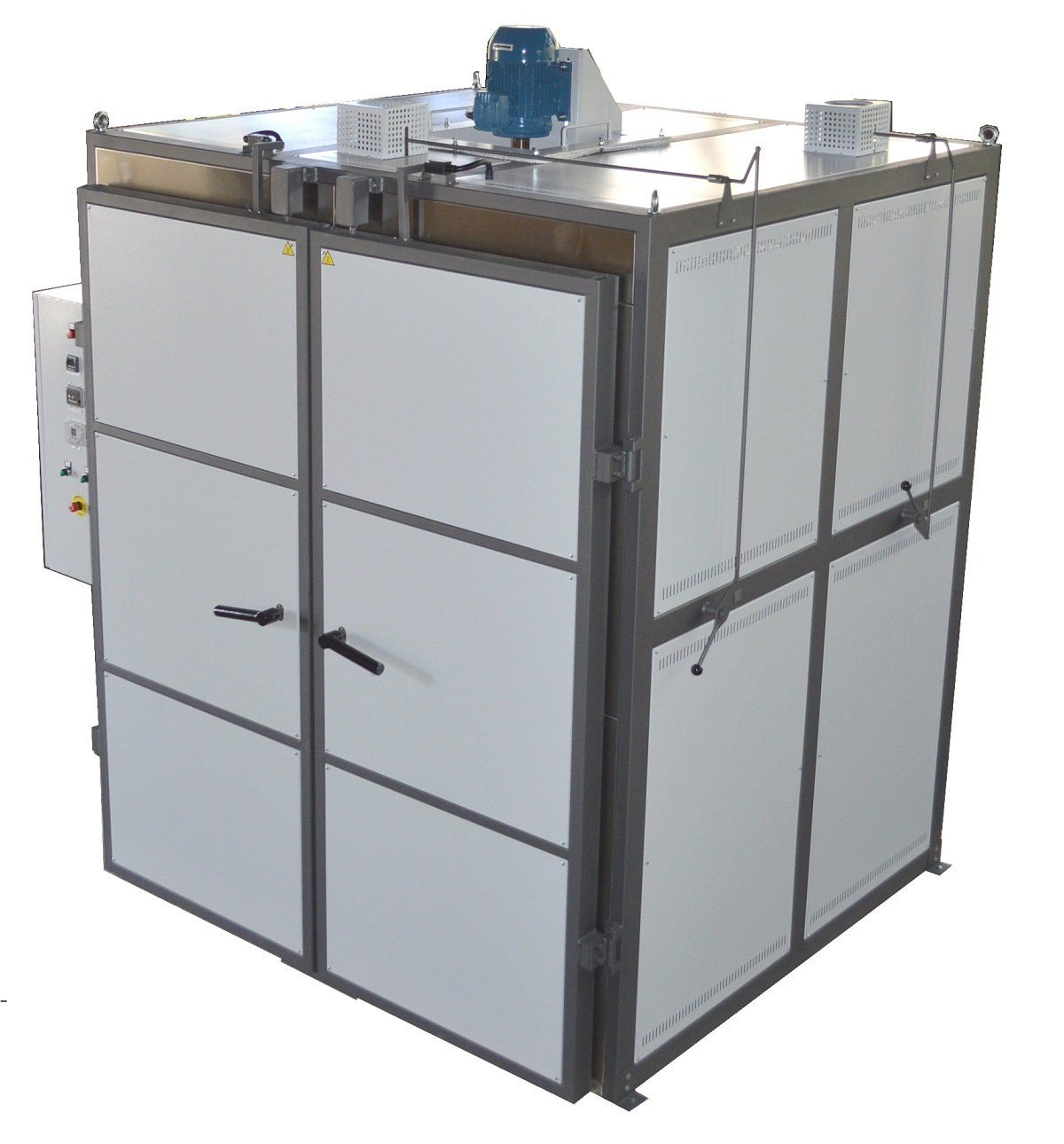

Chamber furnace convection oven

Chamber furnace e.g. for 350°C metal components -

Convection oven

Convection oven for plastics -

Convection drying oven

Convection drying oven -

Tunnel oven 1100°C

Tunnel oven 1100°C -

Hood furnace 950°C

Hood furnace 950°C for aircraft parts -

High-temperature furnace 1850°C

High temperature furnace 1850°C under N -

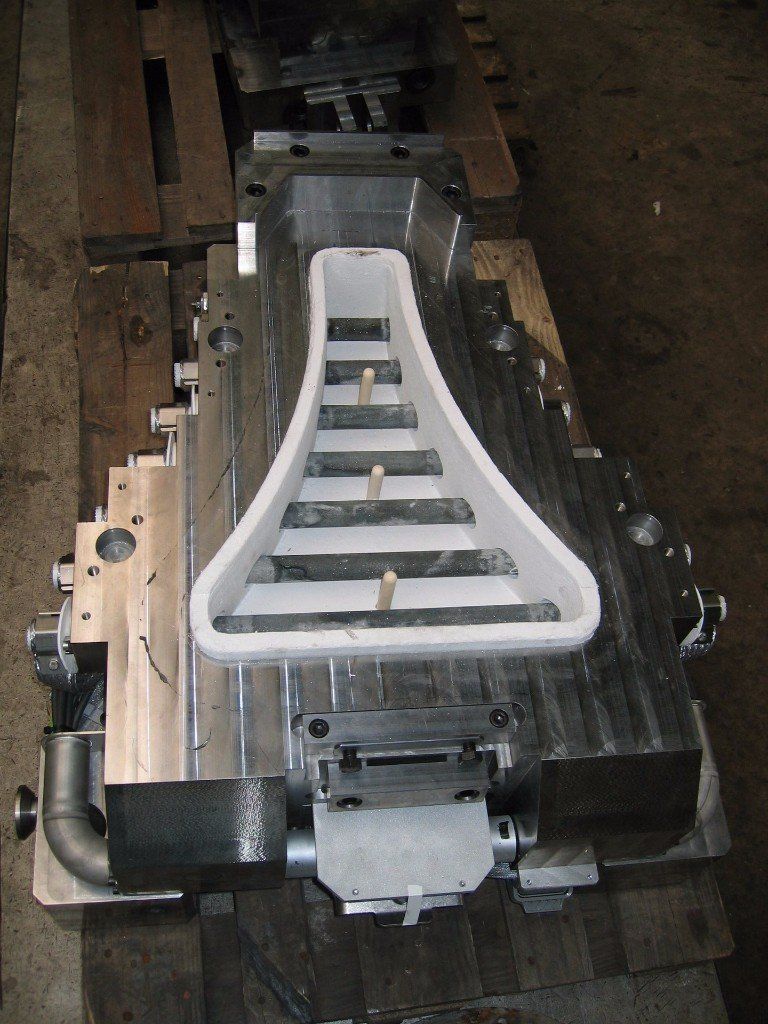

Al-Gießrinne 800 °C

Aluminum casting launder 800°C with ultrasonic treatment -

Vacuum furnaces 10^-6mbar/650°C

Vacuum furnaces 650°C for soldering processes